Outdoor Screen AG Display Glass

Nowadays, the people more and more attach importance to health, especially the eye protection, AG treatment on glass application become more and more popular.

Display Glass(AG Treated)

In contemporary society, the display glass apply on electronic display devices gain widespread popularity.

Nonetheless, under certain conditions, such as:

1.Exposure to direct sunlight or high-brightness environments

2.The clarity of high-resolution displays can compromise, leading to image distortion.

In severe cases, this may even adversely affect human vision. The surface properties of OLED or LED display glass play a critical role in determining its light transmittance and reflectivity.

To mitigate reflections and ensure precise color reproduction, as well as deliver clear and vivid imagery.

Now display glass cover is often subject to specialize coating treatments to enhance its performance.

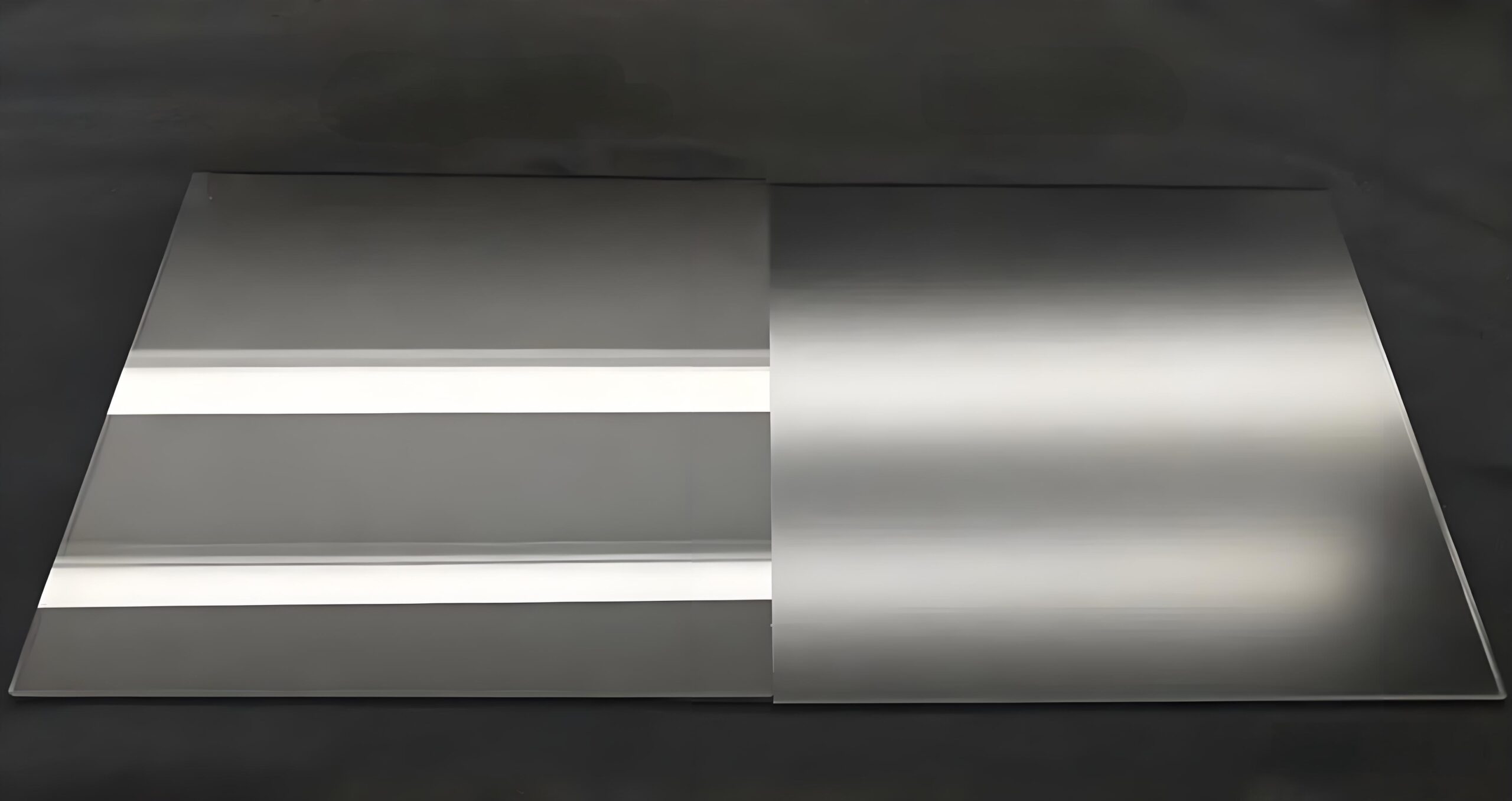

Anti-glare (AG, click here for more information) glass, renown for its ability to minimize environmental reflection interference.

Furthermore, etched AG glass has emerge as the material of choice for many electronic display applications, owing to its exceptional performance characteristics, including high durability, scratch resistance, and an optimized tactile texture that complements its aesthetic appeal.

This makes it an ideal solution for modern display technologies.

AG Treatment

In market, there are several kinds of methods to make surface matte like sandblast, acid-etching, frost ink and AG(anti glare) treatments.

Among them, AG is the most suitable method(Uniformity, strict grade control, no requirement on thickness and no shinny dot) apply in screen display purpose.

To check the AG effect, there normally 3 index(Transmittance, haze, gloss) which make it correctly.

The AG treatment on glass is mainly focus on 1.The texture of glass surface. 2.Light scattering to avoid strong sunlight/other light source direct to the eye cause harm/risk.

What Material Should Be Chosen As AG Display Glass

Because AG belongs to an individual treatment process on glass surface, then there’s no special requirement on glass material.

The selection of raw material should judge under application, also usage.

How Weiman Process The AG Display Glass

Every AG display glass manufacture by Weiman undergoes a rigorous QC at every stage of production.

From processing and storage to packaging and transportation, each step is meticulously monitor to ensure the highest standards are maintain.

Even for AG glass products that meet quality specifications, but improper packaging materials, inadequate methods, or suboptimal storage conditions can compromise the integrity of the AG surface, ultimately affecting its performance.

As a flexible professional OEM of AG glass covers, Weiman is commit to delivering exceptional quality, which ensuring that every piece of AG glass meets stringent performance and durability requirements.