Custom AG Display Strengthened Glass

Tired of glare ruining your display? Our custom AG strengthened glass eliminates reflections and fingerprints while providing superior durability. We chemically strengthen each piece to withstand impacts and scratches. Perfect for automotive displays, medical equipment, and industrial touchscreens. Available in various sizes, thicknesses, and haze levels to match your specific needs. Enhance readability and user experience in any lighting condition. Request a quote for your project today.

The Ultimate Guide to Custom AG Display Strengthened Glass

Introduction

Imagine using your tablet at the beach or trying to view your car’s navigation screen under the glaring afternoon sun. That frustrating glare and fingerprint-smudged surface are exactly what custom Anti-Glare (AG) strengthened glass solves. This specialized material has become the unsung hero behind comfortable viewing experiences in our daily technology.

AG display glass goes beyond being just a protective layer – it’s a sophisticated solution that enhances how we interact with screens. From retail kiosks to medical equipment, and from smartphones to industrial control panels, this material combines durability with optical excellence. The “custom” aspect is particularly crucial because every application has unique requirements for size, shape, and performance characteristics.

The marriage of anti-glare properties with mechanical strengthening creates a product that stands up to both visual and physical challenges. While standard glass might offer basic protection, custom AG strengthened glass delivers tailored performance that makes technology more usable and durable in real-world conditions. This article explores everything you need to know about this remarkable material.

What is AG Strengthened Glass?

AG strengthened glass is a dual-purpose material that combines two important properties: surface treatment to reduce reflections and mechanical enhancement to improve durability. The anti-glare aspect is achieved through either chemical etching or coating applications that create a microscopically rough surface. This roughness breaks up direct light reflections, diffusing light instead of creating mirror-like reflections that make screens difficult to read.

The strengthening process typically involves thermal tempering or chemical strengthening. Thermal tempering heats the glass to near melting point then rapidly cools it, creating compressive stresses on the surface that make it 4-5 times stronger than regular glass. Chemical strengthening involves ion exchange in a molten salt bath, creating a compression layer that provides exceptional strength and impact resistance without optical distortion.

What sets this material apart is how these two properties work together. The anti-glare treatment doesn’t compromise the structural integrity, and the strengthening process doesn’t diminish the optical benefits. The result is glass that not only makes screens easier to read in various lighting conditions but also withstands the drops, impacts, and daily wear that would destroy ordinary glass.

Key Benefits of Custom AG Glass

The advantages of custom AG strengthened glass extend far beyond basic screen protection. The most immediate benefit is the dramatic reduction in glare and reflections. Whether you’re using a device in bright sunlight or under harsh interior lighting, the screen remains readable without needing to cup your hands around it or search for a better viewing angle. This visual comfort reduces eye strain during extended use.

Durability is another significant advantage. The strengthening process creates glass that can withstand significant impact and pressure. This means devices survive accidental drops better, and screens resist the scratches that inevitably occur with daily use. For equipment that needs to last years in demanding environments, this durability translates to lower maintenance costs and fewer replacements.

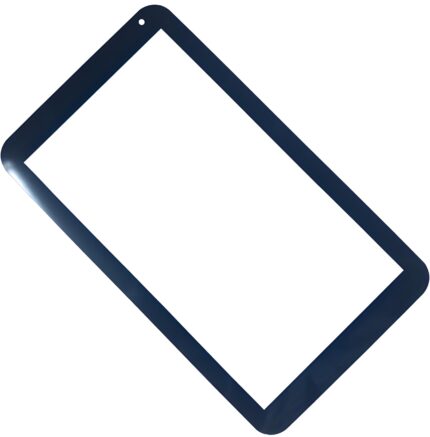

Customization unlocks additional benefits. The ability to specify exact dimensions, edge work, hole patterns, and coating uniformity means the glass integrates perfectly with your product design. You can choose the precise level of haze that balances glare reduction with image clarity for your specific application. This tailored approach ensures optimal performance rather than settling for a one-size-fits-all solution.

Applications Across Industries

Custom AG strengthened glass serves critical functions across diverse sectors. In the medical field, it’s used in diagnostic equipment displays where clarity can impact decision-making. Hospitals need glass that can withstand frequent cleaning with harsh disinfectants while maintaining clear visibility of patient vital signs and imaging results.

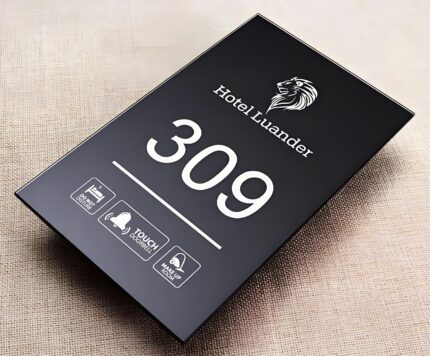

The automotive industry relies on AG glass for dashboard displays and center console screens. These applications require materials that remain readable in direct sunlight while surviving temperature extremes and vibration. The anti-fingerprint properties are particularly valuable in vehicles where multiple users interact with the same screens.

Retail and hospitality environments utilize custom AG glass for interactive kiosks, point-of-sale systems, and digital signage. These applications benefit from reduced reflections in brightly lit stores while standing up to constant public use. The durability ensures these investments continue performing despite the inevitable bumps and scratches of high-traffic environments.

Industrial settings represent another important application. Manufacturing control panels, measurement equipment, and warehouse management systems all use displays that must remain readable in various lighting conditions while resisting the knocks and spills of busy work environments.

The Customization Process

Creating custom AG strengthened glass begins with understanding the specific application requirements. The process starts with discussing environmental factors like lighting conditions, expected usage patterns, and durability needs. This consultation helps determine the appropriate glass thickness, which typically ranges from 0.5mm to 3mm depending on the application.

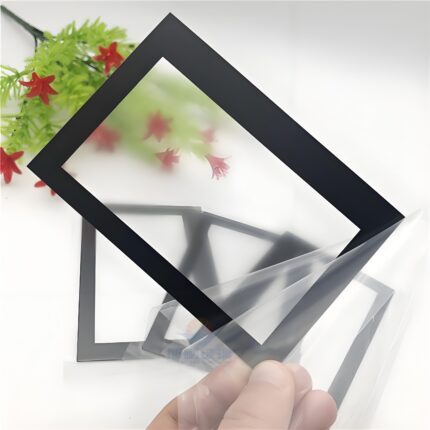

The manufacturing process involves several precise steps. First, glass is cut to exact specifications using computer-controlled cutting tools that ensure accuracy within tight tolerances. Edge grinding follows, creating smooth, safe edges that are either polished for a finished look or left with a ground finish for industrial applications.

Next comes the strengthening process. For chemical strengthening, glass undergoes ion exchange in a salt bath at approximately 400°C. This creates a deep compression layer that provides exceptional strength. The anti-glare treatment is then applied through either etching or coating methods. Etching creates a permanent surface modification, while coating applications allow for different levels of haze control.

Quality control is integral throughout the process. Measurements verify dimensional accuracy, optical tests ensure proper light transmission and haze levels, and strength testing confirms durability standards are met. This comprehensive approach guarantees each piece performs as expected in its intended application.

Considerations for Implementation

Several important factors influence the success of custom AG glass implementation. The desired haze level requires careful consideration – typically measured as a percentage, with higher values providing more glare reduction but potentially slightly reducing image sharpness. Most applications use haze levels between 5% and 25%, with the optimal point depending on specific use cases.

Environmental durability must match the application requirements. For outdoor use or chemically harsh environments, additional surface treatments may be necessary. Similarly, the choice between chemical strengthening and thermal tempering depends on the required strength characteristics and dimensional constraints.

Integration with touch functionality is another key consideration. AG glass works well with both capacitive and resistive touch technologies, but may require specific surface resistivity values or additional coatings to ensure proper touch sensitivity. The anti-glare properties must be balanced with maintaining adequate touch response.

Cost factors include not just the per-unit price but the total cost of ownership. While custom AG glass may have a higher initial cost than standard solutions, the reduced replacement frequency and better user experience often provide significant long-term value. Minimum order quantities and lead times also factor into planning decisions.

Future Developments

The future of custom AG strengthened glass points toward increasingly sophisticated solutions. Emerging technologies include self-healing coatings that repair minor scratches automatically, and adaptive glare reduction that adjusts based on ambient light conditions. These advancements could further extend product lifespans and improve user experiences.

Sustainability is becoming increasingly important. Manufacturers are developing more environmentally friendly production methods and exploring recyclable alternatives without compromising performance. The industry is also moving toward more efficient manufacturing processes that reduce energy consumption and waste.

Integration with other technologies represents another exciting direction. We’re seeing developments that combine AG properties with anti-microbial coatings for medical applications, and embedded sensors that turn the glass itself into an input device. These innovations will continue expanding the possibilities of what protected displays can do.

As display technology evolves with foldable screens and new form factors, custom AG glass will adapt to provide protection and optical enhancement for these new designs. The constant innovation ensures this material will continue playing a vital role in how we interact with technology in our daily lives.

Conclusion

Custom AG strengthened glass represents the perfect marriage of form and function for modern display applications. By reducing glare while providing exceptional durability, it solves two of the biggest challenges in display technology. The customization capabilities ensure that each implementation delivers optimal performance for its specific use case.

From medical equipment to automotive displays, retail kiosks to industrial controls, this material enhances both the usability and longevity of devices we depend on daily. The careful manufacturing process and quality control ensure reliable performance that stands up to real-world conditions.

As technology continues to evolve, custom AG glass will adapt to meet new challenges and opportunities. For anyone designing devices with displays, understanding and utilizing this material can make the difference between a good product and a great one. The investment in quality AG glass pays dividends in user satisfaction and product reliability for years to come.