Silk Screened Gorilla Glass Custom Printed Cover Glass for Premium Displays

Silk-Screened Corning Gorilla Glass combines legendary impact resistance with crisp, durable printing for premium branding. Our ceramic inks withstand scratches, chemicals, and UV exposure while maintaining the glass’s original strength. Ideal for medical devices, automotive displays, and consumer electronics requiring logos, borders, or functional markings. Custom designs, precise opacity control, and 5B adhesion rating guaranteed. Enhance your product’s aesthetics without compromising protection. Request free design consultation and samples today.

When Branding Meets Brilliance: The Art of Silk Screened Gorilla Glass

Let’s talk about first impressions. In today’s competitive market, your product’s display isn’t just a functional component—it’s a branding canvas. That’s where our silk-screened Corning Gorilla Glass comes into play. We’re combining the industry-leading durability of Gorilla Glass with precision silk-screen printing to create cover glass that not only protects your display but also enhances your brand identity. Whether you need subtle logo placement, decorative borders, or functional light-blocking areas, our printing process delivers crisp, durable markings that withstand the same rigorous conditions as the glass itself.

The magic happens when world-class materials meet expert craftsmanship. Our printing technicians have spent years perfecting the art of decorating Gorilla Glass, developing techniques that ensure perfect registration, consistent opacity, and exceptional adhesion. We understand that every micron matters when you’re working with premium materials, which is why we maintain strict controls throughout our printing process. From medical devices that require precise warning labels to luxury automotive displays with elegant branding, our silk-screened Gorilla Glass helps your products make the right statement—before anyone even turns them on.

Technical Excellence: How We Transform Gorilla Glass Into Brand Assets

The Silk-Screening Process: Precision Meets Durability

Our silk-screen printing process begins with surface preparation. Each Gorilla Glass panel undergoes thorough cleaning to ensure optimal ink adhesion. We then use high-tension, precision screens with mesh counts ranging from 200 to 400 threads per inch, depending on the required level of detail and ink deposition. The ceramic-based inks we use are specifically formulated for glass applications, requiring curing at temperatures between 120-180°C to achieve their final properties.

The real challenge in printing on Gorilla Glass lies in maintaining its legendary durability while adding decorative elements. Our inks are engineered to complement the glass’s performance characteristics, creating a unified protective system rather than just a surface decoration. The resulting printed patterns exhibit excellent resistance to scratching, chemicals, and UV exposure, ensuring your branding remains legible and attractive throughout the product’s lifespan.

Table: Performance Specifications of Silk-Screened Gorilla Glass

| Parameter | Standard Performance | Printed Areas Performance | Test Method |

|---|---|---|---|

| Print Adhesion | – | 5B (ASTM rating) | ASTM D3359 |

| Print Scratch Resistance | – | 4H pencil hardness | JIS K5600 |

| Light Transmittance | ≥ 91% | Customizable (0-100%) | ASTM D1003 |

| Chemical Resistance | Excellent | Resists alcohol, solvents | ISO 2812 |

| UV Stability | – | ΔE<3 after 1000h UV exposure | ISO 4892 |

| Thickness Range | 0.4-2.0mm | 0.4-2.0mm | Laser measurement |

| Minimum Feature Size | – | 0.2mm | Microscope |

| Curing Temperature | – | 120-180°C | Process control |

Why Choose Silk-Screened Gorilla Glass for Your Application?

Brand Enhancement Without Compromise

Your branding should enhance your product, not become its weak point. Our silk-screening process maintains the full mechanical and optical performance of Gorilla Glass while adding your custom graphics. The prints don’t just sit on the surface—they become part of the protective system, offering the same resistance to damage as the glass itself.

Design Flexibility Across Applications

We offer complete design flexibility to meet your specific needs:

-

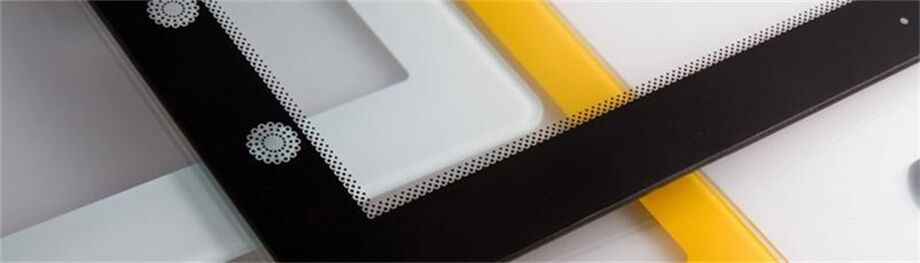

Logo and Brand Element Printing: Crisp, opaque company logos and branding elements

-

Decorative Borders: Consistent, smooth borders in any color

-

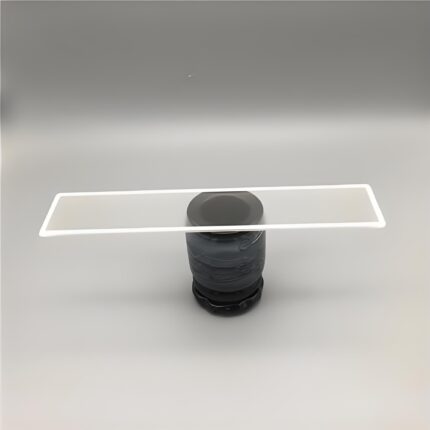

Light-Blocking Areas: Complete light blocking for sensor windows and cameras

-

Functional Markings: Warning labels, instructional text, and regulatory markings

-

Custom Patterns: Unique designs and textures for aesthetic enhancement

-

Proven Performance in Demanding Environments

Our silk-screened Gorilla Glass isn’t just pretty—it’s built to perform. The printed areas maintain their integrity through temperature cycling, humidity exposure, and mechanical stress. They resist fading from UV exposure and maintain their appearance through years of cleaning and use. This makes them ideal for applications where both aesthetics and durability matter.

Applications That Benefit From Our Expertise

-

Medical Devices: Surgical displays with sterilization-resistant markings

-

Automotive Displays: Branded center consoles and instrument clusters

-

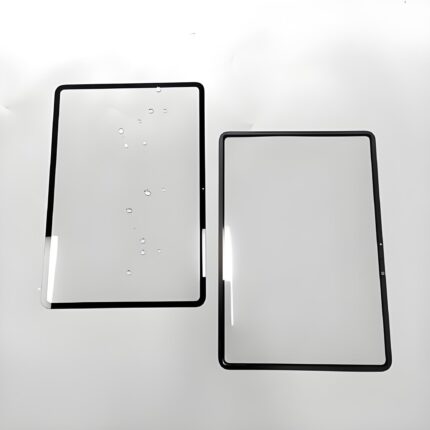

Consumer Electronics: Smartphones and tablets with elegant branding

-

Industrial Equipment: HMIs with durable warning labels and instructions

-

Retail Solutions: POS systems with custom branding and graphics

-

Military and Aerospace: Equipment with permanent identification markings

Our Process: From Concept to Perfection

We don’t just print on glass—we partner with you to ensure your vision becomes reality. Our process begins with design consultation, where we help optimize your artwork for the silk-screen process. We then create custom screens and test prints to ensure perfect color matching and registration. Throughout production, we maintain rigorous quality controls, measuring print thickness, adhesion, and optical properties to ensure consistent results.

Our technical team understands both the art of printing and the science of glass performance. We’ll help you select the right ink system for your application, whether you need maximum opacity, specific chemical resistance, or special visual effects. We can also advise on design considerations that will ensure both manufacturing efficiency and optimal final appearance.

Ready to Enhance Your Products?

If you’re looking for a way to combine superior protection with elegant branding, our silk-screened Gorilla Glass offers the perfect solution. With the durability your products need and the branding they deserve, you can create truly distinctive products that stand out in the marketplace.

Contact us today to discuss your project requirements. Our technical team is ready to help you explore the possibilities and create samples that will exceed your expectations. Let’s make something beautiful together.

-