OEM Anti-Glare (AG) Glass Cover Printing Solutions: Durability Meets Clarity

Premium OEM Anti-Glare Glass Cover Printing solutions

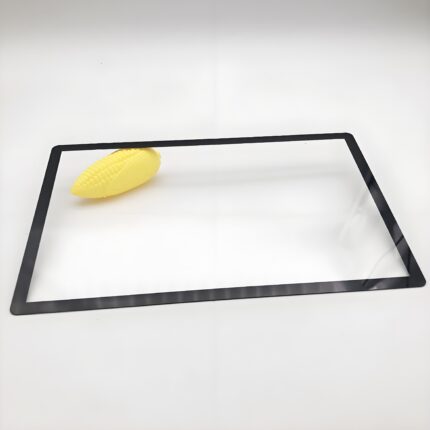

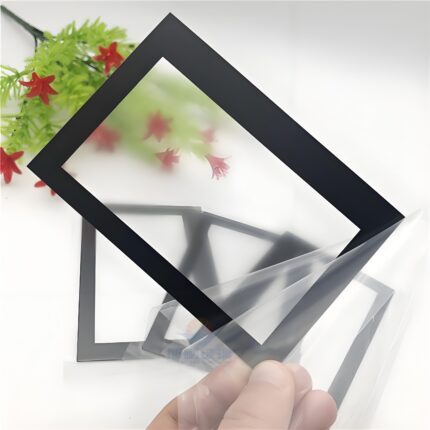

Tired of glare ruining your user experience? Our specialty is OEM anti-glare glass printing. We expertly silk-screen logos, borders, and icons onto high-quality AG glass, delivering a flawless, durable finish. The etched surface drastically cuts reflections and hides fingerprints, perfect for outdoor kiosks, medical devices, or industrial controls. Yes, there’s a tiny trade-off in light transmission versus clear glass, but the huge gain in readability under bright light is absolutely worth it. Let’s discuss your project needs and get you a perfect sample.

The Ultimate Guide to OEM Anti-Glare (AG) Glass Cover Printing Solutions: Durability Meets Clarity

If you’re sourcing electronic components, you know the cover glass is more than just a piece of protection. It’s the user’s primary point of interaction. In a world saturated with screens, reducing glare isn’t a luxury; it’s a necessity. This is where OEM Anti-Glare (AG) glass printing solutions become critical. But what exactly goes into a high-quality AG glass, and how does it compare to its transparent counterpart? Let’s break it down, not from a textbook, but from a practical manufacturing perspective.

What Exactly is Anti-Glare (AG) Glass, Anyway?

Let’s get straight to the point. Anti-glare glass isn’t about making the glass opaque. It’s about engineering its surface. We achieve the AG effect by treating one side of the glass with a specialized etching process. This creates a microscopically rough surface that scatters incoming light. Instead of a concentrated beam of light reflecting directly into your eyes (causing those annoying reflections), the light is diffused across many angles.

The result? Drastically improved readability under bright lighting conditions, whether you’re out in the sun or under harsh office LEDs. It also does a fantastic job of hiding fingerprints and minor scratches, which is a huge win for aesthetics and maintenance. For devices used outdoors, in medical settings, industrial control panels, or high-end kiosks, AG glass is pretty much the default choice. It’s all about enhancing usability.

Why Your OEM Silk Screen Printing Partner Matters More Than You Think

So you’ve got your AG glass substrate. Now what? This is where the magic of silk screen printing comes in. This isn’t a simple decoration step; it’s a core part of the product’s functionality and brand identity.

A top-tier OEM partner doesn’t just slap ink on glass. They engineer the printing process. We’re talking about printing the borders, logos, indicator icons, and touch button legends onto the backside of the AG-etched glass (the #2 surface in industry terms). This serves two crucial purposes: it protects the print from abrasion and creates a stunning visual depth.

The challenge? Printing on that rough AG surface. It requires specific ink formulations with superior adhesion properties and a printing team that has a deep understanding of mesh count, squeegee pressure, and curing parameters. Get it wrong, and you end up with poor opacity, light bleed, or ink that chips off. This is why choosing an OEM partner with proven expertise in AG glass printing is non-negotiable. They turn a component into a seamless user interface.

AG vs. Clear Glass: A Technical Face-Off on Transmittance and Refraction

This is the heart of the matter. You need to know how your choice of glass impacts optical performance. Here’s the real-world lowdown.

Transmittance: The Battle of Light Output

Simply put, transmittance is the percentage of light that passes through the glass. Think of it as the measure of how “clear” your glass is.

-

Clear Glass: This is the champion of pure light transmission. A typical clear, chemically strengthened glass like Gorilla Glass can have a visible light transmittance of 91% or higher. It offers minimal loss, making colors pop with maximum vibrancy and brightness. It’s the go-to for consumer devices where color fidelity is paramount, indoors.

-

AG Glass: Here’s the trade-off. That same microscopic etching that scatters light for anti-glare also causes a small amount of light to be scattered away from the viewer. A high-quality AG treatment will typically have a visible light transmittance in the range of 88% to 92%. Wait, that can be similar? Yes, but the perception is different. The diffused light can sometimes create a very slight “haze” effect (measured by a separate haze value), which can perceptually soften the image sharpness ever so slightly compared to perfectly clear glass. The key for a good OEM is to use a controlled, uniform etch that maximizes transmittance while achieving the desired anti-glare effect.

Refraction: Bending Light vs. Scattering It

Refraction is all about how light changes direction as it passes through a material.

-

Clear Glass: It has a smooth surface and a uniform internal structure. Light refracts (bends) at a predictable angle when it enters and exits. This is why you get sharp, mirror-like reflections. The refractive index for soda-lime glass is a constant ~1.51.

-

AG Glass: The game changes completely. The etched surface isn’t smooth, so it doesn’t create a single, coherent reflected image. Instead, the light hits the uneven surface and is reflected and refracted in countless random directions. This is the core mechanism behind breaking up glare. The refractive index of the glass material itself remains ~1.51, but the surface topography manipulates the light’s behavior entirely. It’s not about bending light predictably; it’s about controlling its diffusion.

Key Considerations for Your AG Printing Project

When you approach an OEM, be ready to discuss these specifics:

-

Glare Level: Often specified by haze percentage (e.g., 10%, 20%, 30% haze). Higher haze = more diffusion = stronger anti-glare.

-

Ink System: Epoxy or UV-cure? Colors? Need optical bonding compatibility?

-

Cover Lens Design: Complex shapes with cutouts? 2.5D or 3D edges?

-

Application: Is it for a veterinary monitor, a beach-side payment terminal, or a factory touchscreen? The environment dictates the specs.

Finding the Right OEM Manufacturing Partner

Don’t just go for the cheapest quote. Look for a partner with:

-

Proven AG Experience: Ask for samples and case studies.

-

In-House Capability: They should control the entire process from glass cutting, CNC machining, strengthening, AG etching, to printing and inspection.

-

Robust QA/QC: How do they measure transmittance and check for defects?

-

Engineering Support: They should be able to advise you on design for manufacturability.

Wrapping It Up: A Strategic Choice

Choosing between AG and clear glass with a printing solution isn’t about which is “better.” It’s about which is right for your product’s application. Clear glass offers unbeatable clarity for indoor use. AG glass provides critical usability in challenging lighting environments. The OEM partner you choose to execute the silk screen printing on this specialized material will make or break the final quality, durability, and user experience of your product. Invest the time to find a true expert, not just a vendor.