Tempered Glass Cover Lens

Cover lens, also named cover cover lens or strengthened optical glass, role as outermost part of touchscreen to be a proctection layer.

They made from ultra thin flat glass under series of treatments like cutting, CNC, coatings, tempering, printing, tape etc. The cover glass isn’t only impact, scratch and dirt(oil, dust, grease etc.) but also increases the light trasmittance.

Cover Lens Introduction

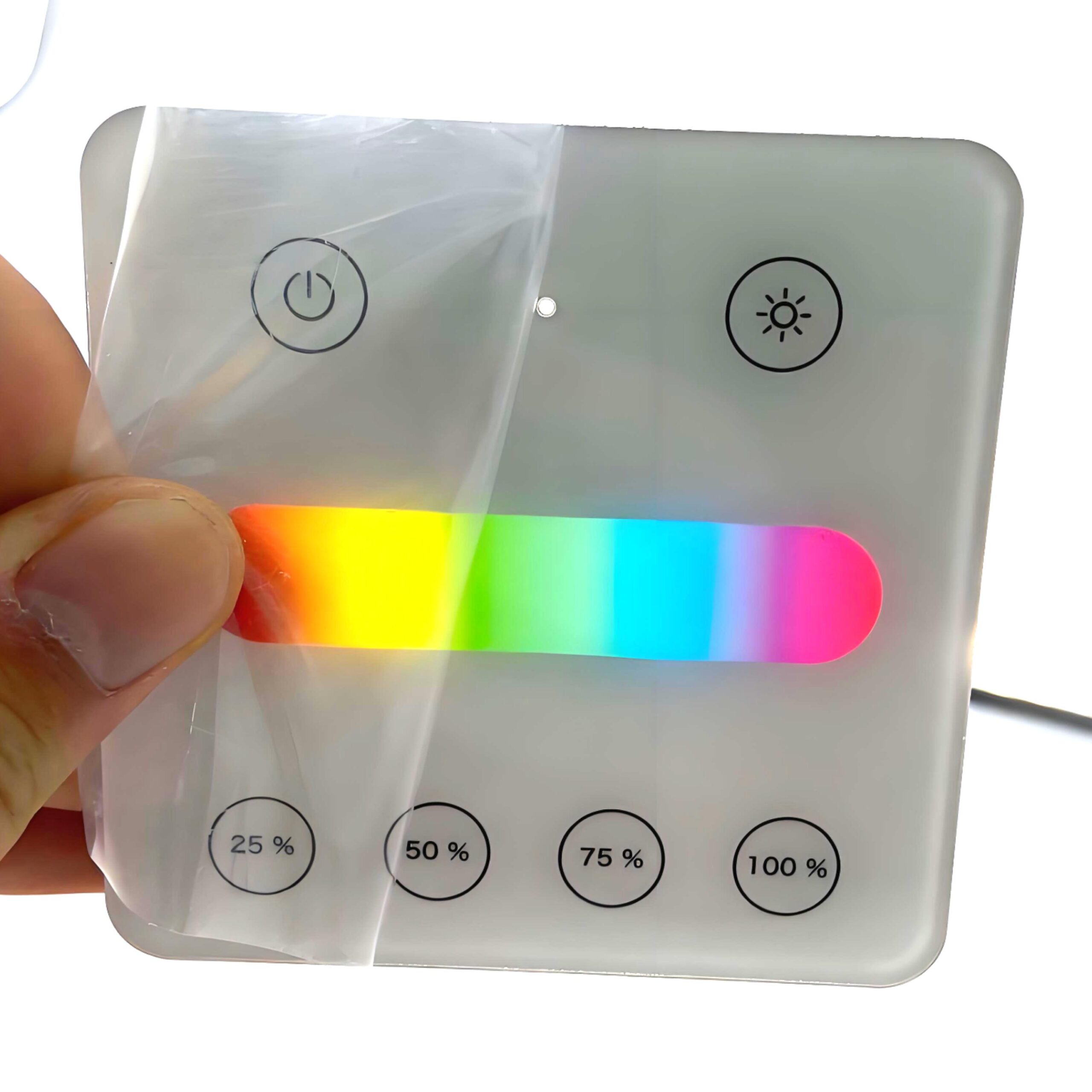

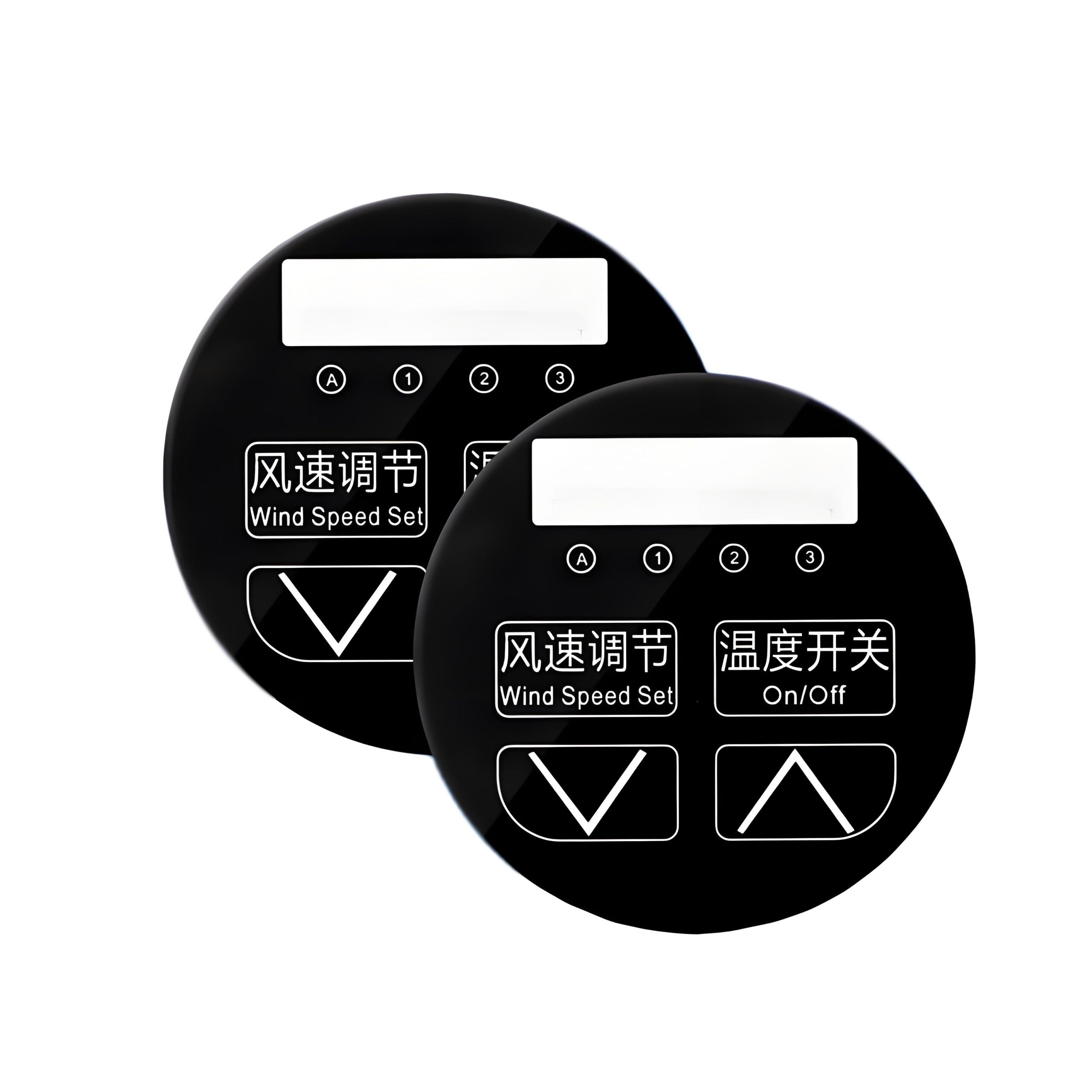

Cover lens application

Display: The cover lens used as outmost part for LCD, OLED, LED, and other display technologies.

Touch screen: As a protective layer, high hardness and scratch resistance.

Solar cell: As a substrate or packaging material.

Optical component: Used for lenses, prisms, and other optical devices.

Electronic packaging: Used for encapsulating microelectronics and optoelectronic devices.

Material

The cover lens substrates(after chemical toughened): Electronic grade.

The sodalime glass(Hardness 6H, cheaper), aluminum silica glass(Hardness 7-9H).

Different brands for free selection.

Printing

The ink selection depends on different application scenarios.

Indoor purpose usually use common low temperature ink, it’s a low cost option, but not UV resistance.

Outdoor purpose usually use UV ink(good UV light absorb capability) or high temperature ink(ceramic ink) to avoid yellowiesh / peel off due to expose under the sun.

The UV ink(low temperature also) can peel off when use hardware like knife. But high temperature won’t peel off except hurt glass body.

The high temperature ink suitable for glass thickness more than 2mm(thermally tempered) but light can pass. Then another layer of low temperature ink should be applied behind it.

But UV ink(low temperature ink also) is more colorful, so they become more commonly option.

Coating

The cover lens regular use coatings including AR(Anti-reflective), AF(Anti-fingerprint) and AG(Anti-glare).

AR coating: The regular thin glass transmittance is 90% above, single side of glass apply AR coating can improve 3~4%, both sides will be 96% in total.

AF coating: It reference from lotus effect good at anti-fingerprint, anti scratch and easy clean usually for touch the screen purpose.

Meanwhile it usually apply behind AR coating to protective the layer.

There are 2 ways to make the AF coating, one for plating(longer life but cost higher) and another one for spray(cheaper option).

AG coating: It’s a kind of acid etching process to get the glass surface a little matt. The principle is through scatter the light to prevent light(like sunlight)reflect to the eye directly.

More often it applied in outdoor purpose like navigators.

Tape

For cover lens glass, most of customers require tape adhesion service. We could provide after receive the tape requirement(like brand, waterproof, shapes etc).