Ultra Thin Glass Electronic Cover Solutions for Modern Devices

Ultra Thin Glass Electronic Cover Glass Solutions for Modern Devices

Today’s cutting-edge devices demand cover glass that combines extreme thinness with uncompromising durability. Advanced chemically strengthened aluminosilicate formulations now deliver:

-

0.3-0.7mm thickness without sacrificing impact resistance

-

92%+ light transmission for crystal-clear visuals

-

800+ MPa surface compression for everyday durability

These ultra-thin solutions enable revolutionary designs in smartphones (edge-to-edge displays), wearables (curved surfaces), and foldables (200,000+ bend cycles). Manufacturers achieve this through precision down-draw processes and advanced laser machining, maintaining strict ±0.03mm thickness tolerances while incorporating optional anti-reflective, anti-fingerprint, and anti-microbial coatings.

Ultra Thin Glass Electronic Cover: The Future of Device Protection

Breaking Through the Limits of Thinness

Modern electronics manufacturers face an impossible challenge: create cover glass that’s simultaneously thinner, stronger, and more optically pure than ever before. Today’s ultra thin glass solutions have shattered previous limitations, achieving what was unthinkable just five years ago. The thinnest commercially available cover glass now measures a remarkable 0.3mm – about three sheets of paper – while maintaining military-grade durability standards.

The Science Behind Ultra-Thin Durability

Advanced Material Composition

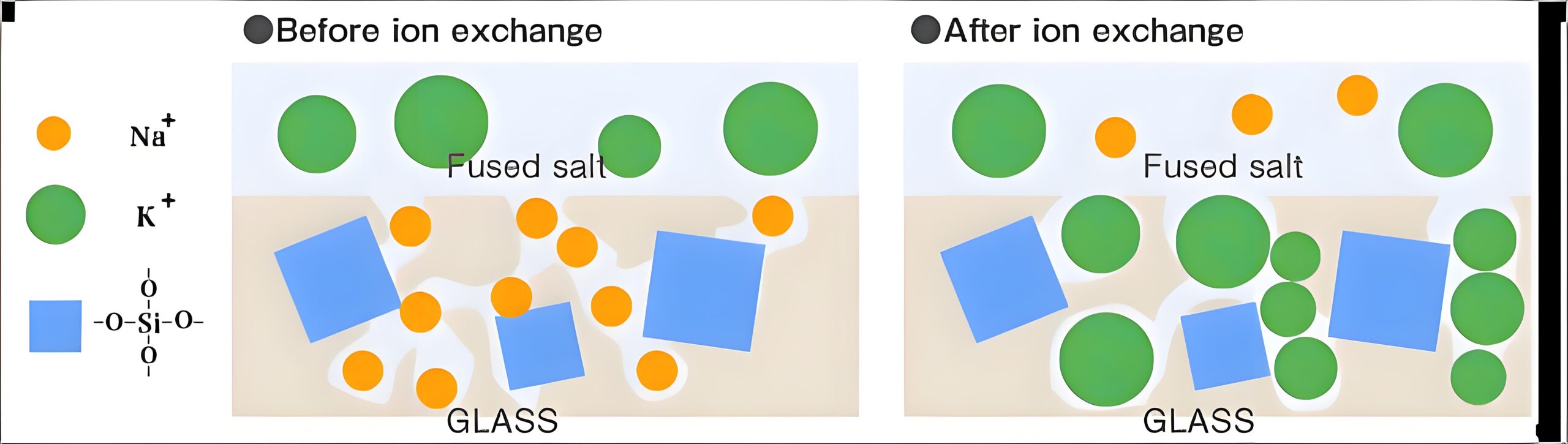

At the heart of modern ultra thin glass technology lies specially formulated aluminosilicate glass:

-

Chemical strengthening through ion exchange creates a compressive stress layer

-

Precision composition controls thermal expansion characteristics

-

Nano-scale surface treatments enhance both hardness and flexibility

Manufacturing Breakthroughs

Cutting-edge production methods enable these unprecedented capabilities:

-

Down-draw process maintains ±0.03mm thickness tolerance

-

Laser edge polishing eliminates micro-cracks that cause failures

-

In-line optical inspection detects sub-micron defects

Performance That Defies Expectations

Optical Excellence

-

>92% light transmission across visible spectrum

-

<0.5% haze for perfect clarity

-

Anti-reflective options with <1.5% reflectivity

Mechanical Superiority

-

1.5m drop survival at just 0.5mm thickness

-

8H pencil hardness (resists keys, coins, and tools)

-

200,000+ bend cycles for foldable applications

Transformative Applications

Smartphone Revolution

-

True edge-to-edge displays with 0.3mm cover

-

Under-display cameras require ultra-pure optics

-

5G signal transparency without interference

Foldable Device Innovation

-

0.5mm glass withstands 3mm bend radius

-

Hybrid polymer-glass stacks prevent cracking

-

Crease-free viewing after thousands of folds

Automotive Advancements

-

Vibration-resistant 0.7mm solutions

-

-40°C to 105°C operational range

-

Heated glass options for winter conditions

Selecting the Right Ultra Thin Glass Solution

Design Considerations

-

Bend requirements (static vs. dynamic folding)

-

Impact protection needs (consumer vs. industrial)

-

Environmental factors (temperature, humidity, UV)

Specification Checklist

-

Thickness tolerance (±0.03mm standard)

-

Surface compression (minimum 700MPa)

-

Optical coatings (AR, AF, AG options)

-

Edge treatment specifications

The Cutting Edge of Ultra-Thin Technology

Emerging Innovations

-

Self-healing surfaces repair minor scratches

-

Dynamic privacy filters switch on demand

-

Integrated sensors for touch and pressure

Future Outlook

-

0.2mm glass in development

-

Graphene-enhanced formulations

-

Energy-generating surfaces

-

Ultra-Thin Glass: Revolutionizing Electronic Displays

Introduction

Ultra-thin glass (UTG) is a cutting-edge material renowned for its exceptional flexibility, durability, and optical clarity. With thicknesses typically ranging from 30 to 100 microns, UTG is increasingly becoming the preferred choice for next-generation electronic displays, including foldable smartphones, tablets, OLED screens, and wearable devices. Its superior resistance to scratches, high thermal stability, and lightweight properties make it ideal for modern electronics demanding both performance and aesthetics.

Key Applications in Electronic Displays

-

Foldable & Flexible Screens

-

Enables slim, lightweight, and bendable displays for smartphones (e.g., Samsung Galaxy Z Fold/Flip series).

-

Offers better durability compared to polymer-based solutions, reducing creasing and wear.

-

-

OLED & MicroLED Displays

-

Serves as an optimal substrate due to its high transparency and thermal resistance.

-

Enhances color accuracy and touch sensitivity in high-end TVs and monitors.

-

-

Wearable Devices

-

Used in smartwatches (e.g., Apple Watch, Samsung Galaxy Watch) for scratch-resistant, lightweight cover glass.

-

-

Automotive & Curved Displays

-

Applied in car infotainment systems and curved dashboards for seamless, high-strength interfaces.

-

Leading Ultra-Thin Glass Material Brands

When selecting UTG for electronic displays, key manufacturers dominate the market with advanced technologies:

-

Schott (Schott UTG)

-

A pioneer in UTG, supplying Samsung’s foldable phones.

-

Features high bendability (radius < 3mm) and superior surface hardness.

-

-

Corning (Willow Glass, Ultra-Slim Glass)

-

Known for Willow Glass (100μm thickness), used in flexible OLEDs and wearables.

-

Offers exceptional thermal and chemical stability.

-

-

AGC (Dinorex UTG)

-

Provides high-impact resistance and optical clarity for automotive displays.

-

-

Nippon Electric Glass (NEG)

-

Specializes in thin, chemically strengthened glass for foldable devices.

-

-

Xinyi Glass (China)

-

Emerging as a cost-effective supplier for mid-range foldable devices.

-

Why Choose Ultra-Thin Glass Over Polymers?

Property UTG Polymer (e.g., CPI) Hardness High (scratch-resistant) Prone to scratches Optics Excellent clarity Slight yellowing/haze Thermal Stability Stable up to 500°C Degrades at high temps Fold Durability 200,000+ folds ~100,000 folds

Future Trends

-

Thinner Formats (≤20μm) for rollable displays.

-

Hybrid UTG-Polymer Laminates to enhance impact resistance.

-

Sustainable Production with reduced energy consumption.

Conclusion

Ultra-thin glass is transforming the electronics industry by enabling slimmer, flexible, and more durable displays. Brands like Schott, Corning, and AGC lead in material innovation, ensuring high performance for premium devices. As demand for foldable and wearable tech grows, UTG will remain a critical enabler of next-gen screens.

-