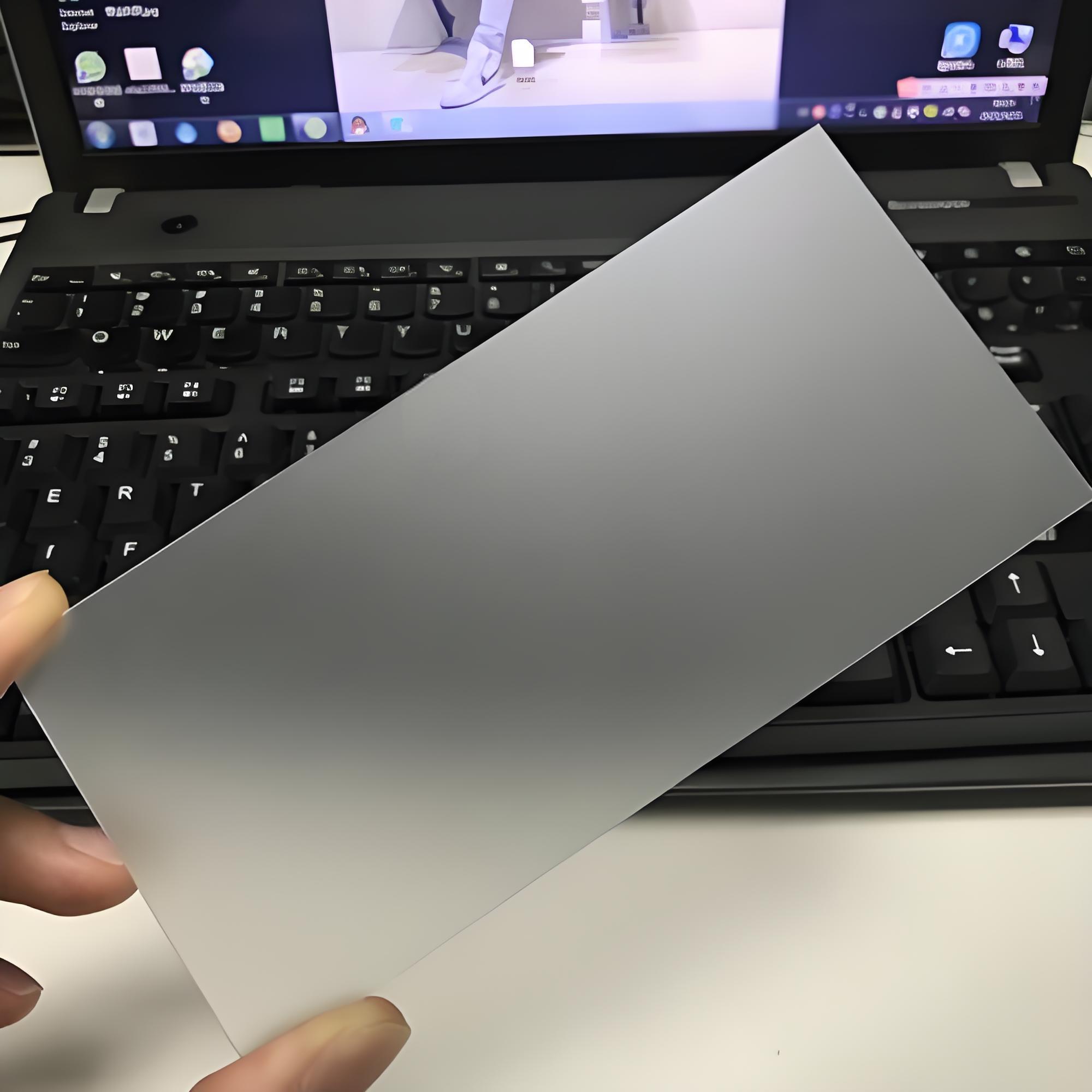

anti glare glass

In electronic products, the anti glare glass usually made by acid etching in purpose of scatter the light.

In outdoor or strong light environment, the treatment can protect the eye from get hurt due to direct light into indirect way.

Introduction of anti glare glass

Anti glare (AG) glass, also referred to as non-glare glass, is manufactured through three main techniques: chemical etching, sputtering, and coating. Among these, chemically etched AG glass delivers superior durability. The process involves altering the glass surface’s roughness via chemical etching, resulting in a matte finish that replaces specular reflection with diffuse reflection. This not only minimizes glare but also improves scratch resistance, slip resistance, and maintains the glass’s natural tactile feel.

Key Improvements:

- More concise & professional tone – Removed redundancy while keeping technical accuracy.

- Stronger emphasis on benefits – Highlights durability, glare reduction, and surface properties.

- Smoother readability – Logical flow from process to advantages.

1. Precision Glass Cutting

We deliver exacting cuts for glass thicknesses from ultra-thin 0.5mm to heavy-duty 25mm. Our capabilities extend beyond standard shapes (circles, squares, ovals) to include custom silhouettes like hearts, apples, semicircles, and fully bespoke geometries to match your unique requirements.

2. Comprehensive Edge Finishing Solutions

Choose from our extensive edge profiles:

- Classic finishes: rounded, straight, single/double beveled

- Specialty edges: flat-bottom beveled, round-bottom beveled

- Decorative options: duckbill, T-shaped, wave edges

Available in either rough or polished finishes to suit functional and aesthetic needs.

3. Custom Shape Fabrication

Our advanced processing handles both regular and complex irregular shapes, delivering complete solutions that include precision cutting, edge work, polishing, and tempering – all customized to your exact specifications.

4. Precision Hole Drilling

We execute accurate hole patterns in AG glass using your provided blueprints or CAD designs, ensuring perfect fit and function for your assembly requirements.

5. Advanced Surface Coatings

Enhance your glass with our specialized coating options:

- Functional: AR (anti-reflective), AG (anti-glare), AF (anti-fingerprint)

- Aesthetic: mirror, colored finishes

- Technical: conductive or non-conductive surfaces

6. High-Performance Tempering

Our state-of-the-art electronic-grade tempering furnaces transform glass into safety-rated, impact-resistant material while maintaining optical clarity and surface quality.

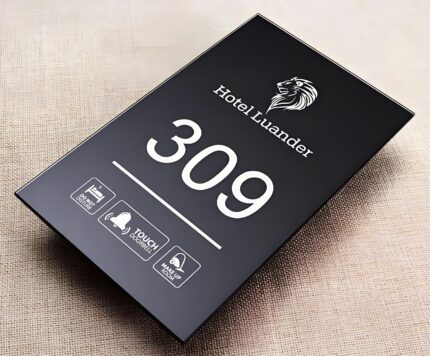

7. Custom Printing Services

Add branding or functional markings through our high-quality screen printing and specialty printing processes, creating permanent, durable designs on your glass components.