Gorilla Cover Glass Custom Processing Based on Drawings

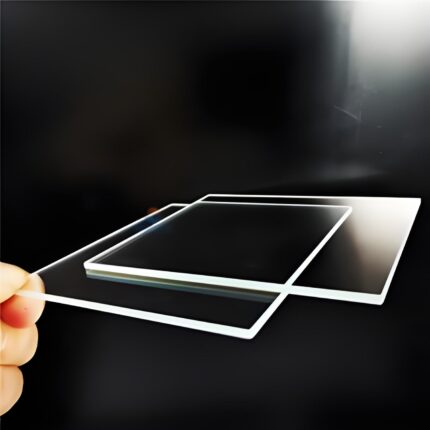

We provide custom processing of Gorilla Cover Glass according to client drawings. With advanced cutting, polishing, drilling, and coating capabilities, each panel is tailored to fit unique device designs. Suitable for smartphones, automotive displays, medical equipment, and smart appliances, our glass combines strength, clarity, and precise craftsmanship. Flexible order quantities, strict quality control, and reliable delivery make us a trusted partner for both prototypes and mass production.

Gorilla Cover Glass Custom Processing Based on Drawings

Professional Manufacturer and Reliable Partner

When it comes to high-performance cover glass, every project has its own requirements. Off-the-shelf materials often fall short—either the dimensions don’t match, or the finishing isn’t right for the intended use. That is why we focus on custom processing of Gorilla Cover Glass according to your drawings. With years of hands-on experience and advanced facilities, our factory is able to translate complex specifications into precise, durable glass components that are ready to install.

A Practical Approach to Customization

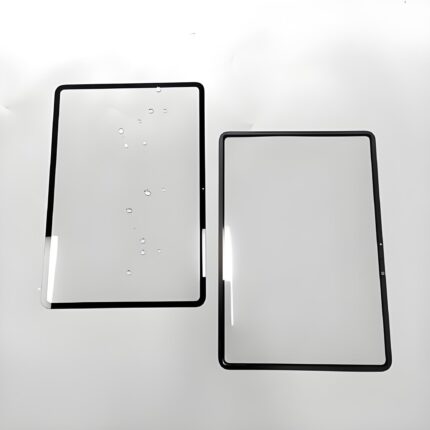

Instead of pushing one-size-fits-all solutions, we listen carefully to what our clients actually need. Sometimes it is a small batch of samples for product testing, sometimes a large production run for an established model. In either case, we take your CAD or PDF drawings as the foundation, and from there we handle the shaping, drilling, edge work, and finishing required to bring the design into reality.

What We Can Do

Our capabilities cover the full spectrum of Gorilla Glass processing:

-

Precision Cutting – Accurate shaping with CNC and laser technology.

-

Edge Treatment – Safety polishing, smooth chamfering, or decorative finishing.

-

Drilling and Slotting – Clean openings for sensors, speakers, or connectors.

-

Surface Coating – Anti-glare, anti-fingerprint, or strengthened layers for better usability.

-

Printing Options – Custom logos, borders, or icons to match product design.

-

Thickness Range – From ultra-thin lightweight panels to reinforced protective glass.

Flexible Order Sizes

Not every client needs mass production immediately. That’s why we support prototypes, pilot runs, and full-scale manufacturing. This flexibility helps reduce risk and makes it easier for you to move from design stage to market launch.

Quality You Can Trust

We treat quality control as a daily routine, not just a final step. Measurements, surface checks, and durability tests are carried out at multiple points during production. After all, Gorilla Glass is chosen because people expect reliability, and we make sure that promise is delivered.

Industries We Serve

Consumer Electronics

From smartphones and tablets to laptops and wearables, Gorilla Glass panels are the silent guardians of daily-use devices. Custom processing ensures that every notch, hole, or curve aligns perfectly with your design.

Automotive Displays

As vehicles become more digital, dashboards and infotainment systems demand glass that is both tough and stylish. Our custom panels withstand vibration and heat while still looking sleek.

Healthcare Devices

Medical equipment requires smooth, easy-to-clean surfaces. Gorilla Cover Glass, processed to precise drawings, protects sensitive electronics and supports hygienic use in clinical environments.

Industrial and Home Applications

Smart appliances, industrial control panels, and even premium kitchen devices now rely on durable cover glass. With tailored designs, these products combine function with visual appeal.

Why Work With Us

More Than Just a Supplier

We are not here to sell you stock sheets of glass. We act as a partner, helping to review drawings, suggest feasible improvements, and ensure that what you receive is exactly what your project requires.

Delivery and Scheduling

Lead times matter. We maintain a responsive production schedule so that urgent samples or bulk orders can be completed without unnecessary delays.

Fair and Transparent Pricing

Our pricing is competitive, but more importantly, it is straightforward. Clients appreciate that there are no hidden charges—just a clear breakdown of costs tied to processing steps and quantities.

Support That Lasts

From the first drawing to after-sales service, our team stays available. If adjustments are needed, or if new projects arise, we treat ongoing cooperation as part of building long-term trust.

Looking Ahead

Innovation and New Demands

Foldable devices, augmented reality systems, and smart wearables are driving the next wave of cover glass requirements. Custom Gorilla Glass processing will only become more essential as designs move beyond traditional flat panels.

Beyond Electronics

Architectural use, aerospace projects, and public information systems are already testing Gorilla Glass in larger or more complex applications. With the right processing, these possibilities expand even further.

Building Partnerships

Our goal is simple: to be the factory you can rely on for every stage of product development. By combining technical expertise, careful craftsmanship, and practical flexibility, we aim to grow together with our clients in today’s competitive market.

Contact Us

If you have drawings or design concepts that need high-quality Gorilla Cover Glass, reach out today. We will provide a quick evaluation, professional advice, and a quotation tailored to your needs.