Custom Double-Sided AR Glass | Ultra-Clear, High Transmission, Low Reflection Glass Panels

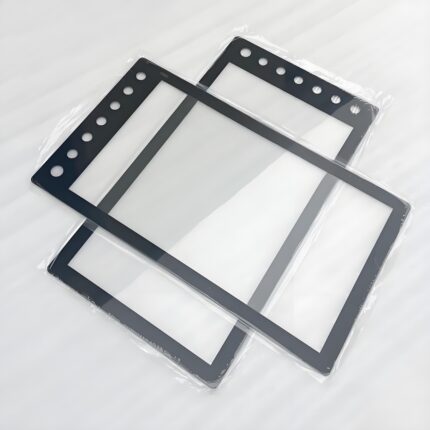

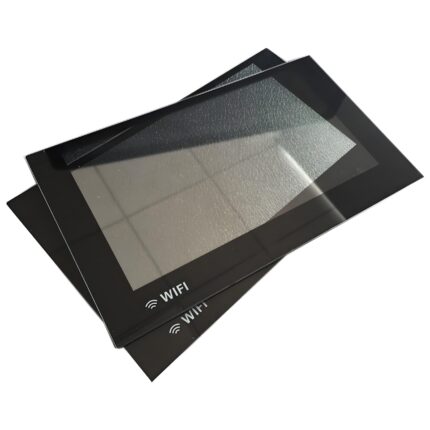

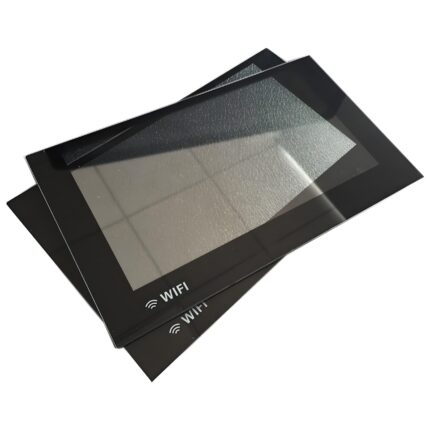

Custom Double-Sided AR Coated Glass

Achieve unparalleled clarity with our premium anti-reflective glass, engineered to deliver over 98.5% light transmission and reduce reflectance to below 1.5% per surface. Ideal for medical displays, high-end kiosks, automotive dashboards, and precision instruments, it eliminates glare while enhancing color vibrancy and contrast. Customizable in size, thickness, substrate, and coating specs (e.g., NIR/UV targeting). Combined with 7H hardness and chemical durability, it ensures reliability in demanding environments. Partner with us for tailored optical solutions.

Premium Optical Clarity Redefined with Our Custom Double-Sided AR Glass

Are you tired of battling frustrating glare and diminished clarity in your high-end displays or optical devices? Our custom-engineered Double-Sided Anti-Reflective (AR) Glass is the definitive solution. Meticulously crafted for applications where uncompromised optical performance is non-negotiable, this glass transforms user experience by delivering breathtaking image quality, vibrant color contrast, and unparalleled light transmission. We don’t just sell glass; we provide a critical optical component tailored to elevate your product from ordinary to exceptional. Whether you’re integrating it into a medical imaging display, a museum showcase kiosk, a sophisticated automotive dashboard, or a precision instrument, our AR glass ensures the content, not the reflection, remains the star of the show.

What is Double-Sided Anti-Reflective (AR) Glass?

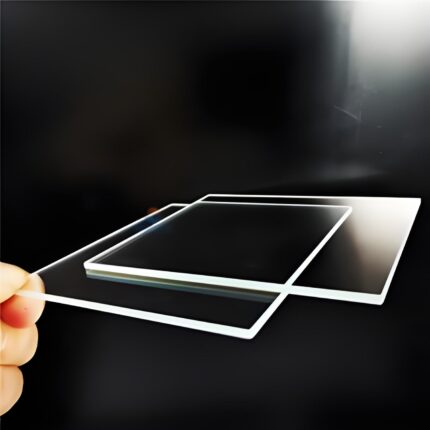

Unlike standard glass, which reflects a significant amount of incident light, our AR glass undergoes a specialized vacuum coating process. A series of precise, nano-scale optical layers are applied to both surfaces of ultra-clear substrate glass. These layers work on the principle of wave interference. By carefully controlling their thickness and refractive index, light waves reflecting off the top and bottom of the coatings are made to be out of phase with each other. This causes them to destructively interfere, effectively cancelling each other out and drastically reducing overall reflectivity. The result? Over 99% of the light passes directly through the glass to the viewer’s eye, eliminating distracting ghosts and hotspots.

Key Technical Specifications & Performance Data

Understanding the numbers is key to making an informed decision. Below is a detailed breakdown of the standard performance metrics we achieve with our advanced double-sided AR coating process.

Table: Standard Double-Sided AR Glass Performance Parameters

| Parameter / Property | Standard Value | Measurement Conditions / Notes |

|---|---|---|

| Average Reflectance | ≤ 1.5% | Per surface, measured at 550 nm wavelength. |

| Peak Reflectance | < 2.0% | Across the visible spectrum (380-780 nm). |

| Light Transmission | ≥ 98.5% | Measured at 550 nm wavelength. |

| Haze Value | < 0.5% | Ensuring true image integrity without diffusion. |

| Surface Hardness | ≥ 7H | Pencil hardness test for excellent scratch resistance. |

| Chemical Durability | High Resistance | Resists abrasion from cleaners and solvents. |

| Environmental Stability | Stable | Performs consistently across -30°C to +85°C. |

| Cleanroom Standard | Class 1000 | Manufactured in a controlled environment. |

Unmatched Benefits for Your demanding Applications

1. Crystal-Clear Visual Fidelity

Experience true-to-life imagery with our ultra-high transmission rates. By minimizing light loss, colors appear more saturated, blacks become deeper, and overall image sharpness is significantly enhanced. This is absolutely critical for applications like diagnostic medical displays, graphic design monitors, and high-resolution touch interfaces.

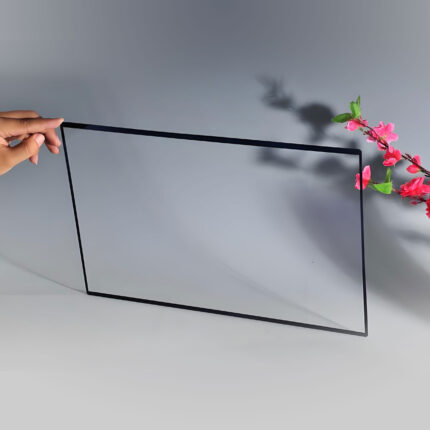

2. Virtually Eliminated Distracting Glare

Say goodbye to eye strain and frustrating reflections from overhead lighting or sunlight. Our AR coating ensures optimal readability and viewability in virtually any lighting condition, improving user interaction, safety, and satisfaction in environments from outdoor kiosks to bright operating rooms.

3. Enhanced Durability and Easy Maintenance

We understand that optical components must last. Our coatings are not only optically superior but are also hardened to resist scratching, abrasion, and chemical degradation from frequent cleaning. This ensures long-term performance and reduces the total cost of ownership.

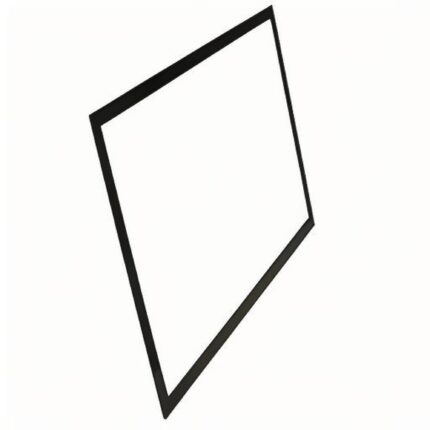

4. Fully Customizable to Your Exact Blueprint

Your project is unique, and your components should be too. We offer comprehensive customization options including:

-

Glass Substrate: Choice of soda-lime, aluminosilicate, or ultra-thin glass.

-

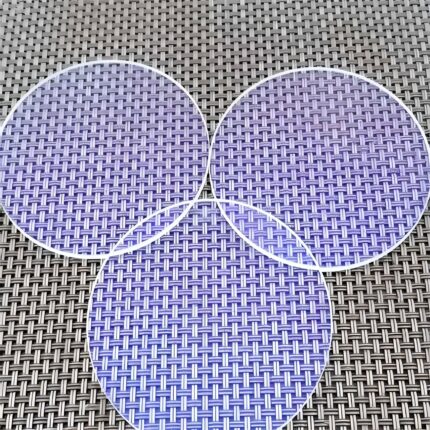

Size & Shape: Precision CNC cutting, drilling, and edge grinding to your exact dimensions and tolerances.

-

Thickness: From 0.55mm to 12mm and beyond.

-

Coating Specification: Tailored reflectance/transmission curves for specific wavelengths.

-

Additional Processing: Ability to combine with AG (Anti-Glare), AF (Anti-Fingerprint) coatings, or chemical strengthening.

-

Who Needs Double-Sided AR Glass? Our Target Industries

Our glass is the invisible engine behind clarity in a vast range of sectors. If your product has a display or an optical path, our AR glass can improve it.

-

Medical & Surgical: Diagnostic imaging displays (DICOM), surgical microscope lenses, dental cameras, analytical equipment.

-

Industrial & Automation: High-precision touchscreens for HMI, machine vision systems, inspection windows, scanner glasses.

-

Consumer Electronics: Premium smart home displays, high-end picture frames, virtual reality (VR) lenses, showcase kiosks.

-

Transportation: Aviation cockpit displays, automotive center consoles and instrument clusters, marine navigation systems.

-

Digital Signage & Retail: Interactive kiosks, museum exhibit displays, high-end retail presentation cases.

Why Partner With Us for Your AR Glass Needs?

Choosing us means more than just buying a component; it’s forging a partnership. Our technical sales team possesses deep expertise in optical materials and will work directly with your engineers to specify the perfect solution. Our state-of-the-art manufacturing facilities are equipped with advanced magnetron sputtering coating machines and rigorous QA inspection systems, ensuring every sheet of glass meets the highest standards. We are committed to providing competitive pricing, reliable lead times, and exceptional technical support from prototype to full-scale production.

Ready to see the difference true clarity makes? Contact our engineering team today for a confidential consultation and receive a personalized quotation tailored to your project’s specific needs.

-