How Chemically Strengthened Glass Protects OLED Displays

How Chemically Strengthened Glass Protects OLED Displays

Modern OLED displays demand cover glass that combines crystal clarity with robust protection. Chemically strengthened glass undergoes an ion-exchange process that creates a compressive stress layer, delivering:

-

800+ MPa surface compression to resist micro-cracks

-

0.3mm thinness without sacrificing impact resistance

-

>92% light transmission for uncompromised brightness

This specialized glass shields fragile OLED materials from:

✓ Daily scratches (6H+ pencil hardness)

✓ Accidental drops (1.5m concrete survival)

✓ UV degradation that causes color shift

Advanced versions now incorporate:

• Anti-reflective coatings (<1.5% glare)

• Edge reinforcement for bezel-less designs

• Flexible variants for foldable OLEDs

How Chemically Strengthened Glass Revolutionizes OLED Display Protection

The Critical Role of Cover Glass in OLED Longevity

Today’s ultra-thin OLED displays require specialized protection that standard glass can’t provide. Chemically strengthened glass has become the industry standard for premium devices because it solves three fundamental challenges:

-

Structural fragility of thin OLED layers

-

Sensitivity to environmental stress (UV, moisture, impacts)

-

Optical interference that degrades display quality

-

What’s chemical strengthened?

The Science Behind Chemical Strengthening

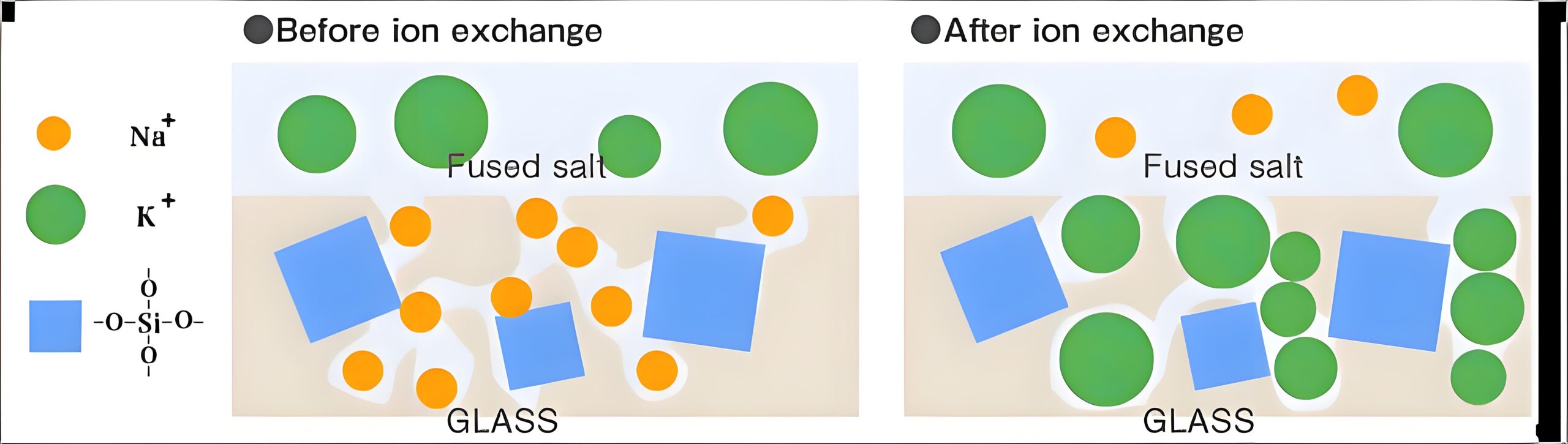

Ion Exchange Process Explained

The transformation occurs through a precise thermal chemical treatment:

-

400°C molten potassium nitrate baths (20+ hours)

-

Sodium-potassium ion substitution creates 40-100μm compression layer

-

800-1000 MPa surface stress (vs. 50-100 MPa in untreated glass)

Material Composition Matters

Premium aluminosilicate formulations offer:

-

Higher ion mobility for deeper strengthening

-

Lower coefficient of thermal expansion

-

Superior optical clarity with fewer impurities

Performance Advantages for OLED Displays

Unmatched Mechanical Protection

Independent testing confirms:

-

6H-9H pencil hardness resists keys and coins

-

1.5m drop survival on concrete (MIL-STD-810G)

-

200% improvement in flexural strength vs. soda-lime glass

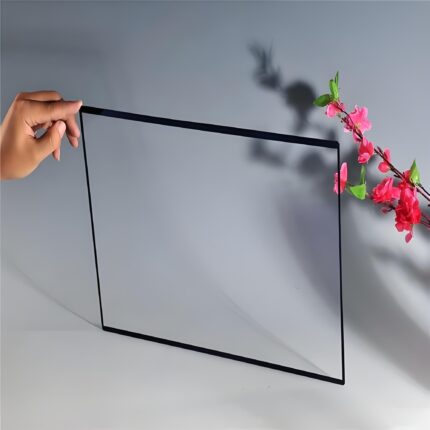

Optical Performance Preservation

Critical for OLED image quality:

-

92-95% light transmission (minimal brightness loss)

-

<0.5% haze prevents image softening

-

UV filtering (blocks 99% of 380nm wavelengths)

Environmental Shielding

Protection against:

-

98% humidity for 1000+ hours

-

-40°C to 85°C thermal cycling

-

Salt spray corrosion (96+ hours)

Advanced Variants for Specific Applications

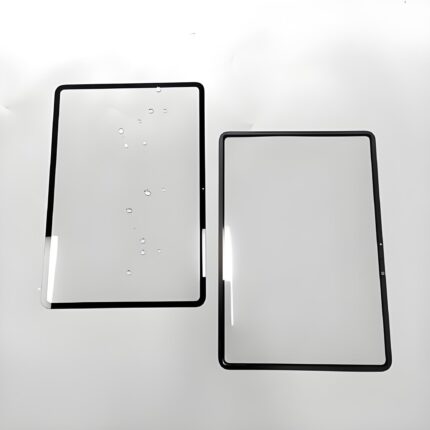

Smartphone Innovations

-

0.3-0.5mm thickness maintains sleek profiles

-

3D formed edges enable true bezel-less designs

-

Laser-cut camera holes for under-display features

Foldable Display Solutions

-

0.5mm flexible versions with 3mm bend radius

-

200,000+ fold cycles without cracking

-

Hybrid polymer-glass stacks for stress distribution

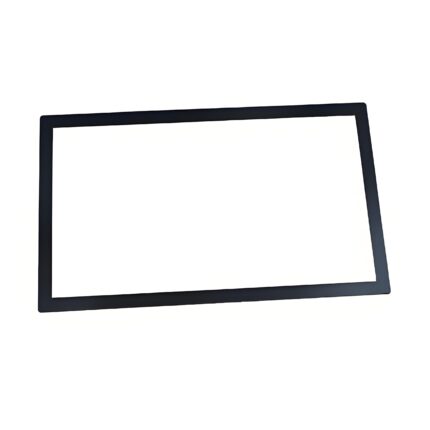

Automotive Grade Options

-

2.0mm thick laminated versions for vibration resistance

-

Heated glass prevents fogging (-30°C operation)

-

Anti-glare coatings optimized for sunlight readability

Manufacturing Breakthroughs

Precision Strengthening Techniques

-

Computer-controlled immersion systems (±1°C accuracy)

-

In-line stress measurement (laser polarimetry)

-

Post-treatment laser annealing for edge strengthening

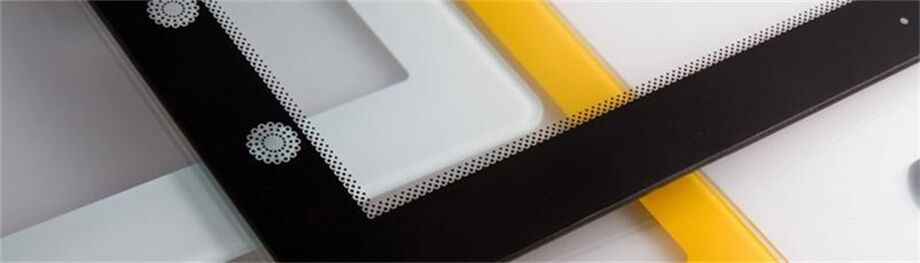

Cutting-Edge Finishing Processes

-

Laser drilling for camera/sensor openings

-

Diamond abrasive edge polishing

-

Nanocoating application chambers

Selection Guide for Product Engineers

Key Specification Considerations

-

Compression depth (40μm minimum for smartphones)

-

Central tension (<50MPa for safety)

-

Thickness tolerance (±0.03mm for assembly)

-

Optical coatings compatibility

Performance Validation

Recommended test protocol:

-

Surface compression (polarimeter)

-

Four-point bend test (ASTM C158)

-

Taber abrasion (ASTM D1044)

-

Environmental aging

Future Innovations on the Horizon

Material Advancements

-

Zirconia-doped formulations for higher hardness

-

Self-healing surface layers

-

Dynamic stiffness adjustment

Manufacturing Improvements

-

Roll-to-roll strengthening for flexible glass

-

AI-driven process optimization

-

In-situ quality monitoring