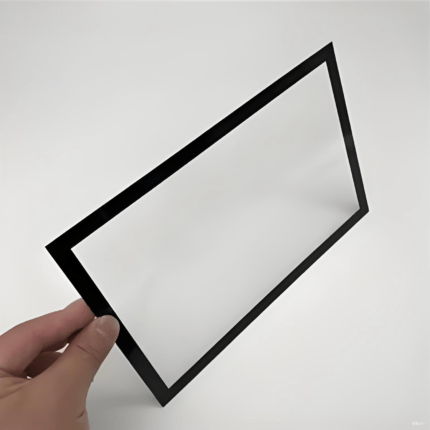

Custom Anti-Glare Cover Glass Transforming Light Management Through Surface Engineering

Walk into any brightly lit room or try to use your device outdoors, and you immediately understand why anti-glare technology matters. For fifteen years, we’ve been perfecting the science of light diffusion, developing AG cover glass that doesn’t just reduce glare but enhances the overall user experience. Our journey began when we noticed most anti-glare solutions either compromised too much on clarity or didn’t provide consistent performance across different lighting conditions.

The breakthrough came when we stopped thinking of anti-glare as just a surface treatment and started approaching it as complete light management system. Our engineers developed proprietary etching techniques that create precise micro-structures on the glass surface, scattering incoming light without significantly reducing transparency. The result? Glass that maintains excellent clarity while eliminating distracting reflections and fingerprints that plague conventional displays.

Precision Manufacturing for Consistent Performance

Creating effective anti-glare glass requires remarkable consistency in surface treatment. We’ve developed automated inspection systems that map surface topography at micron-level resolution, ensuring every batch meets exact specifications. Our production process involves multiple quality checkpoints where we measure haze levels, clarity, and diffusion characteristics to guarantee uniform performance across entire production runs.

What sets our process apart is how we tailor the anti-glare properties to specific applications. For medical displays requiring critical viewing, we create lighter etch patterns that minimize clarity loss. For outdoor kiosks or automotive displays, we develop more aggressive treatments that handle direct sunlight while maintaining touch functionality. Our technical team will work with you to find the perfect balance between glare reduction and optical performance for your specific use case.

Customization Options That Matter

Anti-glare is just the beginning of what we can do with our cover glass. We integrate AG treatment with other functionalities to create comprehensive solutions:

Combined AG/AR Coatings: For applications requiring both glare reduction and anti-reflection properties, we’ve developed hybrid solutions that manage light across multiple spectrums. These are particularly valuable for high-precision displays where color accuracy is critical.

Durability-Enhanced AG: Standard anti-glare treatments can sometimes reduce surface hardness. Our modified processes maintain scratch resistance while achieving excellent glare reduction, making them ideal for applications requiring frequent cleaning or heavy use.

Touch-Optimized Surfaces: We’ve engineered AG treatments that actually enhance touch sensitivity by reducing finger friction while maintaining the natural feel of glass. This is particularly valuable for devices requiring precise touch input.

Technical Specifications

| Parameter | Standard AG | Premium AG | Testing Method |

|---|---|---|---|

| Haze Level | 3-25% | Custom range | ASTM D1003 |

| Clarity | >90% | >95% | Laser-based measurement |

| Reflectivity | <2.5% | <1.5% | Spectrophotometer |

| Surface Roughness (Ra) | 0.1-0.8μm | Custom range | Surface profilometer |

| Hardness | ≥6 Mohs | ≥7 Mohs | Scratch test |

| Optical Transmittance | >89% | >91% | ASTM D1003 |

| Fingerprint Resistance | Class B | Class A | Oil contact angle |

| Chemical Resistance | Good | Excellent | Acid/alkali exposure |

| Abrasion Resistance | 5000+ cycles | 10000+ cycles | Taber abrasion test |

Application-Specific Solutions

Medical Imaging Displays: We’ve developed specialized AG glass that reduces glare from overhead lighting without compromising the grayscale differentiation needed for diagnostic accuracy. Our medical-grade solutions withstand frequent cleaning with harsh disinfectants while maintaining their anti-glare properties.

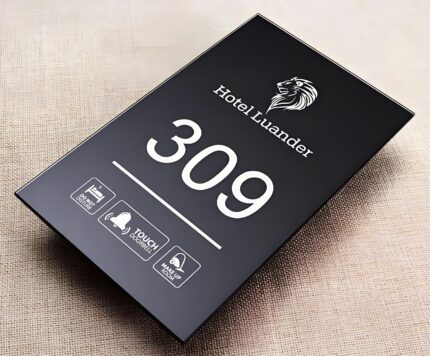

Automotive Center Stack Displays: For automotive applications, we create AG glass that handles sunlight from multiple angles while maintaining touch functionality. Our solutions meet automotive temperature requirements and incorporate vibration-resistant mounting options.

Outdoor Kiosks and POS Systems: Our heavy-duty AG treatment stands up to direct sunlight and frequent public use while maintaining clarity and touch sensitivity. We can integrate vandal-resistant properties for high-traffic installations.

Consumer Electronics: For laptops, tablets, and smartphones, we offer AG solutions that reduce eye strain during extended use while maintaining the premium look and feel consumers expect. Our treatments are particularly popular for devices used in educational and professional settings.

Why Our AG Glass Stands Apart

The difference is in the details – literally. While many suppliers simply apply standard etching processes, we customize the surface topography for each application. Our micro-structures are engineered to scatter light at specific angles relevant to how your device will actually be used. This attention to detail results in better performance where it matters most.

We also understand that anti-glare treatment affects other properties. Our engineers consider how the AG treatment will interact with touch functionality, coating adhesion, and assembly processes. This holistic approach prevents surprises during manufacturing and ensures smooth integration into your products.

Partnering for Optimal Results

The best AG solutions come from early collaboration. When we’re involved during the design phase, we can optimize the glass for your specific display technology, lighting conditions, and user interaction patterns. Our technical team will provide samples with varying haze levels and surface characteristics, helping you find the perfect balance for your application.

We maintain full transparency throughout the process, sharing test data and performance metrics so you understand exactly what you’re getting. Our quality control documentation provides traceability for every production batch, giving you confidence in consistent performance.

Experience the Difference

See for yourself how our custom AG cover glass can transform your product’s usability. Contact us to request samples tailored to your specific requirements and test them in your actual application environment. Our technical team will work with you to optimize the solution until it’s perfect for your needs.