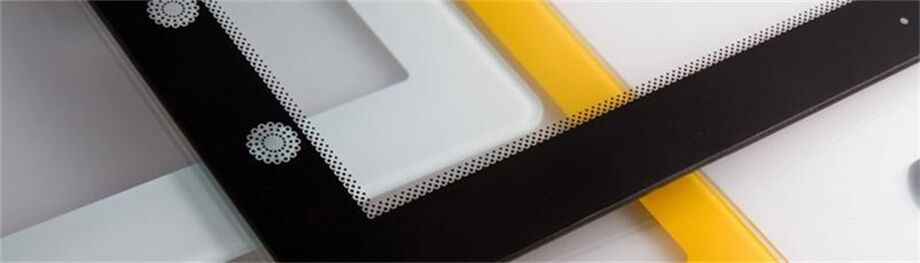

Precision Custom Cover Glass for Electronic Displays

Our custom cover glass transforms how users experience your electronics. We engineer each piece with precision, ensuring exceptional clarity, touch sensitivity, and durability. From smartphones to medical equipment, our solutions withstand drops, scratches, and extreme conditions while making displays shine. Partner with us for truly tailored glass that integrates seamlessly into your designs. Let’s create something remarkable together—reach out to discuss your specific needs.

Engineering the Perfect Custom Cover Glass for Modern Devices

When we first started working with display cover glass fifteen years ago, most manufacturers just wanted something that wouldn’t break during assembly. My how things have changed. Today, that piece of glass needs to be practically invisible while protecting against drops, scratches, and daily wear – all while making colors pop and touch responsiveness feel natural. At our facility in Osaka, we’ve developed some pretty innovative approaches to meeting these competing demands.

The real breakthrough came when we stopped thinking about cover glass as a separate component and started treating it as an integral part of the display system. Our engineers work directly with your team from the early concept stage, asking questions nobody else thinks to ask: How will the glass interact with your specific display technology? What environmental conditions will the device face? How will users actually interact with the interface? This collaborative approach has led to some of our most successful innovations.

Material Science Meets Manufacturing Excellence

Walk through our production facility and you’ll see something pretty unusual – multiple strengthening lines running different chemical compositions simultaneously. We maintain this flexibility because we’ve learned that one size definitely doesn’t fit all when it comes to cover glass. The composition that works perfectly for a smartphone might be completely wrong for a automotive heads-up display or medical monitoring device.

Our chemical strengthening process has been refined through thousands of iterations. We control not just the temperature and time, but the precise agitation of the salt baths and the cooling rates to achieve exactly the right compression profile for each application. For ultra-thin applications, we’ve developed a proprietary process that creates deeper compression layers without distorting the surface flatness. The result is glass that behaves differently – better – than anything you’ve worked with before.

Customization That Actually Means Something

The term “custom” gets thrown around pretty loosely these days. For us, it means genuinely adapting our processes to meet your specific needs. We recently worked with a medical device manufacturer who needed cover glass that could withstand daily disinfection with strong chemicals while maintaining perfect optical clarity. Through multiple iterations, we developed a special coating system that actually became more effective with repeated chemical exposure.

Another client needed help with light transmission issues for a display that would be used in direct sunlight. Instead of just applying a standard AR coating, we developed a multi-layer solution that targeted specific wavelength ranges while maintaining color accuracy. The solution ended up improving battery life because the display could run at lower brightness levels.

Technical Specifications That Matter

| Parameter | Our Standard | Premium Option | Testing Method |

|---|---|---|---|

| Thickness Range | 0.3-2.0mm | 0.3-3.0mm | Laser measurement |

| Thickness Tolerance | ±0.05mm | ±0.02mm | Digital micrometer |

| Surface Compression | >600 MPa | >800 MPa | Surface stress meter |

| Vickers Hardness | 600 HV | 650 HV | Microhardness test |

| Optical Transmittance | >91% | >93% | Spectrophotometer |

| Thermal Shock | Δ100°C | Δ150°C | MIL-STD-202 |

| Impact Resistance | 1.0m drop | 1.5m drop | IEC 60068-2-32 |

| Bending Strength | 400 MPa | 500 MPa | 4-point bend test |

| Chemical Resistance | 24h acid/alkali | 48h acid/alkali | Weight loss method |

Real-World Applications That Push Boundaries

Automotive Displays: We’ve been working with three major automakers on curved display solutions that can handle temperature extremes from -40°C to 105°C. The challenge wasn’t just making glass that could survive these conditions, but ensuring touch functionality would work equally well in freezing cold and extreme heat. Our solution involved developing a special conductive layer system that maintains consistent performance across the entire temperature range.

Medical Equipment: For patient monitoring systems, we created cover glass that maintains readability from extreme angles while resisting disinfectants that would destroy conventional coatings. The anti-glare treatment we developed reduces eye strain for medical staff who spend long hours watching monitors.

Consumer Electronics: Our work with smartphone manufacturers has focused on reducing weight while improving durability. We recently helped a client shave 0.2mm off their cover glass thickness while actually improving drop test performance through better edge compression management.

Why Partnering With Us Feels Different

We know you have choices when it comes to cover glass suppliers. What makes us different is how we approach problems. When you send us your specifications, our engineers don’t just look at whether we can meet them – we look at why you need those specifications and whether there might be a better approach. Sometimes we suggest alternatives that achieve the same end result more efficiently or cost-effectively.

Our production team includes people who’ve been with us since the beginning, and their institutional knowledge makes all the difference. They spot potential issues that automated systems might miss and suggest tweaks to processes that improve outcomes. We maintain relationships with raw material suppliers that give us access to new glass compositions before they’re widely available.

Let’s Start a Conversation

The best projects usually start with a challenging problem. Send us your toughest requirements and let our team show you what real customization looks like. We’ll provide samples that actually meet your specs, not just close approximations. You’ll work directly with our engineering team who can explain not just what we’re doing, but why we’re doing it that way.

Contact us today to schedule a technical consultation. We’ll review your requirements and provide a detailed proposal within 48 hours. Bring your most challenging display problems – we love solving them.