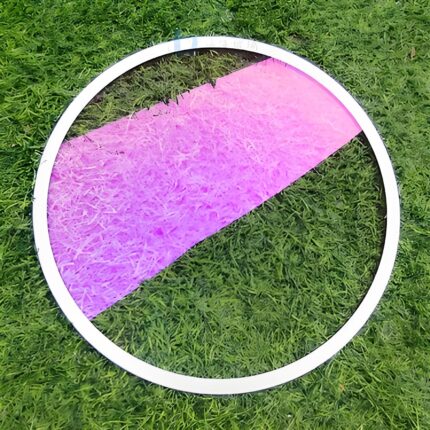

Circle Sight Electronic AR Tempered Glass

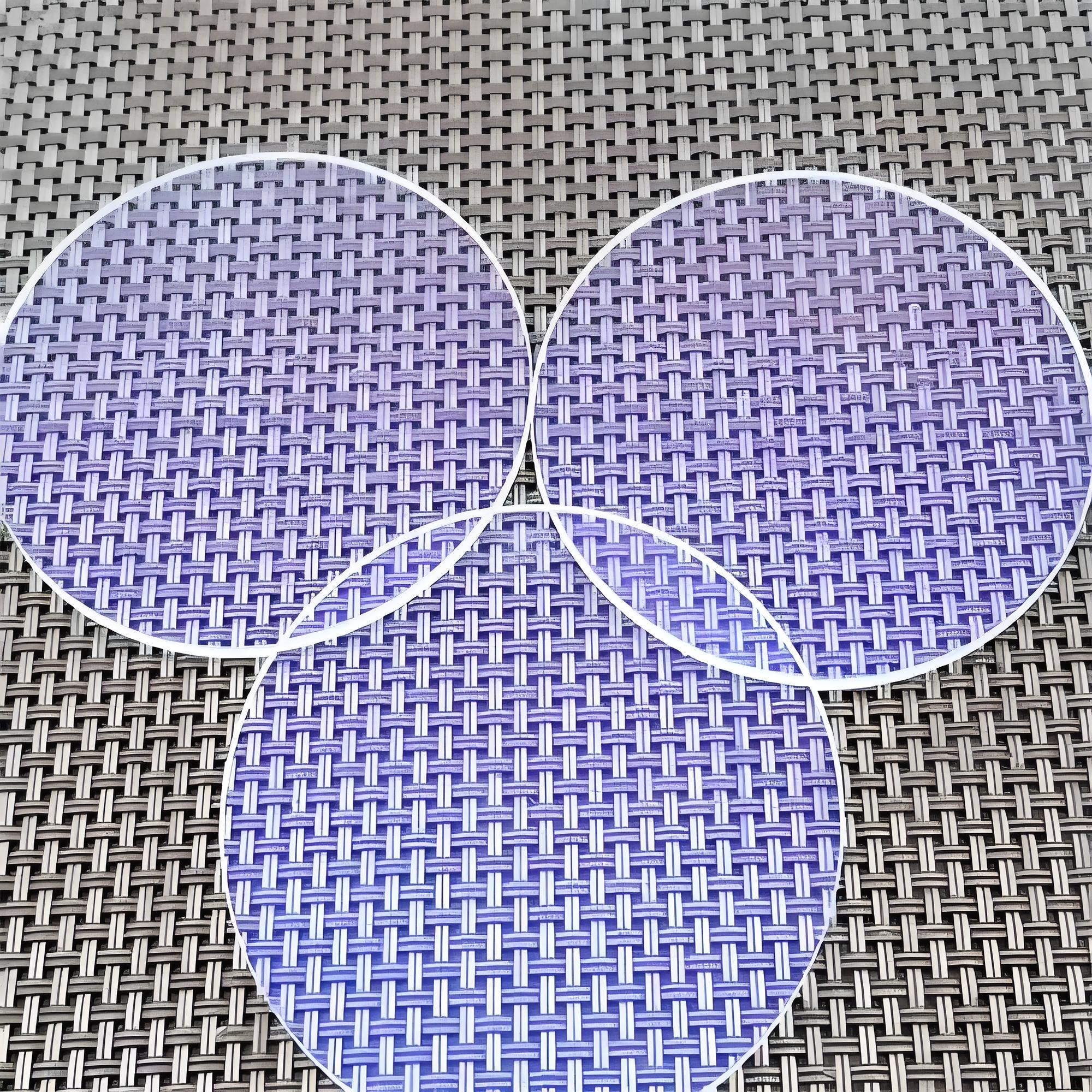

The circle tempered glass widely used in downlight, CCTV, etc. and the process is simple but quality is vary under different methods.

The process method depends on application, lighting normally use laser, shapping machine, and higher standard(edge treatment, tolerance, surface quality) we will use CNC to meet.

If there any other question, please recommend to contact us!

Introduction of tempered glass

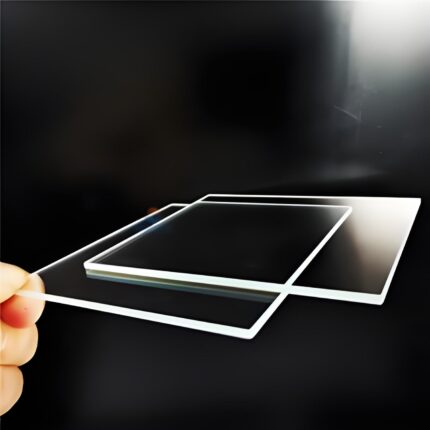

Tempered Glass Material

The circle tempered glass usually use soda lime float glass to be raw material for process, and the ultra clear(super white) is more widely use due to higher transmittance(91% above) and white(not green) from side view).

Different shapes and sizes of tempered glass can customize base on your requirements(drawings). After tempering, the circle glass has strong mechanical strength and safe to human.

When break, the glass will become into blunt glass fragments(small particles without sharp edge) to guarantee the safety.

Reference

– Soda lime glass: widely available, cheaper, and the working temperature up to 280 °C.

– Borosilicate glass: particularly suitable for aggressive environments (acids, alkalis, water vapor), working temperature up to 350 °C.

– Quartz glass: working temperature up to 1100 °C.

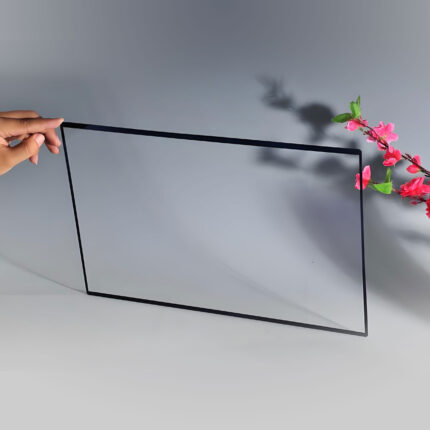

Surface treatment

Sandblasting: From industry, the sand option from #100 to #320(from rough to fine) depends on customer’s lighting effect requirement.

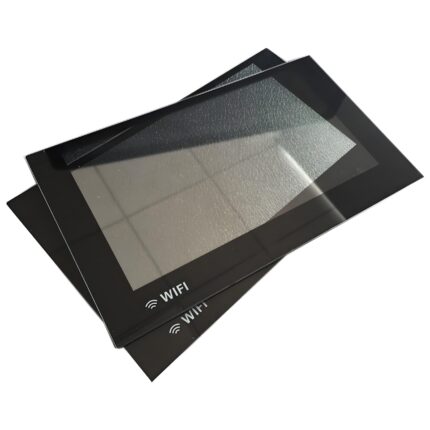

Printing: Low temperature ink(Stronger light block capability, can scratch out) and high temperature ink(weaker light block capability, can’t be scratched).

Customization size

Diameter(width/length) 10-420mm.

Thickness: 2-30mm (can be tempering) but 30-85mm (can not be tempering).

Tempered Glass Features

-The tempered glass can offer 4- 5 times stronger than ordinary anneal glass.

-In the event of breakage, it fractures safely into relatively small pieces with harmless dull edges.

-It can withstand a wide range of rapid temperature change.

Process methods

-CNC, it refers to high quality standard:

1.Precision tolerance ±0.05.

2.High surface quality: reduce defectives like scratch, dots, etc.

3.Even shape and edge(chamfer can be customized), the production cost relatively higher.

-Laser, the convenience allow the production speed much faster & cost lower.

Better tolerance ±0.02. But weaker chamfer compare to CNC(For lighting application, because it normally use hand chamfer instead of CNC to reduce cost)

Package

-PET film apply in double sides for high quality standard.

-Dustfree paper apply for lower cost option.

Weiman Tech can offer different customization services for tempered glass to satisfy with customers’ specific demand.