The Unmatched Advantages of Glass Lens in Modern Touch Technology

Superior Touch Performance with Advanced Glass Lens Solutions

In modern touch technology, Glass Lens components deliver unmatched clarity, durability, and responsiveness compared to plastic alternatives. At [Company Name], we specialize in precision-engineered Glass Lens solutions that meet the rigorous demands of consumer electronics, automotive displays, and industrial equipment.

Our Glass Lens products offer:

-

92%+ light transmission for crystal-clear displays

-

7-8H scratch resistance through chemical strengthening

-

Stable performance from -40°C to 120°C

With 15+ years of expertise, we provide complete Glass Lens OEM services including custom cutting, edge polishing, and specialty coatings (anti-glare, anti-fingerprint). Fast 5-day prototyping and 15-day volume production help bring your products to market faster without compromising quality.

Engineers trust our Glass Lens solutions for:

✓ Longer product lifespan (5-7 years vs plastic’s 1-2)

✓ Lower total cost of ownership

✓ Consistent performance in harsh environments

The Unmatched Advantages of Glass Lens in Modern Touch Technology

In today’s fast-paced digital world, touch technology has become an integral part of our daily lives. From smartphones and tablets to industrial control panels and automotive displays, the demand for high-performance touch interfaces continues to grow. At the heart of these advanced systems lies a critical component: the Glass Lens. As a leading manufacturer in the industry, we understand why more engineers are choosing Glass Lens solutions over plastic alternatives.

Why Glass Lens Dominates Modern Touch Applications

The superiority of Glass Lens in touch technology stems from its unique physical and optical properties. Unlike plastic alternatives, glass offers:

-

Exceptional Clarity & Light Transmission: With up to 92% light transmittance, Glass Lens ensures vibrant, distortion-free displays—essential for high-resolution screens.

-

Superior Scratch Resistance: Rated at 7-8H on the Mohs scale, our chemically strengthened Glass Lens withstands daily wear far better than plastic (3-4H).

-

Temperature Stability: Performs flawlessly in extreme conditions (-40°C to 120°C) where plastics warp or discolor.

-

Long-Term Durability: While plastic yellows and scratches over time, Glass Lens maintains optical clarity for years of heavy use.

These characteristics make Glass Lens the preferred choice for mission-critical applications where reliability can’t be compromised.

Precision Manufacturing for Demanding Applications

Our Glass Lens solutions are engineered to meet the most stringent requirements across industries:

1. Consumer Electronics

-

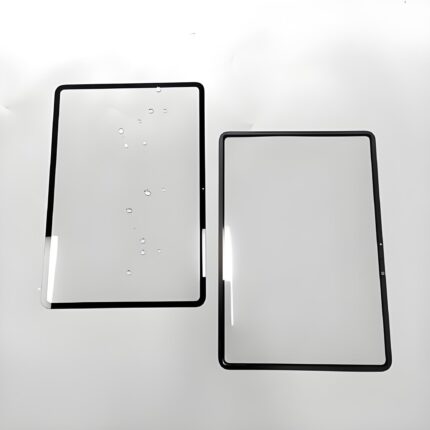

Smartphones/Tablets: Ultra-thin (0.3-1.1mm) designs with anti-fingerprint coatings

-

Wearables: Curved edges for ergonomic comfort without sacrificing strength

2. Automotive Displays

-

Optical bonding solutions for vibration resistance

-

Anti-glare treatments for sunlight readability

3. Industrial & Medical Equipment

-

Chemical-resistant surfaces for sterilization compatibility

-

EMI shielding options for sensitive environments

Our Glass Lens OEM Capabilities

As a specialist Glass Lens manufacturer, we offer complete OEM services:

✅ Custom Geometry

-

Laser cutting to ±0.03mm tolerances

-

2.5D/3D edge polishing options

-

Precise hole drilling for sensors/cameras

✅ Advanced Strengthening

-

Chemical tempering (up to 800MPa compression)

-

Thermal shock resistance testing

✅ Surface Treatments

-

Anti-reflective (92%+ transmittance)

-

Oleophobic coatings (110° contact angle)

-

Privacy filter integration

Faster Time-to-Market Without Compromise

We understand speed matters in product development. That’s why we offer:

-

5-Day Prototyping: Get functional samples before your next team meeting

-

15-Day Volume Production: Scale quickly with consistent quality

-

Emergency 72-Hour Service: For mission-critical projects

Our vertically integrated facility handles everything from material selection to final inspection under one roof—eliminating supply chain delays.

Cost-Effective Solutions Across Volumes

While Glass Lens carries a higher initial cost than plastic, our clients achieve better ROI through:

-

5-7 Year Lifespan vs plastic’s 1-2 years

-

<1% Failure Rate in field deployments

-

Zero Maintenance requirements

We work closely with your team to optimize designs for manufacturability, often reducing per-unit costs by 20-30% through intelligent material selection and process engineering.

The Future of Glass Lens Technology

We’re investing in next-gen Glass Lens innovations:

-

Flexible Glass Solutions for foldable displays

-

Self-Healing Nanocoatings that repair minor scratches

-

Energy-Efficient Compositions that reduce device power consumption

Why Partner With Us?

✔ 15+ Years focused exclusively on Glass Lens technology

✔ ISO 9001/IATF 16949 certified manufacturing

✔ 1.2 Million+ monthly production capacity

✔ 24/7 Engineering Support from concept to production

Experience the Glass Lens Difference

Ready to elevate your touch technology? Contact our specialists today for:

-

Free design consultation

-

Material samples

-

Project cost analysis

Let’s discuss how our Glass Lens solutions can give your product the competitive edge it deserves.

Weiman Tech – Where Advanced Touch Technology Meets Precision Glass Manufacturing