Advanced Acid Etching Methods for High-Performance Electronic Glass

Advanced Acid Etching for Electronic Glass

Our precision acid etching technology enables ultra-fine patterning and surface structuring of high-performance electronic glass for demanding applications. Utilizing optimized chemical formulations and controlled process parameters, we achieve:

-

Sub-micron feature resolution (<0.5µm)

-

Superior surface quality (Ra <10nm)

-

High aspect ratio structures (up to 20:1)

-

Material-specific etching profiles (fused silica, borosilicate, aluminosilicate)

Ideal for:

✓ Semiconductor interposers & photomasks

✓ Advanced display components

✓ MEMS/optical device fabrication

Key advantages:

• Batch-to-batch consistency with automated process control

• Damage-free etching preserving glass strength

• Custom solutions for specialty glass compositions

Advanced Acid Etching Methods for High-Performance Electronic Glass

1. Introduction to Precision Glass Etching

In the rapidly evolving electronics industry, manufacturers increasingly rely on acid etching to produce ultra-thin, high-performance glass components. Unlike mechanical cutting or laser ablation, chemical etching enables micron-level precision without inducing microcracks or thermal stress. This white paper examines state-of-the-art acid etching methodologies specifically developed for electronic-grade glass, including their operational principles, advantages over alternative techniques, and implementation in real-world production environments.

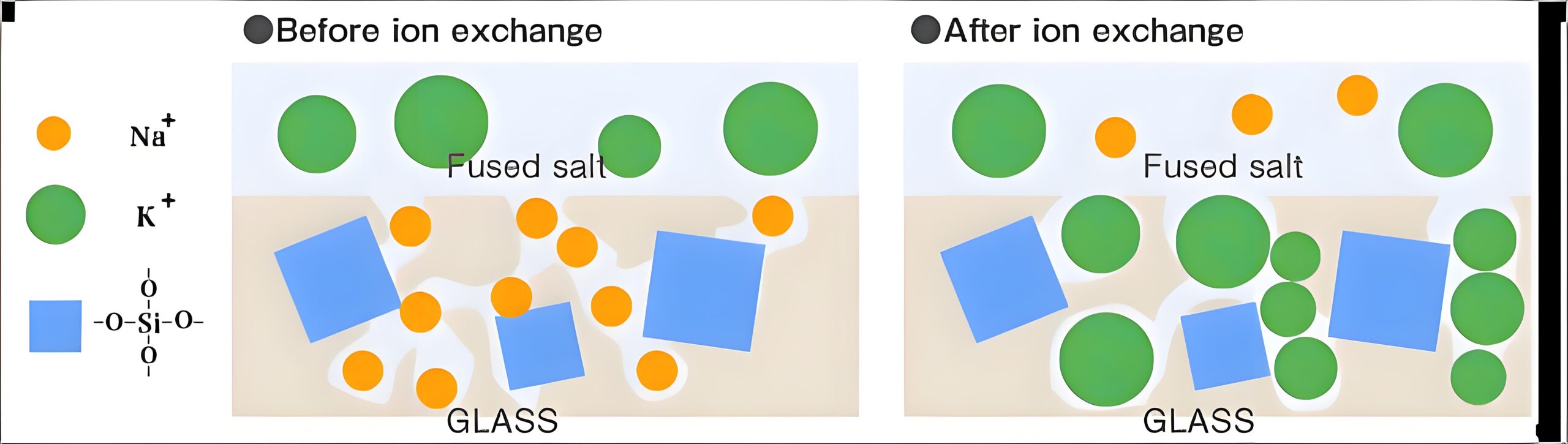

Chemical strengthened

2. Critical Applications in Modern Electronics

2.1 Next-Generation Semiconductor Devices

Leading semiconductor fabs utilize acid-etched glass for:

-

Extreme ultraviolet (EUV) photomask substrates requiring <5nm line edge roughness

-

Through-glass vias (TGVs) in 2.5D/3D IC packaging with aspect ratios exceeding 10:1

-

Wafer-level optics for computational imaging sensors

2.2 Advanced Display Systems

Recent breakthroughs in display tech demand novel etching approaches:

-

Microfluidic cooling channels etched into ultra-thin cover glass for augmented reality (AR) waveguides

-

Anti-glare surface texturing with controlled 20-50nm roughness for automotive HUDs

-

Flexible hybrid electronics (FHE) using chemically thinned borosilicate substrates

2.3 Emerging MEMS and Photonic Devices

Cutting-edge applications demonstrate etching’s versatility:

-

Glass interposers with 1µm precision cavities for quantum dot placement

-

Integrated photonic circuits featuring etched total internal reflection (TIR) mirrors

-

Lab-on-chip systems incorporating 3D microfluidic networks

3. Cutting-Edge Etching Methodologies

3.1 Advanced Wet Etching Techniques

Modern wet benches now incorporate:

-

Temperature-stabilized HF/HCl blends (±0.1°C control) for consistent 150nm/min etch rates

-

Surfactant-modified etchants reducing surface tension for uniform trench profiles

-

Closed-loop chemical monitoring with ion-selective electrodes maintaining bath stability

3.2 Dry Etching Innovations

Plasma-based systems achieve unprecedented results:

-

Cryogenic ICP-RIE at -120°C enables near-vertical 85° sidewalls in fused silica

-

Pulsed-gas etching minimizes microloading effects across 300mm wafers

-

Atomic layer etching (ALE) for sub-nanometer material removal control

3.3 Hybrid Processing Approaches

Combination techniques address complex requirements:

-

Laser-assisted wet etching creates 25µm deep features with <0.5µm placement accuracy

-

Electrochemically enhanced etching for selective material removal in multi-layer stacks

-

Ultrasonic agitation improving etchant penetration in high-aspect-ratio structures

4. Process Optimization Strategies

4.1 Material-Specific Etch Protocols

Tailored solutions for common electronic glasses:

| Glass Type | Preferred Etchant | Etch Rate (µm/min) | Surface Finish (Ra) |

|---|---|---|---|

| Fused Silica | BHF (7:1 NH4F:HF) | 0.8-1.2 | <5nm |

| Borosilicate | HF/HNO3 (1:3) | 2.5-3.5 | 10-15nm |

| Aluminosilicate | HF/H2SO4 (1:5) | 1.8-2.2 | <8nm |

4.2 Masking Technology Advancements

Comparative analysis of patterning methods:

-

Hard masks: 500nm LPCVD SiN provides >100:1 selectivity in deep etching

-

Photoresists: New chemically amplified resists withstand HF vapors for 4+ hours

-

Sacrificial layers: Temporary polymer coatings enable undercut control within ±2%

4.3 Environmental Controls

Critical parameters for production-scale etching:

-

Cleanroom Class 100 environment prevents particulate contamination

-

Dynamic exhaust systems maintain HF concentrations below 0.1ppm

-

Automated chemical titration compensates for etchant depletion

5. Quality Verification Methodologies

5.1 Dimensional Metrology

Advanced characterization tools:

-

X-ray computed tomography for 3D reconstruction of internal features

-

Coherence scanning interferometry measures depth with 0.1nm resolution

-

In-line SEM inspection with AI-based defect classification

5.2 Mechanical Testing

Post-etch validation procedures:

-

Biaxial flexure testing confirms strength retention >95% of pristine glass

-

Hermeticity testing via helium leak detection (<10^-9 mbar·L/s)

-

Thermal cycling (-55°C to 125°C) verifies microcrack resistance

6. Future Directions and Innovations

6.1 Sustainable Manufacturing

Industry initiatives addressing environmental concerns:

-

HF recycling systems achieving >90% acid recovery

-

Biodegradable chelating agents replacing EDTA in etch baths

-

Dry etching alternatives using fluorine-free precursors

6.2 Smart Process Integration

Industry 4.0 implementations:

-

Digital twin simulations predicting etch profiles with 98% accuracy

-

Adaptive neural network control dynamically adjusting process parameters

-

Blockchain-based chemical tracking for full material traceability

6.3 Novel Material Systems

Emerging glass compositions requiring specialized etching:

-

Chalcogenide glasses for mid-IR photonics

-

Phase-change memory glasses with selective elemental removal

-

Self-healing glass requiring non-damaging etch chemistries

Technical Advantages of Our Etching Solutions

-

Proprietary chemistry formulations certified for ISO 14644-1 Class 5 cleanrooms

-

In-house developed metrology capable of measuring 10nm features

-

24/7 remote process monitoring with real-time expert support