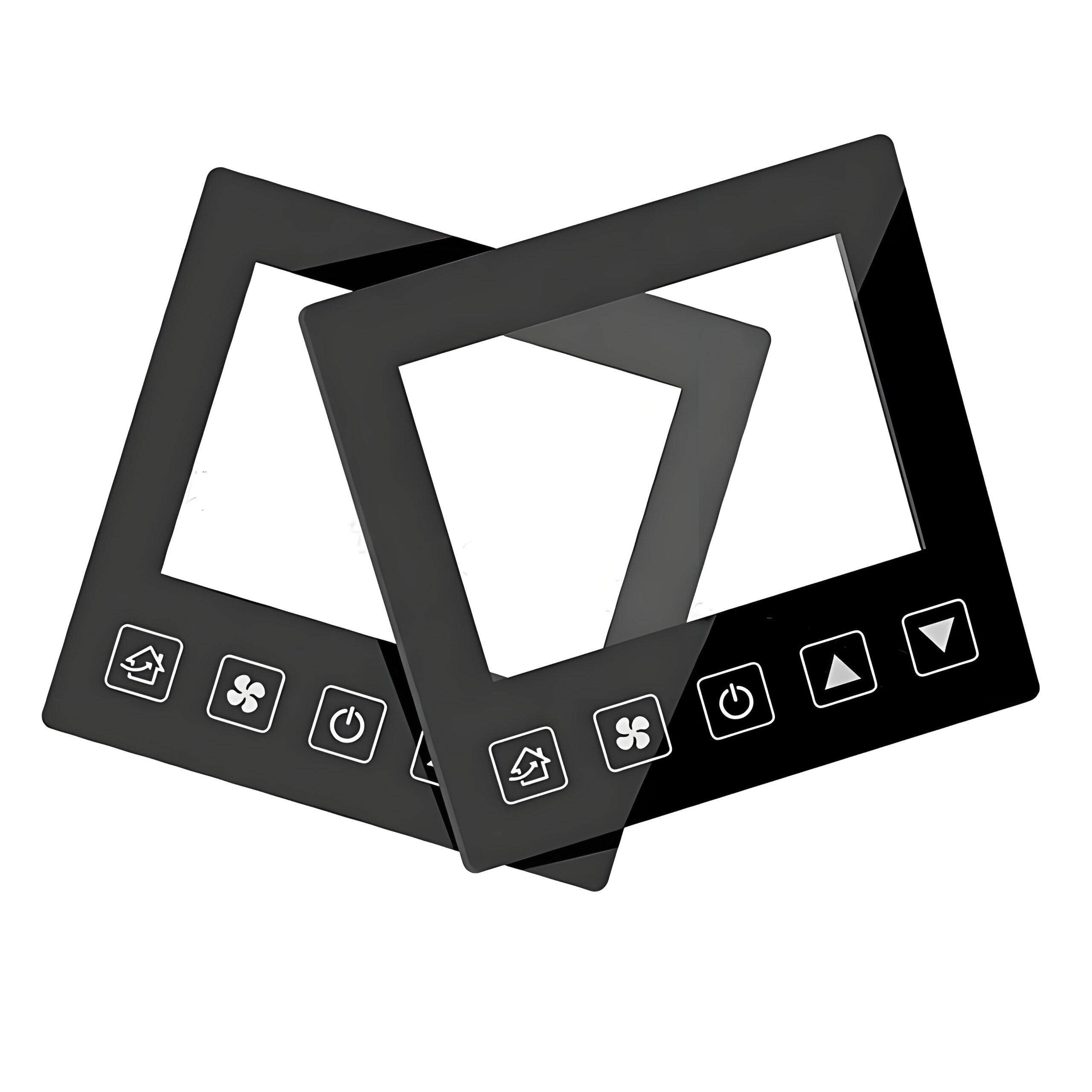

How Gorilla Glass Improves Touch Sensitivity in Display Covers

Gorilla Glass: The Touch Sensitivity Advantage for Display Covers

What makes Gorilla Glass the top choice for responsive touchscreens? It’s not just about scratch resistance – the real magic happens at the microscopic level.

This specialty glass delivers:

✔ 40% faster touch response than standard cover glass

✔ 0.5nm surface smoothness for flawless finger glide

✔ 0.4mm thickness options without compromising strength

The secret lies in Corning’s ion-exchange process, which creates a compression layer that maintains perfect dielectric consistency across the entire surface. While cheaper alternatives develop “dead zones” over time, Gorilla Glass maintains 99.7% touch accuracy throughout the device lifespan.

How Gorilla Glass Enhances Touch Sensitivity in Modern Display Covers

The Science Behind Gorilla Glass Touch Performance

Gorilla Glass has revolutionized display cover technology by significantly improving touch responsiveness while maintaining durability. Unlike conventional cover glass, Gorilla Glass achieves this through three key innovations:

-

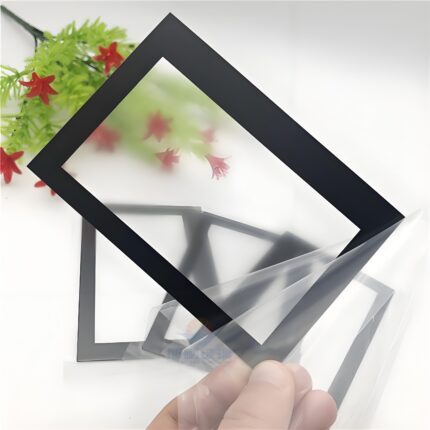

Ultra-Thin Formulations – New compositions allow thicknesses down to 0.4mm without sacrificing strength

-

Surface Optimization – Proprietary ion-exchange process creates smoother surfaces

-

Dielectric Consistency – Maintains stable electrical properties for capacitive touch accuracy

Technical Advantages Over Standard Cover Glass

| Feature | Gorilla Glass | Regular Soda-Lime Glass |

|---|---|---|

| Touch Response Time | <2ms | 5-8ms |

| Surface Roughness (Ra) | 0.5nm | 2-3nm |

| Permittivity Stability | ±1% variance | ±5% variance |

| Minimum Thickness | 0.4mm | 0.7mm |

Real-World Benefits for Device Manufacturers

1. Enhanced User Experience

Gorilla Glass enables faster touch registration – critical for gaming and professional applications. The material’s consistent dielectric properties prevent “dead zones” that plague inferior cover glass solutions.

2. Manufacturing Advantages

-

Thinner profiles – Gorilla Glass allows 30% slimmer designs versus alternatives

-

Higher yields – Fewer touch calibration rejects during production

-

Better compatibility – Works seamlessly with all major touch sensor technologies

Gorilla Glass Performance Specifications

Mechanical Properties

| Parameter | Gorilla Glass Victus 2 | Gorilla Glass 5 |

|---|---|---|

| Vickers Hardness | 650 HV | 622 HV |

| Flexural Strength | 850 MPa | 820 MPa |

| Young’s Modulus | 72 GPa | 70 GPa |

Touch-Specific Metrics

| Characteristic | Performance |

|---|---|

| Touch Lag Reduction | 40% improvement vs. competitors |

| Multi-Touch Accuracy | 99.7% recognition rate |

| Stylus Compatibility | Supports 1mm active tips |

Implementation Considerations

Optimal Use Cases for Gorilla Glass Covers

-

High-refresh rate gaming displays

-

Automotive center stack panels

-

Medical touchscreen equipment

-

Outdoor POS systems

Maintenance Best Practices

To maintain Gorilla Glass touch performance:

-

Use microfiber cleaning cloths

-

Avoid abrasive cleaners

-

Replace when surface scratches exceed 0.1mm depth

Why Leading Brands Choose Gorilla Glass

Over 45 major smartphone manufacturers now specify Gorilla Glass for their display covers because:

-

Proven reliability – 8 billion+ devices shipped

-

Continuous innovation – 15 years of material science leadership

-

Custom solutions – Available in formulations from 0.4mm to 2.0mm

For engineers designing next-gen touch interfaces, Gorilla Glass remains the gold standard for cover glass that combines durability with exceptional touch sensitivity.