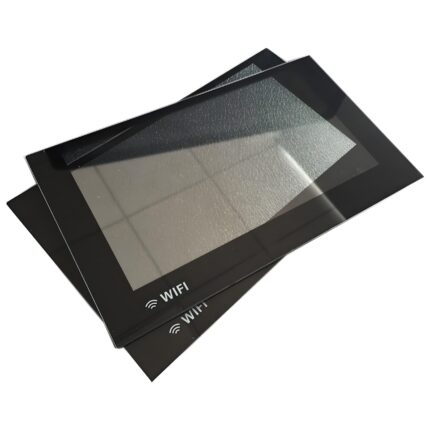

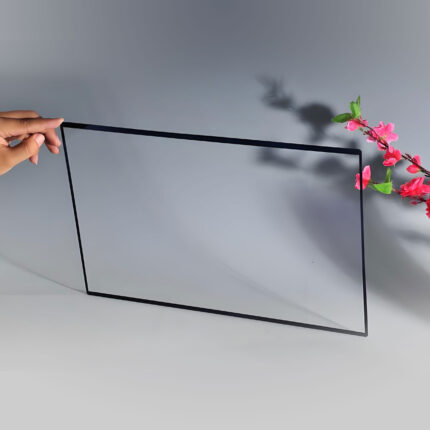

AR Electronic Cover Glass | Anti-Reflective, Anti-Smudge Coated Glass for Displays & Touchscreens

See the Difference: Unleash True Display Performance with AR Electronic Cover Glass

Let’s be honest—what’s the point of investing in a stunning high-resolution display if users are just going to see their own reflection? Glare and fingerprints are the arch-nemeses of clarity, plaguing everything from a surgeon’s diagnostic monitor to a customer-facing kiosk. That’s where our specialized AR Electronic Cover Glass comes in. We’ve engineered this glass not just as a protective layer, but as a performance-enhancing optical component. It’s the secret weapon for product designers who refuse to compromise on visual fidelity. By seamlessly integrating advanced anti-reflective and often oleophobic coatings, we ensure your display content is the undisputed focal point, crystal clear and free from distracting reflections or messy smudges. This isn’t just glass; it’s the window to a superior user experience.

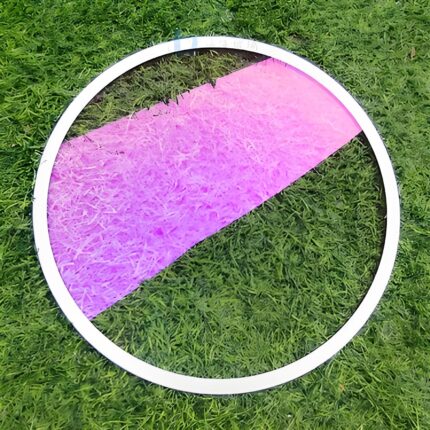

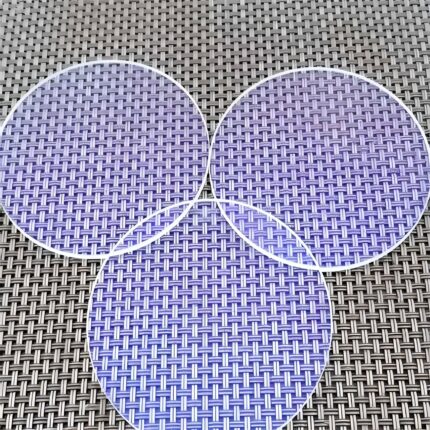

How Does Anti-Reflective (AR) Cover Glass Actually Work?

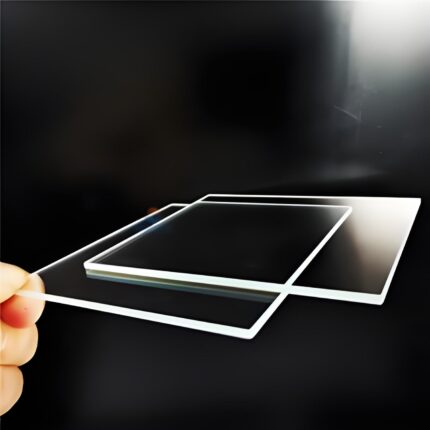

The science behind it is as fascinating as the results. Standard glass reflects about 8% of the light that hits it—4% from each surface. Our AR coating is applied using a precise magnetron sputtering process in a vacuum chamber. This process deposits multiple, nano-scale layers of metal oxides onto the ultra-clear glass substrate. Each layer is engineered to a specific thickness to target particular wavelengths of light.

Here’s the cool part: these layers cause light waves to interfere with each other. The light reflecting off the top of the coating and the light reflecting off the glass surface are forced out of phase. Essentially, they cancel each other out (destructive interference), dramatically reducing the overall reflectivity. The majority of the light is then transmitted directly through the glass, resulting in a brighter, sharper, and more vibrant image with virtually no ghosting.

Technical Performance Data: By the Numbers

We know engineers and procurement teams need hard data. Here’s a detailed table outlining the key performance metrics of our standard AR Electronic Cover Glass.

Table 1: Standard Performance Parameters for AR Electronic Cover Glass

| Parameter / Property | Standard Performance Value | Test Method / Notes |

|---|---|---|

| Surface Reflectance | ≤ 1.5% (per side) | Measured at 550 nm wavelength. Can be customized lower. |

| Light Transmission | ≥ 93.5% | Measured at 550 nm wavelength. Rejects IR/UV if specified. |

| Haze Value | < 0.8% | Ensures no image distortion or cloudiness. |

| Fingerprint Resistance (Oil Contact Angle) | ≥ 110° | Oleophobic coating makes smudges easy to wipe away. |

| Surface Hardness | ≥ 7H | Pencil hardness test for excellent scratch resistance. |

| Chemical Resistance | High | Resists damage from common alcohols and cleaning solvents. |

| Abrasion Resistance | > 1,000 cycles | Steel wool (#0000) test under specified load with minimal change. |

| Environmental Stability | Stable | Performance maintained from -40°C to +85°C. |

| Substrate Options | Soda-lime, Aluminosilicate | Various thicknesses from 0.5mm to 3.0mm available. |

Why This Glass is a Game-Changer for Your Product

1. Unmatched Optical Clarity and Color Fidelity

This is the core benefit. By slashing reflectivity and boosting transmission, the display underneath appears significantly brighter and more legible, even under challenging lighting conditions. Colors pop with greater saturation and contrast, and blacks appear truly black. This is absolutely critical for applications where color accuracy and detail are paramount.

2. Enhanced User Experience and Readability

A screen free from glare is a screen that people can actually use. Whether it’s a customer struggling to see an outdoor ATM display or a factory worker interacting with an HMI panel under bright lights, our AR glass reduces eye strain and ensures seamless interaction. The added oleophobic coating means fingerprints are less noticeable and far easier to clean, maintaining a pristine appearance with minimal maintenance.

3. Superior Durability for Demanding Environments

We get it—cover glass takes a beating. That’s why our product is built to last. The hard coatings provide exceptional resistance to scratches from daily use and cleaning abrasion. The high chemical durability means it won’t degrade when exposed to harsh cleaners or solvents common in medical and industrial settings. You get the optical performance of a premium component with the ruggedness the real world demands.

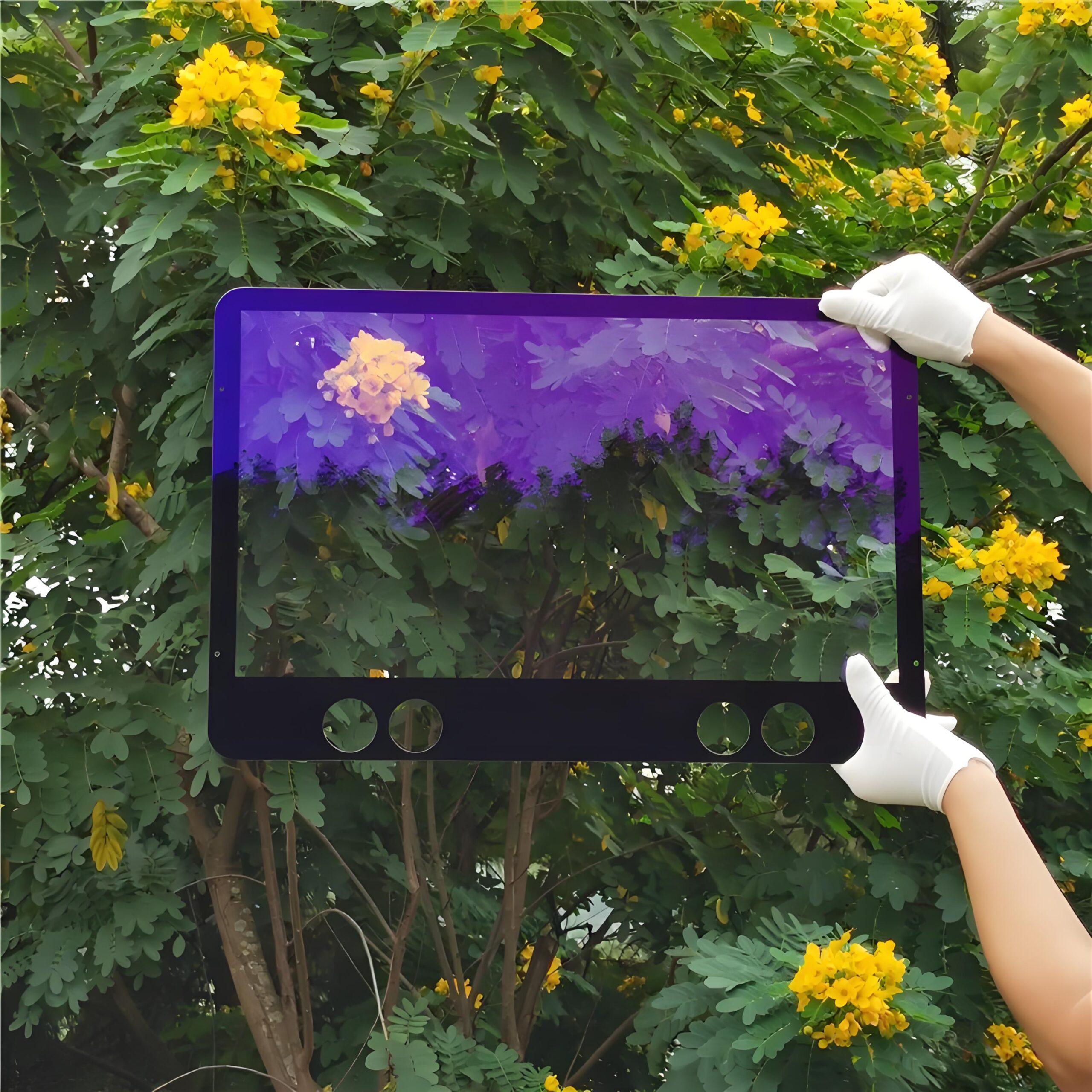

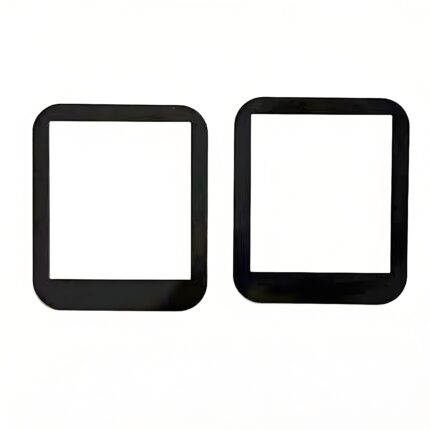

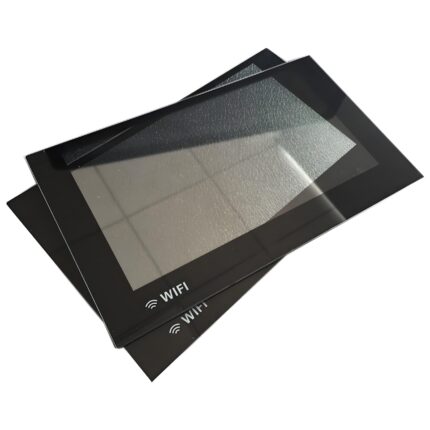

4. Total Customization and Integration

Your design isn’t off-the-shelf, and your cover glass shouldn’t be either. We offer extensive customization to perfectly integrate with your product:

-

Precision Cutting: CNC machined to your exact size, shape, and hole-cut specifications.

-

Edge Work: Polished, seamed, or chamfered edges for aesthetics and safety.

-

Additional Treatments: We can combine the AR coating with other functionalities like Anti-Glare (AG) etching for diffuse reflection or Chemical Strengthening for enhanced impact resistance.

-

Coating Tuning: Optimize the coating spectrum for specific applications (e.g., NIR transmission for fingerprint sensors).

-

Ideal Applications Across Industries

Where can you use it? The answer is nearly anywhere there’s a display.

-

Medical Technology: Diagnostic imaging monitors (DICOM compliance), surgical displays, patient monitoring systems, dental equipment.

-

Industrial Automation: Human-Machine Interface (HMI) panels, industrial touchscreens, measurement device readouts, factory floor kiosks.

-

Retail & Hospitality: Point-of-Sale (POS) systems, interactive informational kiosks, digital menu boards, self-service check-in terminals.

-

Transportation: Automotive center console displays, aviation cockpit screens, marine navigation equipment.

-

Consumer & Professional Electronics: High-end smart home controllers, gaming monitors, photography equipment displays.

-

Our Commitment: Your Technical Partner

We don’t just supply glass; we provide solutions. Our engineering team works directly with you to understand your challenges and recommend the optimal material and coating stack. Our production is backed by rigorous quality control, including spectral analysis, durability tests, and cleanroom manufacturing to ensure every batch meets spec. From prototype to mass production, we are committed to supporting your timeline and quality requirements.

Ready to eliminate glare and elevate your product? Contact us today to discuss your specific application and request samples. Let’s see what we can build together.

-