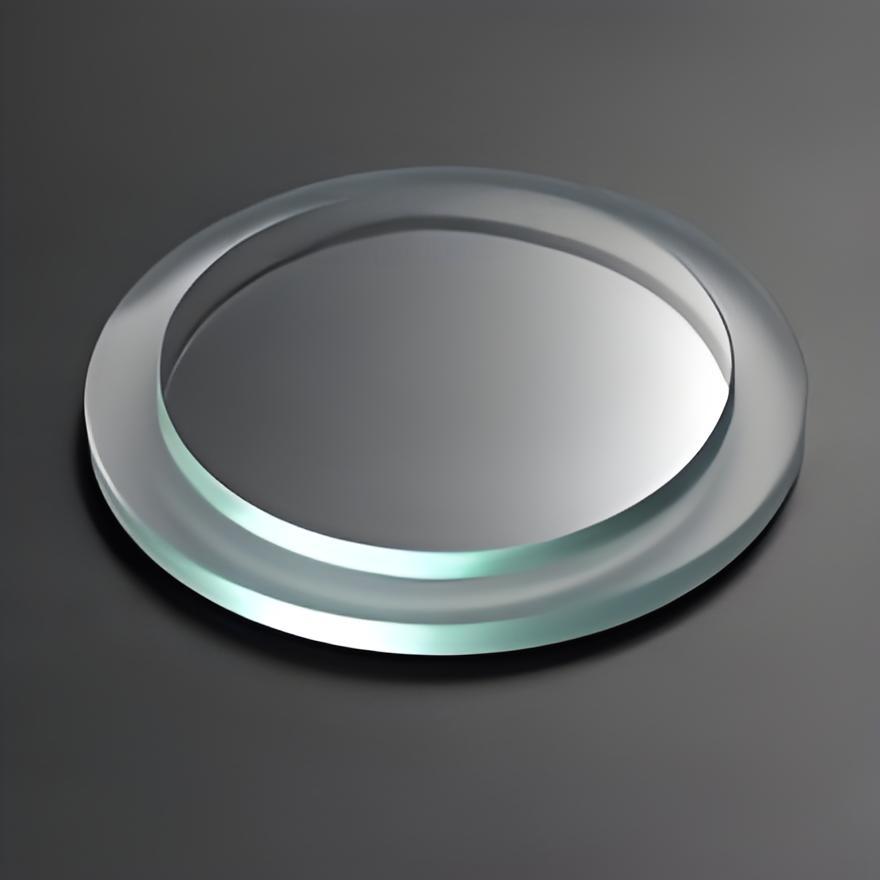

Industrial CCTV Sight Glass | Thermal Tempered Step Lens Cover

The sight glass is widely apply in lighting(burial lamp), household application(view window, like coffee machine) and other applications(camera like CCTV, bath etc).

The process method depends on application, lighting normally use shapping machine, and higher standard(edge treatment, tolerance, concentration) we will use CNC to meet.

Introduction of tempered ultra clear sight glass

Detail Reference(sight glass):

Sight Glass Material

The sight glass regually use sodalime float glass to be raw material for process, the ultra clear(super white) is more widely apply due to higher transmittance(91% above) and white(not green) from side view).

Different shapes and sizes of step glass we can custom base on your requirements(drawings). After tempering, the step glass has strong mechanical strength and safe to human.

When break, the glass will become into blunt glass fragments(small particles without sharp edge) guarantee the safety.

– Soda lime glass: widely available, cheaper, working temperature up to 280 °C.

– Borosilicate glass: particularly suitable for aggressive environments (acids, alkalis, water vapor), working temperature up to 350 °C.

– Quartz glass: working temperature up to 1100 °C.

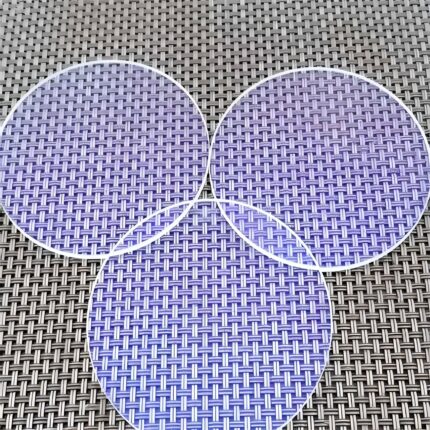

What’s the option of step glass shape

Round, square, rectangular, triangular, oblong.

Surface treatment

-Sandblasting, in market there are Sand #100~#320(rough ~fine) for selection.

To pursue more matt effect, rough sand will be better choice and find sand mainly focus on surface fine matt.

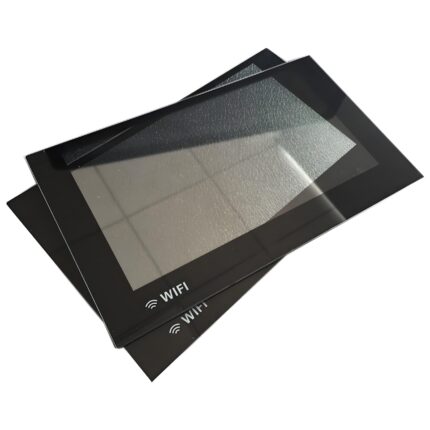

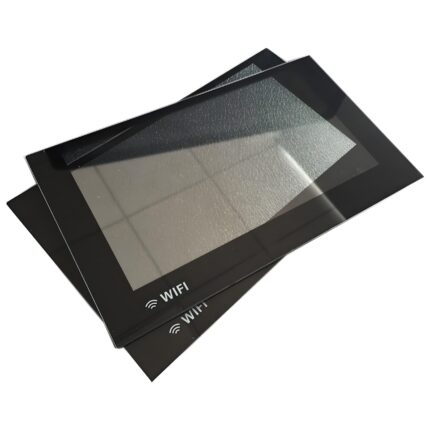

-Printing, regularlly high temperature(ceramic) ink is the first priority choice because of the ink’s anti scratch capability.

Customization size

Diameter(width/length) 10-420mm.

Thickness: 2-30mm (canbe tempered); 30-85mm (cannot be tempered)

Features

-4- 5 times stronger than ordinary annealed glass.

-In the event of breakage, it fractures safely into relatively small pieces with harmless dulled edges.

-It can withstand a wide range of rapid temperature changing.

Tempering Process

-Thermal tempering: To burial lamp, the tempering method is the more regular choice because:

It’s for outdoor purpose, frequent pressure bearing will request the glass’ full body hardness / IK level.

–Chemical tempering: To CCTV and other camera application, the transmittance / flatness will be the focus point.

After chemical tempering, the surface toughened(The level depends on different material and tempering time).

Production Process

1.CNC machine, this way is good for higher requirement on glass surface quality because it’s one time forming.

In this case, the concentric of 2 circles and even edge have better control.

2.Shaping machine, compare to CNC the advantage is the cost is lower but:

Tolerance weaker control than CNC.

Edge chamfer by hand(Then it depends on workers’ Proficiency level)