How Electronic Cover Glass Enhances Display Performance and Durability

How Electronic Cover Glass Enhances Display Performance and Durability

Today’s premium displays rely on advanced electronic cover glass to achieve both stunning visuals and long-term reliability. The right cover glass solution actively improves display quality by:

-

Maximizing optical clarity (92%+ light transmission) while minimizing reflectivity (<1.5%)

-

Preserving color accuracy with <0.5% haze and neutral tint properties

-

Enabling thinner designs (down to 0.3mm) without sacrificing protection

Durability enhancements include:

✓ 800+ MPa surface compression from chemical strengthening

✓ 6H-9H scratch resistance against daily wear

✓ 1.5m drop survival in smartphone applications

Modern innovations like laser-patterned anti-glare treatments and hybrid polymer-glass composites further bridge the gap between protection and performance. From OLED smartphones to automotive touchscreens, engineered cover glass solutions now play an active role in display enhancement rather than just passive protection.

How Advanced Cover Glass Transforms Display Performance and Protection

The Dual Role of Modern Cover Glass in Display Systems

Today’s cover glass does far more than simply protect displays—it actively enhances their performance. Premium cover glass solutions serve as engineered optical components that:

-

Amplify brightness by minimizing light loss

-

Improve touch sensitivity through optimized dielectric properties

-

Extend display lifespan by shielding against environmental damage

From smartphones to automotive clusters, the right cover glass elevates both user experience and product durability.

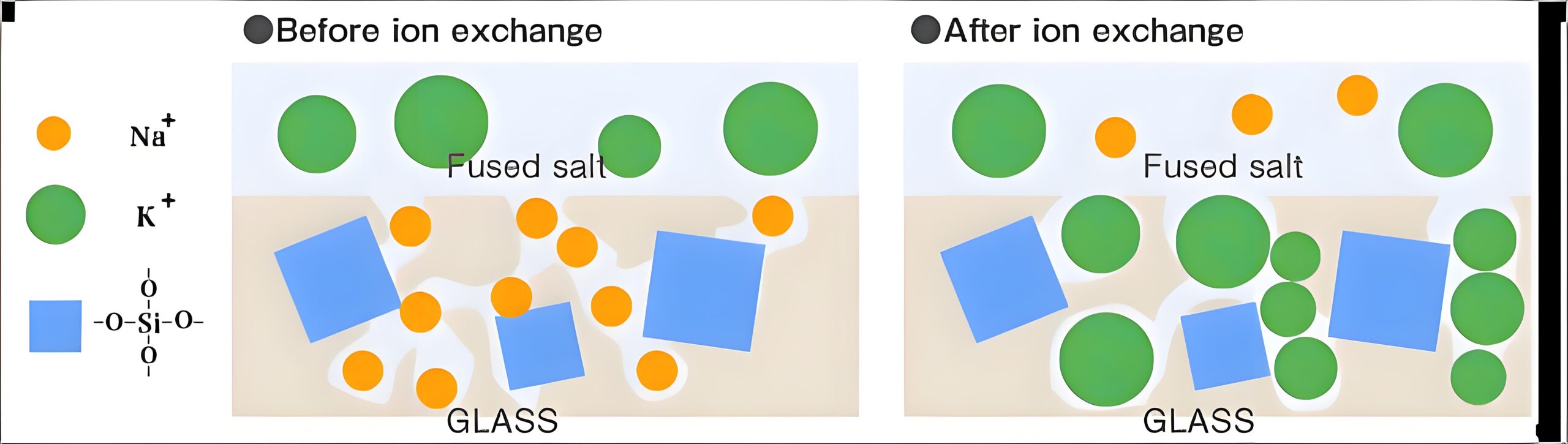

What’s chemical strengthened?

Optical Performance Enhancements

Light Management Capabilities

Advanced cover glass maximizes display output through:

-

92-95% light transmission (vs. 88-90% in standard glass)

-

<1.5% reflectivity with multilayer anti-reflective coatings

-

<0.5% haze for pixel-perfect clarity

Color Fidelity Preservation

Premium formulations maintain accurate color reproduction by:

-

Neutral color tint (ΔE <1.0)

-

Minimizing birefringence in polarized displays

-

Blocking UV wavelengths that degrade OLED materials

Durability Breakthroughs

Structural Reinforcement Technologies

Modern chemically strengthened cover glass achieves:

-

800-1000 MPa surface compression via ion exchange

-

Vickers hardness of 600-700 HV

-

Flexural strength up to 900 MPa

Real-World Protection Metrics

Industry testing verifies:

-

1.5m drop survival on concrete (0.5mm thickness)

-

6H-9H pencil hardness resistance

-

200,000+ bend cycles for foldable devices

Application-Specific Innovations

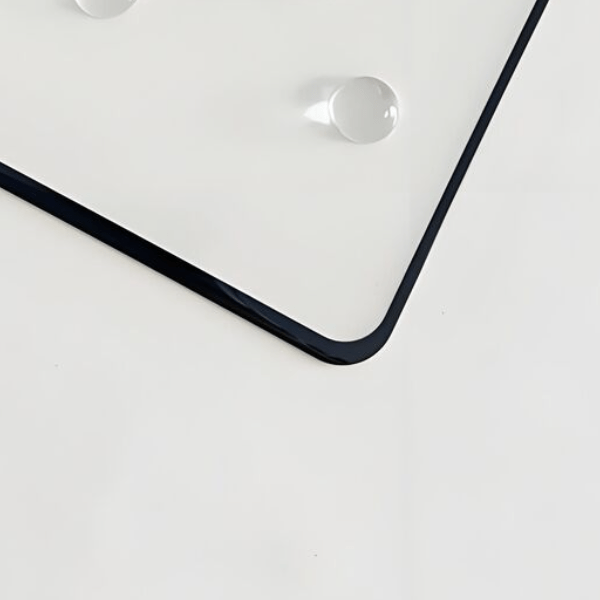

Smartphone Display Solutions

-

0.3mm ultra-thin versions for compact designs

-

Edge stress relief for bezel-less displays

-

Under-display camera compatible formulations

Automotive Grade Protection

-

Vibration-resistant laminated structures

-

Heated glass options for winter climates

-

Sunlight-readable anti-glare treatments

Emerging Flexible Display Tech

-

0.5mm flexible glass with 3mm bend radius

-

Hybrid polymer-glass stacks

-

Crease-free folding performance

Material Science Behind the Advancements

Chemically Strengthened Aluminosilicate

The industry standard offers:

-

Deep ion exchange layers (40-100μm)

-

Optical purity with minimal inclusions

-

Thermal stability up to 400°C

Next-Gen Composite Materials

Innovative alternatives include:

-

Polymer-interlayer hybrids for impact absorption

-

Ceramic-reinforced surfaces for extreme hardness

-

Nano-porous coatings for anti-fingerprint properties

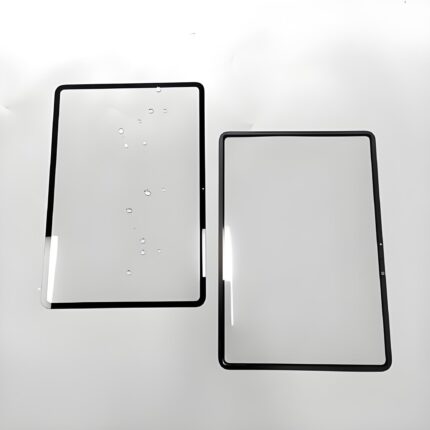

Manufacturing Processes That Enable Performance

Precision Glass Forming

-

Down-draw process with ±0.03mm thickness control

-

Laser edge polishing for strength optimization

-

In-line optical inspection for defect detection

Advanced Coating Technologies

-

Magnetron sputtering for durable AR layers

-

Plasma-enhanced oleophobic treatments

-

UV-cured anti-glare textures

Selecting the Right Cover Glass Solution

Key Specification Considerations

-

Environmental requirements (temperature, humidity, UV)

-

Optical parameters (transmission, haze, reflectivity)

-

Mechanical demands (impact, scratch, bend needs)

-

Special features (conductivity, self-healing, etc.)

Performance Validation Methods

-

Taber abrasion testing for scratch resistance

-

Ball drop impact evaluations

-

Optical spectrometer measurements

-

Environmental chamber aging tests

The Future of Cover Glass Technology

Emerging Innovations

-

Self-healing surfaces with polymer nanocomposites

-

Dynamic privacy filters using PDLC technology

-

Energy-harvesting transparent solar layers

Market Growth Areas

-

Foldable displays (45% annual growth)

-

Automotive touchscreens (12″+ average sizes)

-

AR/VR optics (ultra-low reflectivity needs)