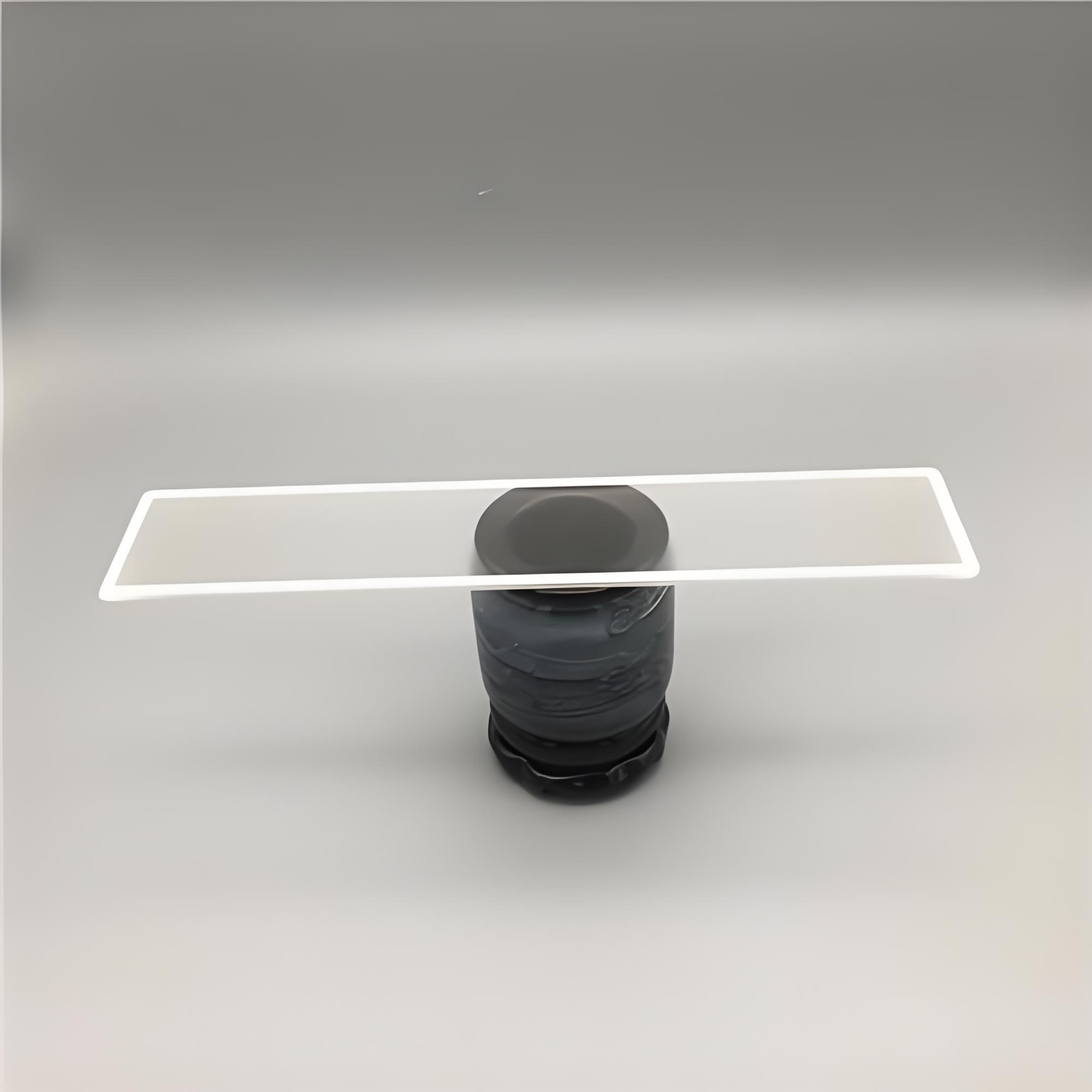

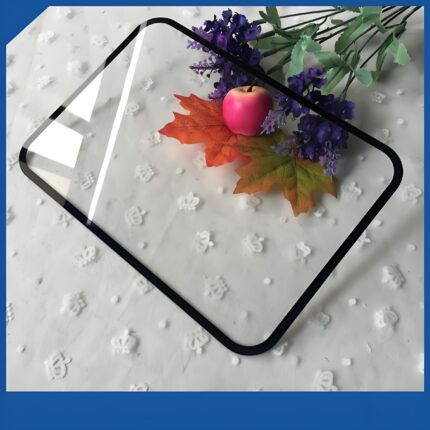

Precision Custom Cover Glass Solutions for Your Unique Applications

Our custom cover glass solutions are engineered to your exact specifications, offering tailored thickness, coatings, and finishes for specialized applications. We manufacture precision glass components for medical, automotive, industrial, and consumer electronics with exceptional optical clarity and durability. Every piece undergoes rigorous quality testing and meets industry-leading performance standards. Partner with us for expert guidance from design to production.

Crafting Excellence: Our Custom Cover Glass Manufacturing Process

What makes our custom cover glass service different? It starts with understanding that your application deserves more than an off-the-shelf solution. Our engineering team works directly with you from concept to production, ensuring every detail meets your exact requirements. We begin with a comprehensive design consultation where we analyze your specific needs – whether it’s unusual curvature requirements, specialized mounting needs, or particular optical characteristics.

Our manufacturing process combines cutting-edge technology with artisan craftsmanship. We utilize advanced CNC grinding and polishing equipment alongside proprietary coating applications to create cover glass that exceeds industry standards. The real magic happens in our custom tooling department, where we create specialized jigs and fixtures specifically for your project. This attention to detail ensures consistent quality across production runs, whether you need fifty pieces or fifty thousand.

Technical Capabilities: Materials and Finishes

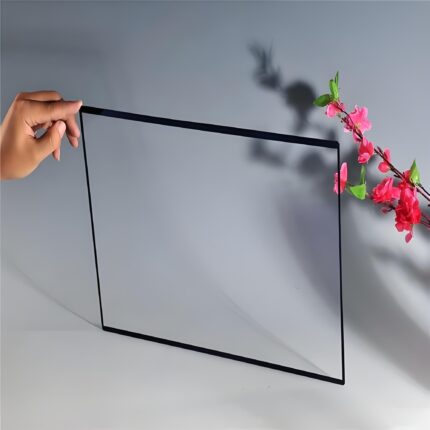

We work with an extensive range of glass materials to meet your specific application requirements. From standard aluminosilicate to specialty chemistries including lithium aluminosilicate and borosilicate glasses, we maintain an extensive inventory of raw materials to accommodate virtually any project. Our material selection expertise helps you balance factors like strength, weight, optical clarity, and thermal properties to find the perfect solution for your application.

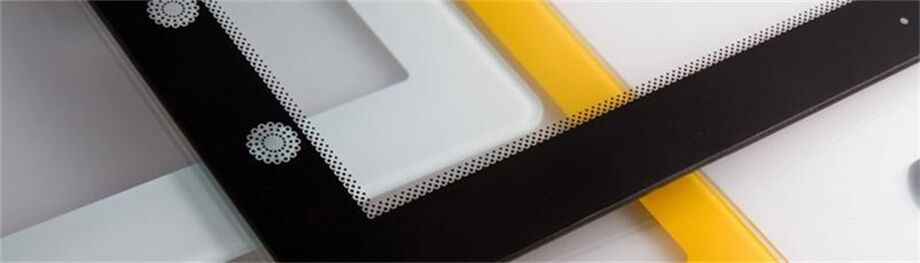

Surface finishing options include:

-

Polished edges with various edge deletion techniques

-

Custom surface textures from matte to mirror finishes

-

Anti-reflective coatings with various performance spectra

-

Anti-fingerprint oleophobic coatings

-

Conductive ITO and silver nanowire coatings

-

Custom color matching for ceramic inks

Quality Assurance and Testing Protocols

Every piece of custom cover glass undergoes rigorous testing to ensure it meets our exacting standards. We employ a multi-stage inspection process that begins with raw material verification and continues through every production step. Our quality lab features advanced measurement equipment including optical coordinate measuring machines, spectrophotometers, and surface profilometers.

Environmental testing capabilities include:

-

Thermal cycling from -40°C to 85°C

-

Humidity testing at 85°C/85% RH

-

Salt spray corrosion testing

-

Taber abrasion and steel wool scratch testing

-

Chemical resistance testing

-

Impact and fracture analysis

Application-Specific Solutions

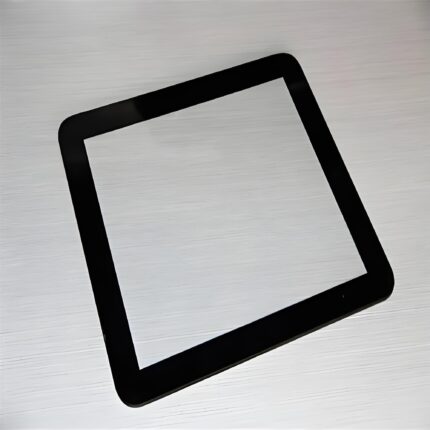

Our custom cover glass serves diverse industries with specialized requirements:

Medical Device Applications: We manufacture cover glass for diagnostic equipment, patient monitoring systems, and surgical displays. These applications require exceptional chemical resistance, anti-fog properties, and compliance with medical safety standards.

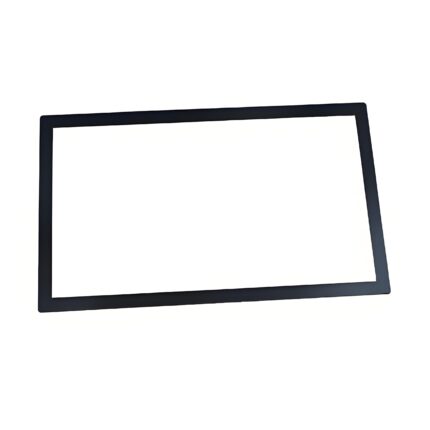

Automotive Displays: Our automotive-grade cover glass meets stringent temperature and durability requirements while maintaining optical clarity in challenging lighting conditions. We specialize in curved solutions for modern dashboard designs.

Industrial and Military Applications: For harsh environment applications, we produce cover glass with enhanced impact resistance, wide temperature range performance, and EMI/RFI shielding properties.

Consumer Electronics: From smart home interfaces to wearable technology, we create cover glass that combines aesthetic appeal with day-to-day durability.

Technical Specifications

| Parameter | Specification Range | Testing Standard |

|---|---|---|

| Thickness | 0.3mm – 6.0mm | ASTM D5947 |

| Size Range | 5mm – 1500mm (diagonal) | Custom tooling |

| Flatness | < 0.1mm/m² | ISO 10110-5 |

| Surface Quality | 20/10 scratch/dig | MIL-PRF-13830B |

| Optical Transmission | > 91% (uncoated) | ASTM D1003 |

| Chemical Strengthening | > 600MPa CS, > 50MPa DOL | Surface stress meter |

| Hardness | ≥ 6 Mohs | ASTM E384 |

| Thermal Stability | -50°C to 150°C | MIL-STD-202 |

| Impact Resistance | 1.5m drop on concrete | IEC 60068-2-32 |

Partnering for Success: Our Collaborative Approach

The journey to perfect custom cover glass begins with a conversation. Our engineering team welcomes challenging applications and complex requirements. We’ve built our reputation on solving problems other manufacturers consider impossible. Whether you need help with design optimization, material selection, or production scaling, we provide expert guidance throughout the development process.

Our project management system ensures transparent communication from initial quotation through production delivery. We provide regular progress updates and involve you in key decision points throughout manufacturing. With facilities in North America, Europe, and Asia, we offer local support with global manufacturing capabilities.

Contact our technical sales team today to discuss your specific application requirements. We’ll provide a comprehensive quotation within 48 hours, including design recommendations and prototyping options. Let us show you why leading OEMs trust us with their most challenging cover glass applications.