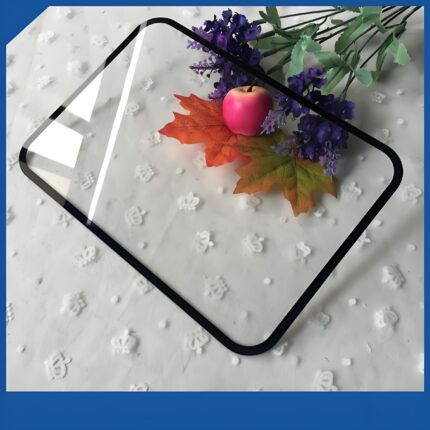

Ultra Thin Custom Cover UTG Glass: Precision Engineering for Next-Generation Devices

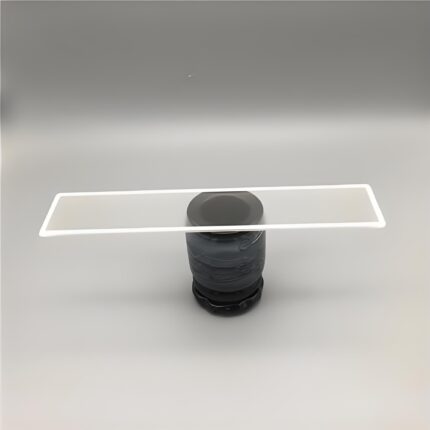

Ultra-Thin Glass (UTG) for Flexible and Foldable Displays

Our UTG (Ultra-Thin Glass) delivers exceptional flexibility, durability, and optical clarity for next-generation devices. With thicknesses as low as 0.1mm, it enables seamless folding and bending without compromising strength. Perfect for foldable smartphones, wearables, and innovative displays, it offers superior scratch resistance, high transparency, and reliable performance. Customizable coatings and shapes available. Ideal for cutting-edge applications demanding lightweight, robust, and high-quality cover glass solutions.

The Revolution of Ultra-Thin Custom Cover UTG Glass Technology

Imagine holding a piece of glass thinner than a human hair that can withstand daily impacts and maintain perfect optical clarity. This isn’t science fiction – it’s the reality of modern ultra-thin cover glass technology. As devices continue evolving toward lighter, more flexible form factors, the demand for exceptionally thin yet durable cover glass has skyrocketed. Our ultra-thin custom cover glass solutions represent the cutting edge of this transformation, enabling product designers to create devices that were previously impossible.

The journey to perfect ultra-thin glass begins with understanding the unique challenges of working with materials measuring just 0.1-0.5mm thick. Conventional manufacturing techniques simply don’t apply at these scales. That’s why we’ve developed specialized handling and processing methods that maintain integrity while achieving precise specifications. Our cleanroom facilities feature custom-designed equipment that gently guides these delicate materials through each production step without compromising their structural or optical properties.

Advanced Manufacturing Capabilities for Ultra-Thin Applications

Working with ultra-thin glass requires more than just specialized equipment – it demands a completely different approach to manufacturing. Our production process incorporates several proprietary technologies that ensure consistent quality and performance. The precision cutting phase utilizes laser systems that create clean edges without micro-cracks that could compromise strength. We’ve developed a unique chemical strengthening process that creates deeper compression layers relative to glass thickness, resulting in exceptional durability despite the minimal material thickness.

Our technical team has pioneered handling techniques that prevent damage during processing and assembly. We use vacuum chuck systems and specialized carrier plates that distribute pressure evenly across the glass surface. For particularly delicate applications, we can process glass while it’s mounted on temporary rigid substrates that are removed after completing the manufacturing process. This attention to detail throughout production separates our ultra-thin glass from competitors’ offerings.

Exceptional Performance Characteristics

Don’t let the thin profile fool you – our ultra-thin glass delivers outstanding performance across multiple metrics. The chemical strengthening process creates surface compression levels exceeding 800 MPa, providing remarkable resistance to scratches and impacts. Despite its minimal thickness, our glass maintains excellent optical properties with light transmission exceeding 91% and haze values below 0.5%. These characteristics make it ideal for display applications where every photon matters.

The flexibility of ultra-thin glass opens new design possibilities previously unavailable to product engineers. Our thinnest variants can bend to radii under 20mm without fracturing, enabling innovative form factors and flexible display applications. This flexibility doesn’t come at the expense of thermal performance either – our glass maintains dimensional stability across temperature ranges from -40°C to 150°C, ensuring reliable performance in diverse environmental conditions.

Application-Specific Solutions

Wearable Technology: For smartwatches, fitness trackers, and AR/VR devices, our ultra-thin glass reduces weight while maintaining durability. We can create custom shapes with precise cutouts for sensors and buttons, all while meeting the stringent impact resistance requirements these devices demand.

Flexible Displays: Our ultra-thin glass serves as an ideal substrate for flexible OLED displays, providing superior barrier properties compared to polymer solutions. The glass’s inherent rigidity during processing combined with flexibility in the final application offers the best of both worlds for display manufacturers.

Medical Sensors: In medical applications where minimal thickness is critical for comfort and functionality, our glass provides chemical resistance against disinfectants while maintaining optical clarity for sensors and displays. We offer biocompatible coatings for direct-skin applications.

Consumer Electronics: From foldable smartphones to ultra-lightweight tablets, our glass enables the next generation of mobile devices. We work with device manufacturers to optimize thickness, weight, and performance for specific product categories.

Technical Specifications

| Parameter | Specification Range | Testing Method |

|---|---|---|

| Thickness | 0.1mm – 0.5mm | Laser measurement |

| Dimensional Tolerance | ±0.02mm | Optical comparator |

| Surface Compression | > 800 MPa | Surface stress meter |

| Flexural Strength | > 700 MPa | 4-point bend test |

| Optical Transmission | > 91% | ASTM D1003 |

| Thermal Stability | -40°C to 150°C | MIL-STD-202 |

| Minimum Bend Radius | < 20mm | Mandrel test |

| Surface Hardness | ≥ 6 Mohs | ASTM E384 |

| Weight (0.2mm thickness) | < 500g/m² | Gravimetric measurement |

| Chemical Resistance | Class A (alkali) / Class B (acid) | DIN 12116 / DIN 12111 |

Partnering for Innovation

Developing successful ultra-thin glass applications requires more than just manufacturing capability – it demands technical partnership. Our engineering team works closely with clients throughout the development process, from initial concept through mass production. We provide design-for-manufacturability feedback, prototype support, and production scaling assistance. Our application engineers understand the challenges of working with ultra-thin materials and can recommend solutions based on experience with similar applications.

We maintain strict confidentiality protocols to protect your intellectual property throughout the development process. Our quality systems ensure consistent performance across production runs, with statistical process controls that monitor critical parameters in real-time. Whether you need prototypes for concept validation or high-volume production, we have the expertise and capacity to meet your requirements.

Contact our technical team today to discuss how our ultra-thin custom cover glass can enable your next breakthrough product. We’ll provide samples and technical data specific to your application requirements within 48 hours of initial consultation.