Premier Partner for Custom Cover Glass Solutions

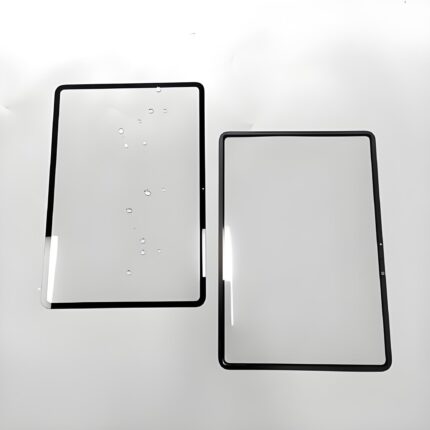

Weiman Tech is your expert OEM partner for Cover Glass Solutions. We precisely cut and shape glass to your exact specs, no matter how unique. Our full in-house services include applying 3M adhesives for easy installation, and adding AR, AG, or AF coatings for superior optics and feel. We strengthen glass both chemically and physically for maximum durability and offer silk screening for branding. Best of all, we work with flexible order quantities to support your project, big or small. Get a perfect glass component tailored for your application.

Weiman Tech: Your Premier Partner for Custom Cover Glass Solutions

In today’s competitive electronics and industrial design markets, the need for high-quality, custom-engineered cover glass has never been greater. Weiman Tech has established itself as a trusted OEM specialist, providing comprehensive cover glass solutions tailored to the precise needs of its clients. From prototyping to mass production, the company combines advanced manufacturing techniques with a client-centric approach to deliver exceptional products.

Customization at the Core: Size, Shape, and Beyond

Weiman Tech’s primary strength lies in its profound flexibility. Unlike many suppliers who offer only standard sizes and shapes, Weiman Tech thrives on customization.

-

Precision Tailoring: Whether you require a unique geometric shape for a cutting-edge medical device, a specific curvature for a wearable, or an unconventional size for an industrial control panel, their engineering team can translate your drawings and specifications into a perfect glass component.

-

Collaborative Process: They work closely with clients throughout the design phase, offering insights on manufacturability and suggesting optimizations for durability and cost-efficiency without compromising the design intent. This partnership ensures the final product not only looks perfect but also performs flawlessly in its intended application.

Comprehensive Value-Added Processing Services

Merely cutting glass to size is not enough. Weiman Tech distinguishes itself by offering a full suite of finishing and enhancement services under one roof, adding significant value and simplifying the supply chain for its customers.

1. 3M Adhesive Lamination for Simplified Assembly

Understanding that integration into final assembly lines needs to be seamless, Weiman Tech offers precise lamination of 3M pressure-sensitive adhesives (PSA). They provide pre-applied adhesive tapes, complete with easy-release liners, onto the cover glass. This service eliminates a messy and precision-dependent step from the client’s production process, reducing assembly time, improving bond consistency, and minimizing the risk of damage or contamination. Customers can specify the exact type of 3M tape required for their project.

2. Advanced Optical Coating Technologies

To meet modern optical clarity and durability demands, Weiman Tech employs state-of-the-art coating techniques:

-

Anti-Reflective (AR) Coating: This coating is applied to both sides of the glass to drastically reduce surface reflection, increasing light transmission and minimizing glare. This is crucial for displays in high-ambient-light environments like outdoor kiosks, automotive dashboards, and high-end instrumentation, improving readability and user experience.

-

Anti-Glare (AG) Coating: AG coating creates a microscopically rough surface that diffuses reflected light, softening harsh reflections and reducing eye strain. It’s a popular choice for touchscreen devices and monitors used in office and industrial settings.

-

Anti-Fingerprint (AF) Coating: An oleophobic coating that makes the glass surface resistant to fingerprints, smudges, and oils from skin contact. This not only keeps displays looking cleaner but also makes them easier to wipe clean, enhancing hygiene and maintenance.

3. Decorative and Functional Printing

For applications requiring branding, logos, or hiding underlying components, Weiman Tech offers high-precision silk screen printing. This process can apply durable ink layers in various colors to the glass, used for masking borders, adding instructional text, or incorporating decorative elements. The prints are designed to be long-lasting and resistant to fading.

4. Chemical and Physical Strengthening: The Foundation of Durability

Perhaps the most critical service for functional cover glass is strengthening. Weiman Tech utilizes two primary methods to ensure its glass can withstand the rigors of everyday use:

-

Chemical Strengthening (Ion Exchange): This process involves submerging the glass in a molten potassium salt bath. Smaller sodium ions in the glass are replaced by larger potassium ions from the bath, creating a deep layer of compressive stress on the surface. This results in glass that is highly resistant to scratches, impacts, and flexing. It is particularly advantageous for thinner glass and complex shapes that may be challenging for thermal tempering.

-

Physical Strengthening (Thermal Tempering): This method involves heating the glass to near its softening point and then rapidly cooling it. This process creates a balance of surface compressive stress and internal tensile stress, making the glass significantly stronger than untreated glass. Furthermore, if it does break, it shatters into small, dull pieces instead of sharp, dangerous shards.

Embracing Flexibility: MOQ and Project Scale

Weiman Tech recognizes that innovation doesn’t always start with a massive order. They have built a operational model that supports both large-scale production runs and smaller, innovative projects. Their flexible Minimum Order Quantity (MOQ) policy is a testament to this. While many OEMs require orders in the thousands, Weiman Tech is willing to work with projects starting at lower volumes, sometimes even for pilot runs or prototype batches. This flexibility allows startups, R&D departments, and companies launching new products to access high-quality custom glass without a prohibitive initial investment.

Conclusion: More Than a Supplier, a Strategic Partner

Weiman Tech positions itself as more than just a manufacturer; it is a solutions provider and a strategic partner in product development. By offering unparalleled customization, a comprehensive range of in-house value-added services, and flexible order quantities, they provide a critical edge to designers and engineers. For anyone in need of reliable, high-performance, and custom-finished cover glass, Weiman Tech represents a capable and responsive OEM partner dedicated to bringing your most demanding visions to life.