LCD Screen Chemical Toughened AR Electronic Glass

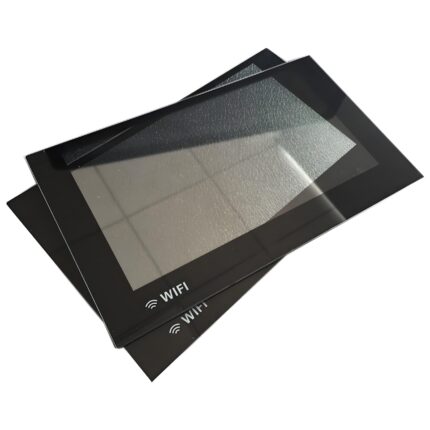

Chemical tempered AGC electronic glass, AR coating, silk screen print.

Electronic Glass(AR Coatings)

Electronic Glass Application

The glass is widely apply in different electronic devices as screen front.

It can protect the screen and other important parts, enhance appearance grade and provide various of functionalities.

Until now, glass already became indispensable part integrate into the products.

As digital signage expands from semi-outdoor to full outdoor environments, the challenges it encounters become increasingly diverse.

These include not only the growing demand for higher display brightness but also the need to withstand complex, all-weather external conditions.

The cover glass plays a critical role in ensuring optimal display performance and enhancing viewers’ visual experiences.

Weiman Capabilities

Optional thickness range: 0.25-22mm.

Size and shape: Customize per drawing.

Printing: Different colors and shapes can be selected.

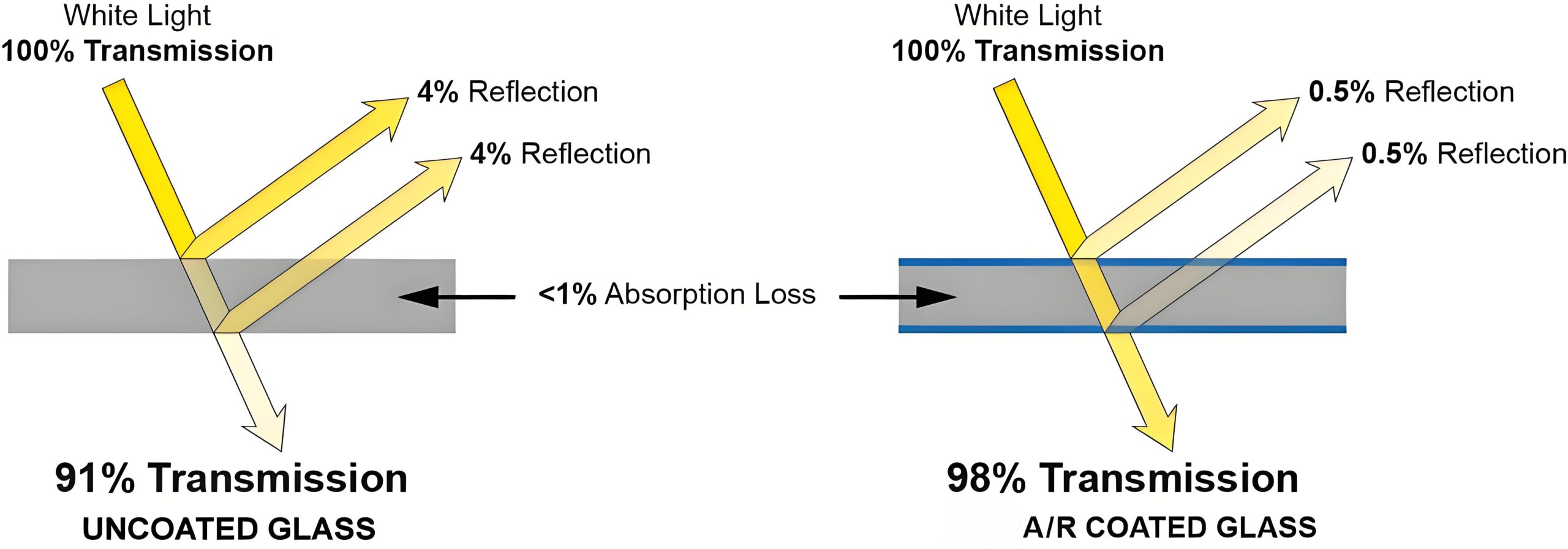

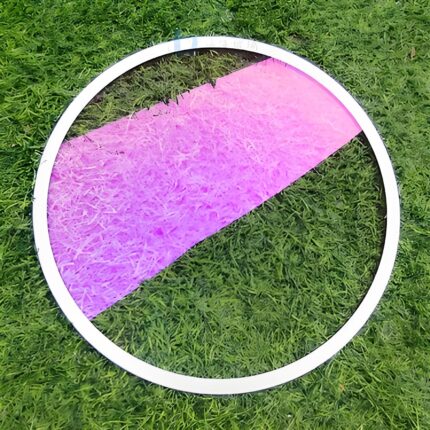

AR Coating

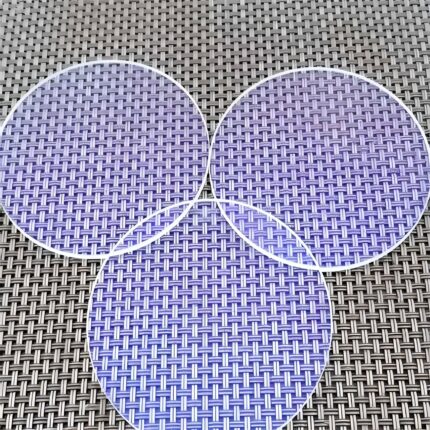

Option colors: Green, purple or blue.

Wavelength(visible light): 460-680nm(Regular)

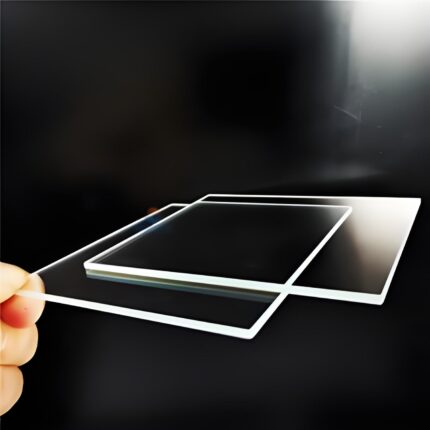

Anti-Reflective (AR) coated(Click here to get more information) electronic glass is a specialized type of glass, which undergoes a surface treatment with a unique material designed to minimize light reflection.

This treatment significantly enhances the clarity and transparency of light passing through the glass.

Weiman Tech specializes in the production of high-quality, ultra-clear AR coated toughened glass with exceptional light transmittance, achieving rates of over 98%.

This advance glass is suitable for a wide range of applications, including:

eyeglasses, camera lenses, LCD display screens, touch screens, face recognition devices, outdoor advertising displays, instrumentation equipment monitors, and automotive navigation systems.

Tempering Process(Electronic Glass)

Chemical tempering(Click here for more information) is a specialized process involving a chemical reaction known as ion exchange.

It’s the standard method employed for enhancing the mechanical properties of glass.

This technique is particularly critical for electronic glass applications, where stringent flatness requirements are essential to ensure seamless integration with mating components.

The precise flatness achieved through chemical tempering prevents the occurrence of gaps, thereby facilitating optimal assembly and performance in electronic devices.