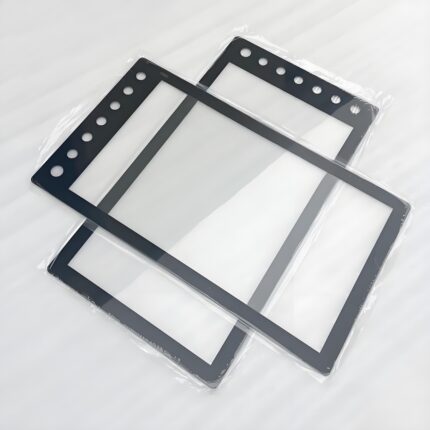

Anti-Fingerprint Coatings for Custom Cover Glass

Keep your displays pristine. Our Anti-Fingerprint coating on custom cover glass repels oils and smudges, making screens easy to clean and maintaining perfect clarity. We offer both spray and vacuum plating methods. Choose cost-effective spray coating for solid performance or ultra-durable vacuum plating for premium, long-lasting protection. We’ll help you select the right AF solution for your budget and product needs. Get a superior user experience and a flawless finish.

Anti-Fingerprint Coatings: A Guide for Custom Cover Glass

In the world of touchscreens and display panels, clarity is everything. Smudges, oils, and fingerprints from daily use can severely degrade the user experience, making screens difficult to read and unappealing to interact with. This is where Anti-Fingerprint (AF) coatings come in. For cover glass manufacturers and product designers, choosing the right type of AF coating—spraying or plating—is a critical decision that impacts cost, durability, and performance. Understanding the difference is key to selecting the best solution for your product.

What is an Anti-Fingerprint (AF) Coating?

An Anti-Fingerprint coating is a thin, transparent oleophobic (“oil-fearing”) layer applied to the surface of cover glass. Its primary function is to repel oils and moisture from skin contact, causing them to bead up rather than spread out into a visible smudge. This makes screens dramatically easier to clean with a simple wipe and maintains optical clarity. The coating works by significantly reducing the surface energy of the glass, creating a slick, smooth barrier that fingerprints struggle to adhere to. Beyond aesthetics, AF coatings also help protect the glass from minor abrasions and can enhance the overall feel of a premium device.

AF Coating Application: Spraying vs. Plating

The two predominant methods for applying AF coatings are spraying and plating (a term often used for vacuum deposition). Each technique has distinct processes, advantages, and drawbacks.

Spray Coating: The Accessible Method

Spray coating is a wet chemical process where the AF solution is atomized and sprayed onto the glass surface. The coated glass is then typically cured using heat to solidify the layer.

Effects and Performance:

Sprayed coatings are effective and provide a good level of oleophobicity. They are a reliable choice for many consumer applications. However, the coating thickness can be less uniform, especially on complex 3D shapes, which might lead to slight variations in performance or a visible “orange peel” effect under harsh lighting. The durability of sprayed coatings is generally lower; they are more susceptible to wear from repeated cleaning and abrasion over time.

Cost Implications:

This is where spraying shines. The equipment required for spray coating is significantly less expensive than vacuum deposition chambers. The process is faster to set up and has lower operational costs, making it incredibly cost-effective for high-volume, price-sensitive projects. It also allows for easier processing of larger or uniquely shaped glass parts.

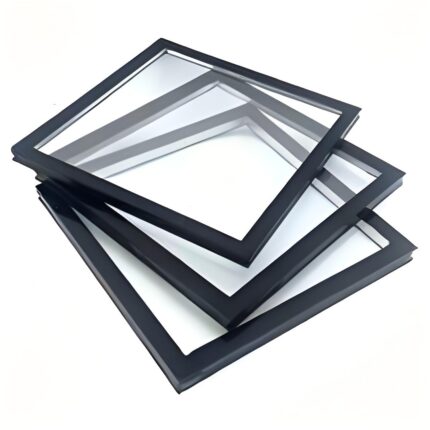

Plating (Vacuum Deposition): The Premium Performer

Plating, more accurately referred to as vacuum deposition, is a dry process. The glass is placed inside a sealed vacuum chamber. The AF coating material is then vaporized and condenses onto the glass surface in an extremely thin, perfectly even layer.

Effects and Performance:

Vacuum deposition is the superior technical solution. It creates an exceptionally uniform coating with unmatched consistency across the entire surface of the glass, even on edges. This results in optimal optical clarity with no risk of texture or distortion. The bonded layer is also far more durable, resistant to chemical cleaning agents, and can withstand extensive abrasion, often lasting the entire lifetime of the device.

Cost Implications:

This performance comes at a price. The vacuum deposition equipment represents a massive capital investment. The process is slower, requires meticulous chamber cleaning, and has higher energy consumption. Consequently, vacuum plating is a more expensive process per unit. It is typically reserved for high-end applications where top-tier performance and durability are non-negotiable.

Choosing the Right AF Coating for Your Application

The choice between spraying and plating isn’t about which is better, but which is better for your product.

-

For consumer electronics like budget to mid-range smartphones, tablets, and appliances where cost is a major driver, spray coating offers an excellent balance of performance and affordability.

-

For premium and flagship devices (high-end smartphones, luxury watches), medical equipment that requires frequent sterilization, industrial touchscreens subjected to harsh cleaning chemicals, or automotive displays, the investment in vacuum plating is justified. Its superior durability and perfect clarity protect the product’s premium feel and functionality.

The Weiman Tech Advantage

At Weiman Tech, we don’t believe in a one-size-fits-all approach. We offer both spray and vacuum deposition AF coating services. Our engineering team works directly with clients to understand their product’s requirements, target market, and cost targets. We then recommend the most appropriate AF solution—whether it’s the cost-efficiency of spraying or the elite performance of plating—ensuring you get the right protection for your project without overspending. This consultative partnership ensures your cover glass looks pristine, feels premium, and performs flawlessly for its intended lifespan.