Electrodeposited Coating Anti-Reflective Glass

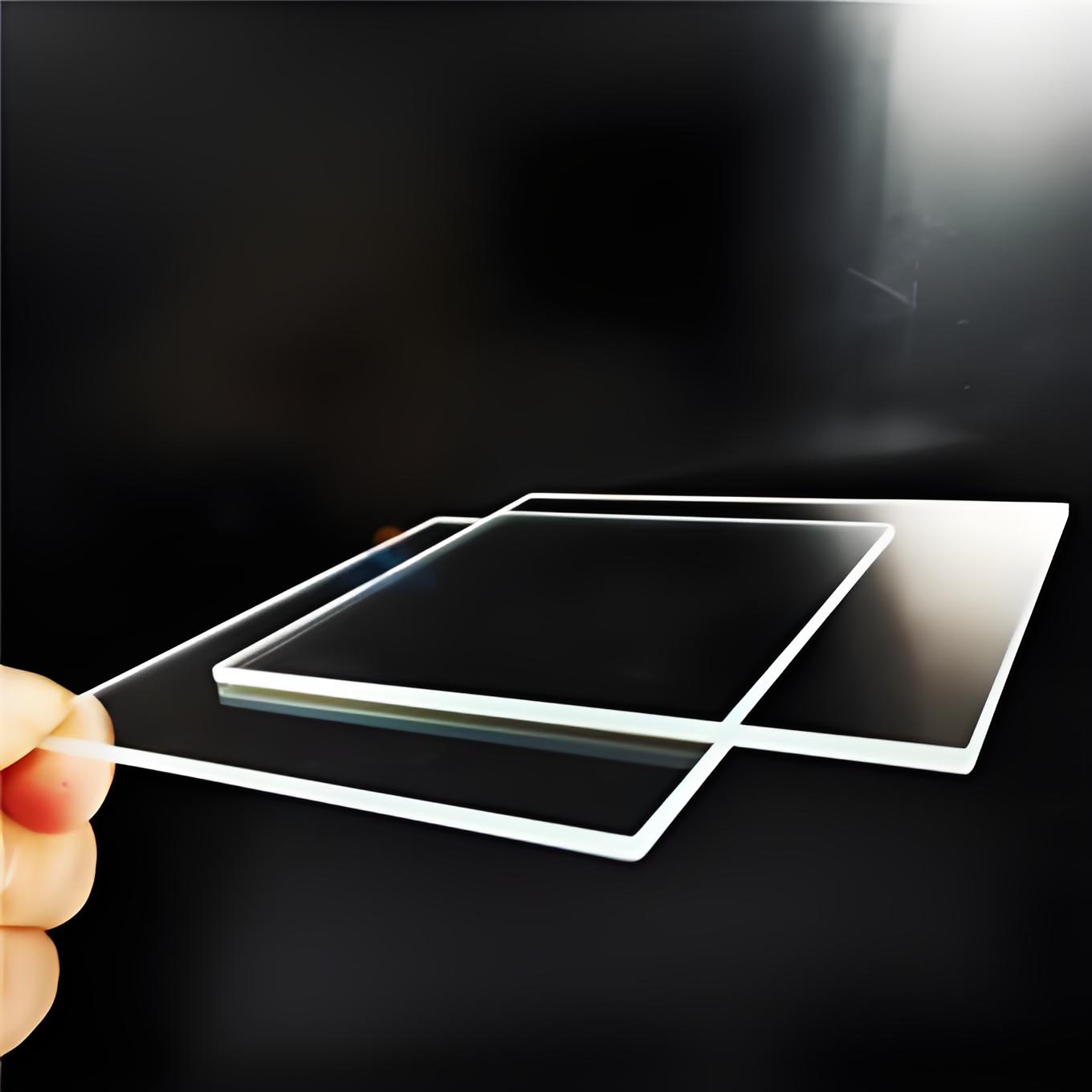

Electrodeposited Anti-Reflective Glass: Ultimate Clarity & Durability

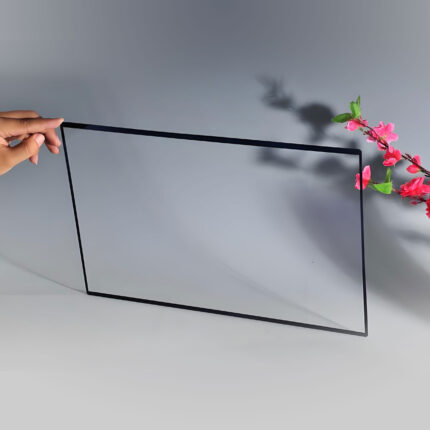

Our electrodeposited anti-reflective (AR) coating glass drastically eliminates glare and maximizes light transmission. Choose single-sided coating (96% transmission) for cost-effective glare reduction or premium double-sided coating (>98% transmission) for unparalleled clarity where color fidelity is critical. Unlike softer coatings, our electrodeposited ceramic-hard layer offers exceptional abrasion and chemical resistance, ensuring lasting performance in demanding applications like medical displays, museum exhibits, and industrial touchscreens.

The Clear Advantage: A Deep Dive into Electrodeposited Coating Anti-Reflective Glass

If you’ve ever been frustrated by glare on your smartphone in the sun, struggled to see a car display while driving, or wondered how high-end museum displays look so incredibly vivid, you’ve encountered the problem that anti-reflective coating glass solves. Among the various methods to create this glass, electrodeposition stands out for its unique blend of performance and durability. This isn’t just technical jargon; it’s a technology that fundamentally enhances how we interact with displays and optics every single day. Let’s break down exactly what it is, why it matters, and how the numbers stack up.

What is Electrodeposited AR Coating Glass? Beyond the Shine

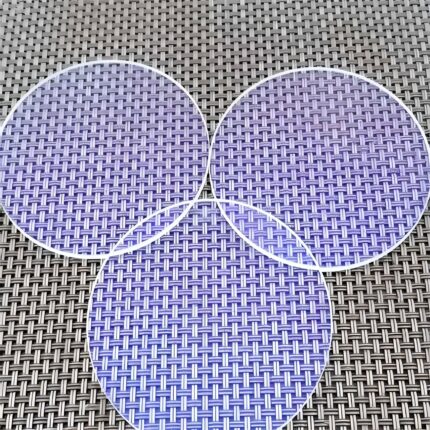

At its heart, electrodeposited AR coating glass is a high-quality glass substrate—often soda-lime or aluminosilicate—that has undergone a specific chemical process to drastically reduce surface reflection. The term “electrodeposition” might sound complex, but it’s akin to electroplating. Instead of happening in a high-tech vacuum chamber, this process takes place in a liquid bath.

The glass is immersed in a solution containing specific metal salts. When an electrical current is applied, it triggers a reaction that causes these metals to form a thin, incredibly strong, and uniform oxide layer on the glass surface. This layer is the magic behind the anti-reflective property. The real skill lies in precisely controlling this process to engineer the coating’s thickness and density, allowing it to target and cancel out specific wavelengths of light through wave interference. The result is a surface that seems to disappear, offering a view that’s noticeably clearer and sharper than untreated glass.

Single-Sided vs. Double-Sided Coating: A Practical Choice

One of the key decisions when specifying this type of glass is whether to coat one side or both. This isn’t just a matter of cost; it’s about the application’s specific needs.

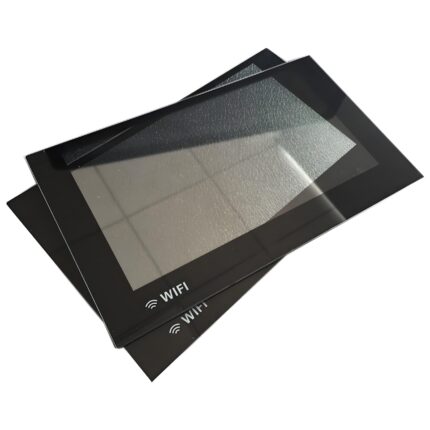

Single-Sided AR Coating

As the name implies, only one surface of the glass receives the coating. This is the go-to choice for situations where the primary goal is to eliminate a specific source of glare or reflection. A perfect example is the cover glass for an outdoor kiosk or an industrial control panel. The user is on one side, and the main light source (the sun or overhead lights) is also on that side. Coating just the exterior surface tackles that reflection head-on. It’s a cost-effective solution that solves the most immediate problem. The interior surface remains untreated, which is fine if it’s housed in a dark enclosure.

Double-Sided AR Coating

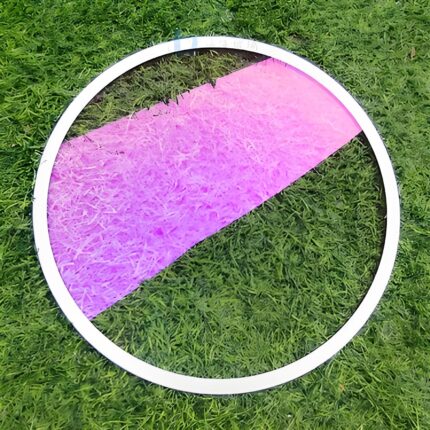

For the ultimate in optical performance, double-sided coating is the only way to go. Here, both the front and back surfaces are treated. Why does this matter? Even if you eliminate reflection from the front surface, light passing through the glass can still reflect off the interior surface and create secondary ghosts or haze, reducing overall contrast. By coating both sides, you virtually eliminate reflection from all angles. This is non-negotiable for applications like high-precision instruments, microscope lenses, protective glass for fine art, and any display where absolute clarity and color fidelity are paramount. The difference to the naked eye is staggering.

Seeing the Difference: A Data-Driven Comparison

It’s one thing to talk about performance; it’s another to see it in hard numbers. Light transmission is measured as a percentage of light that passes through the glass compared to the light that hits it. Here’s a breakdown of what you can typically expect:

Uncoated Clear Glass: A standard pane of clear glass might seem transparent, but it’s far from perfect. Each air-to-glass surface reflects about 4% of the incoming light. With two surfaces, that adds up to roughly 8% total reflection loss. This means the best transmission you can usually get from uncoated glass is about 91-92%. This lost light is what causes distracting reflections and diminishes the brightness and contrast of the display underneath.

Single-Sided AR Coated Glass: Applying a premium electrodeposited AR coating to one surface reduces the reflection on that side to less than 1.5%, and often as low as 1.0%. The other side remains at ~4%. This significantly improves the situation. You can expect the total light transmission to jump to approximately 95-96.5%. The reduction in glare on the coated side is immediately visible, making the screen much easier to read in bright conditions.

Double-Sided AR Coated Glass: This is where the technology truly shines. A high-quality electrodeposited coating can reduce reflectance on each surface to below 1.0%. With both surfaces optimized, the total reflection loss is minimized, pushing the total light transmission to an exceptional 98% or even higher. This near-perfect clarity means colors appear more saturated, blacks look deeper, and the image has a “no-glass” effect that is crucial for immersive experiences and critical viewing applications. The absence of ghost images and haze provides a level of clarity that feels like a direct view.

Why Electrodeposition Wins for Durability

A common weakness of some AR coatings, especially older vacuum-deposited ones, is that they can be soft and easily scratched or damaged by cleaning. Electrodeposited coatings have a massive advantage here. The process creates a hard, ceramic-like layer that is integral to the glass surface. This makes it exceptionally resistant to abrasion, chemicals, and environmental weathering. You can clean it repeatedly without worrying about degrading the anti-reflective properties, which is essential for products designed to last for years in demanding environments.

Real-World Applications: Where You’ll Find This Glass

This isn’t a lab-only curiosity. You interact with this technology more than you might think:

-

Retail & Museums: Protecting high-value prints and paintings without compromising the viewer’s experience.

-

Medical Displays: Ensuring surgeons can see every critical detail on a monitor without any reflection obscuring the image during a procedure.

-

Industrial HMIs: Making touchscreens readable on the factory floor under harsh lighting.

-

Advanced Automotive Displays: Dashboards and center consoles that remain clear and visible in all driving conditions.

-

High-End Appliances: Ovens and refrigerators with integrated displays that look sleek and are always readable.