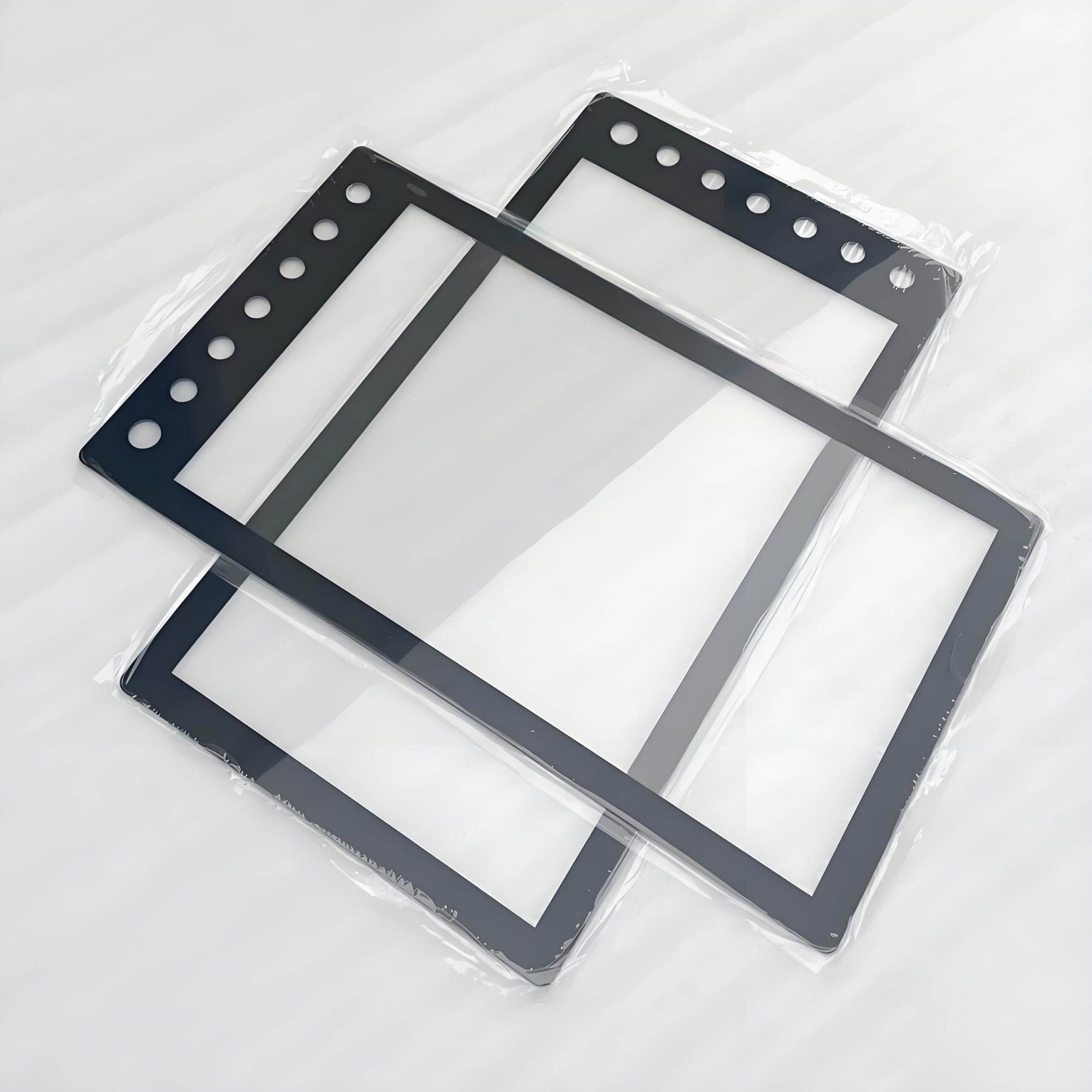

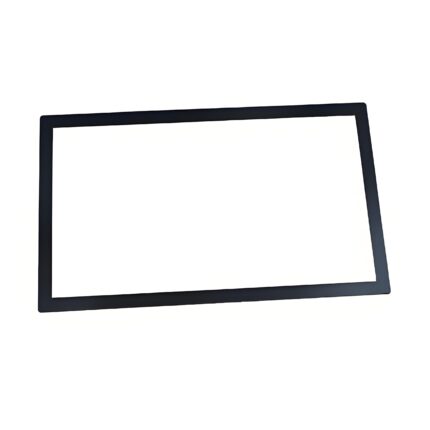

Ultra-Clear Chemically Strengthened Glass

This high-performance Chemically Strengthened Glass offers exceptional optical clarity and superior strength through an advanced chemical strengthening process. It features excellent impact and scratch resistance, making it ideal for high-end displays, touch screens, and protective covers. With its ultra-smooth surface and outstanding durability, it ensures reliable performance in consumer electronics, medical devices, and industrial applications. Custom sizes, thicknesses, and coatings are available to meet specific requirements.

The Unseen Strength: Why Ultra-Clear Chemically Strengthened Glass Changes Everything

1 That First Moment of Clarity

I still remember the first time I held a sheet of ultra-clear chemically strengthened glass up to the light. We were in the factory lab, and my colleague—a veteran with twenty years in glass manufacturing—smiled as I gasped. “It’s like looking through air, isn’t it?” he said. That moment crystallized for me what makes this material extraordinary: it disappears.

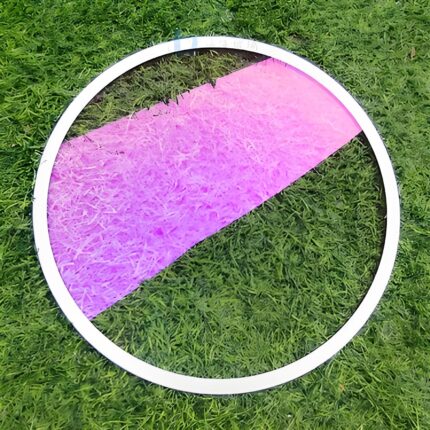

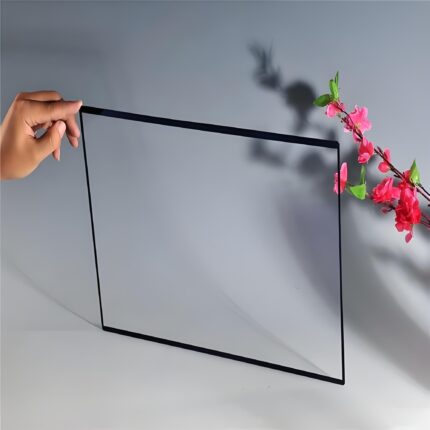

This isn’t ordinary glass. Ultra-clear chemically strengthened cover glass represents the pinnacle of both optical excellence and mechanical performance. Unlike standard glass, which often has that faint greenish tint when you look at its edge, ultra-clear glass offers near-perfect transparency. But the real magic happens when this clarity meets the incredible strength of chemical strengthening.

2 The Alchemy of Invisible Strength

So how do you make glass both stronger and clearer? The secret lies in two processes working in harmony. First, we start with ultra-low-iron glass composition. Regular glass gets its greenish tint from iron impurities—something I learned the hard way when our team spent three months troubleshooting discoloration issues. By reducing iron content to below 0.01%, we achieve that crystal-clear appearance that designers love.

Then comes the chemical strengthening magic. The glass gets immersed in a molten salt bath at precisely 410°C (I’ve burned myself enough times to respect that temperature). What happens next is molecular alchemy: smaller sodium ions in the glass surface swap places with larger potassium ions from the bath. This ion exchange creates massive compressive stress on the surface—like an invisible shield that makes the glass incredibly difficult to scratch or break.

3 Why Customization Isn’t Just Luxury—It’s Necessity

Early in my career, I made the mistake of thinking one strength profile could fit all applications. Then we got a project from a medical device company that needed glass that could withstand both autoclave sterilization and daily impacts. That’s when I truly understood the need for customization.

Different applications demand different stress profiles. For a smartwatch that gets bumped against doors daily, we might create a deeper compression layer (around 50μm) to prevent deep scratches. For a thin smartphone that might experience bending in someone’s pocket, we might optimize for higher surface compression (up to 800 MPa). The beauty of modern chemical strengthening is that we can tune these parameters like a pianist tunes strings.

4 The Manufacturing Tightrope Walk

Producing this glass feels like walking a tightrope every day. The ultra-clear composition requires pristine raw materials—any contamination shows up like a smudge on a camera lens. We once had an entire batch rejected because of microscopic inclusions that most manufacturers would overlook. Our client was designing museum display cases where even the slightest imperfection would be noticeable under gallery lighting.

The chemical strengthening process demands even more precision. The salt bath chemistry must be maintained within strict parameters. Too much calcium contamination? The strengthening depth becomes inconsistent. Bath temperature fluctuating by just 5°C? That changes the ion exchange rate. It’s finicky work that separates adequate glass from exceptional glass.

5 Real-World Performance That Surprises Even Engineers

I’ll never forget the time our engineering team designed what we thought was an overly rigorous test protocol. We were working with a client on automotive center console displays, and we subjected our ultra-clear strengthened glass to thermal cycling (-40°C to 85°C), humidity testing, and mechanical impact tests. The glass didn’t just survive—it performed so well that the client accused us of faking the results until they replicated them in their own lab.

This performance translates to real benefits: retail touchscreens that look brand new after years of frantic customer poking, marine navigation displays that resist salt spray and impacts, and medical devices that withstand both impacts and repeated sterilization. The combination of optical clarity and durability enables designs that simply weren’t possible before.

6 What’s Next? The Future Is Even Clearer

The innovation continues at a breathtaking pace. Right now, we’re working on developing even more environmentally friendly processes—recovering and reusing more of our potassium nitrate bath materials. We’re also seeing exciting developments in combining chemical strengthening with other functionalities: integrated sensors, improved anti-fingerprint coatings, and even self-healing surface layers.

Perhaps most exciting is the work happening with curved ultra-clear glass. The automotive industry wants seamlessly curved displays that are both optically perfect and incredibly durable. It’s challenging work—the strengthening process becomes much more complex on curved surfaces—but the results are worth it.

What continues to surprise me after all these years isn’t just the technology itself, but what it enables. When glass becomes both invisible and indestructible, it ceases to be a barrier and becomes an invitation—to touch, to interact, to connect. And that, ultimately, is why we keep pushing this technology forward.