Electronic Cover Glass: Key Properties and Manufacturing Processes

Electronic Cover Glass: Key Properties and Manufacturing Processes

Modern electronic cover glass combines advanced material science with precision engineering to deliver exceptional protection and clarity for displays. The best solutions balance three critical properties:

-

Mechanical Strength – Chemically strengthened glass achieves 800+ MPa surface compression through ion exchange, enabling thin 0.3-1.1mm profiles that survive 1.5m drops

-

Optical Performance – Premium grades maintain >92% light transmission with <0.5% haze, while anti-reflective coatings reduce glare to <1.5%

-

Functional Enhancements – Optional treatments add anti-fingerprint, anti-microbial, or anti-glare properties

Manufacturing breakthroughs enable these capabilities:

• Down-draw process produces ultra-flat glass with ±0.03mm thickness tolerance

• Laser cutting creates precise edges that minimize microcracks

• In-line optical inspection ensures defect-free surfaces

From smartphone screens to automotive displays, understanding these core properties and processes helps engineers select the optimal cover glass solution.

Electronic Cover Glass: The Complete Engineering Guide to Materials and Manufacturing

Introduction to Modern Cover Glass Technology

Electronic cover glass has evolved from simple protection to a sophisticated display component that actively enhances device performance. Today’s solutions combine cutting-edge material science with precision manufacturing to meet the demanding requirements of smartphones, tablets, automotive displays, and emerging flexible electronics.

Core Material Properties of High-Performance Cover Glass

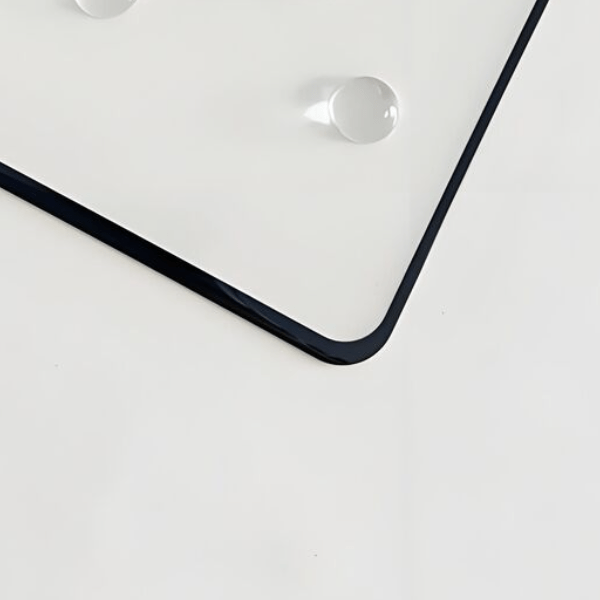

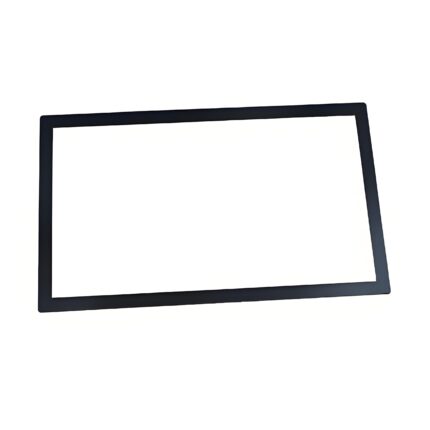

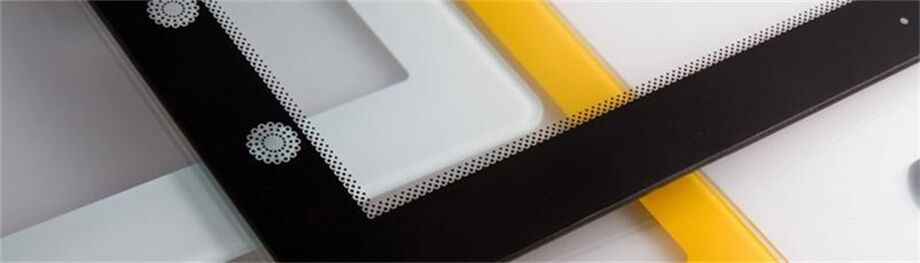

Silk screen print

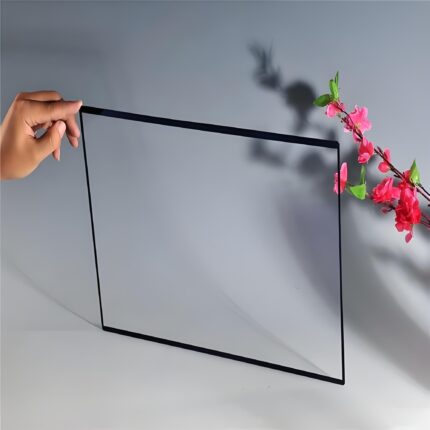

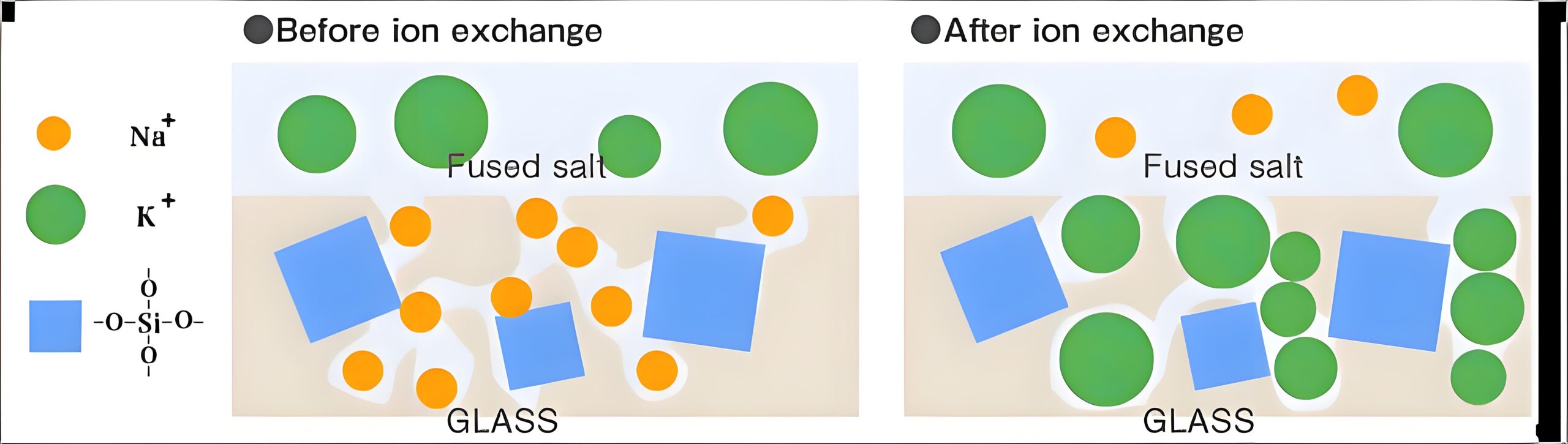

What’s chemical strengthened?

Mechanical Durability Characteristics

The foundation of quality electronic cover glass lies in its structural integrity:

-

Chemical Strengthening: Through potassium-for-sodium ion exchange, creating surface compression exceeding 800 MPa

-

Flexural Strength: Ranging from 500-900 MPa depending on formulation

-

Thickness Options: From ultra-thin 0.3mm for mobiles to rugged 2.0mm for industrial use

-

Scratch Resistance: 6H-9H pencil hardness ratings

Optical Performance Metrics

Superior visual clarity is achieved through:

-

Light Transmission: 92-95% across visible spectrum

-

Haze Levels: <0.5% for crystal-clear viewing

-

Reflectivity: Reduced to <1.5% with anti-reflective coatings

-

Color Neutrality: ΔE <1.0 for accurate color reproduction

Advanced Functional Properties

Optional enhancements include:

-

Oleophobic Coatings: Fingerprint resistance

-

Anti-Microbial Surfaces: Silver-ion infused layers

-

UV Protection: 99%+ blocking for outdoor displays

-

EMI Shielding: Conductive oxide layers

Cutting-Edge Manufacturing Processes

Glass Formation Techniques

Down-Draw Manufacturing

-

Produces pristine surfaces with Ra <0.5nm roughness

-

Maintains ±0.03mm thickness tolerances

-

Enables widths up to 3 meters for large-format applications

Float Glass Alternatives

-

Cost-effective for standard applications

-

Suitable for thicker glass requirements

-

Good optical quality with proper processing

Precision Fabrication Methods

Laser Cutting Advantages:

-

Kerf widths as narrow as 20μm

-

Minimal microcrack formation

-

Complex contour capabilities

CNC Grinding Benefits:

-

Excellent edge strength retention

-

Tight dimensional control

-

Suitable for prototype development

Quality Assurance Systems

-

Automated Optical Inspection: Detects sub-micron defects

-

Stress Pattern Analysis: Verifies chemical strengthening

-

Environmental Testing: Thermal cycling, humidity exposure

Application-Specific Solutions

Mobile Device Cover Glass

-

0.3-0.7mm thickness for slim profiles

-

3D formed edges for bezel-less designs

-

Under-display compatibility for cameras/sensors

Automotive Display Requirements

-

Vibration-resistant formulations

-

Heated glass options for defrosting

-

Sunlight-readable treatments

Industrial and Medical Applications

-

Chemical-resistant surfaces

-

Sterilization-compatible materials

-

Enhanced durability for harsh environments

Selection Criteria for Design Engineers

Key Decision Factors

-

Environmental Conditions: Temperature range, UV exposure, chemical contact

-

Optical Requirements: Transmission needs, glare control, color accuracy

-

Mechanical Demands: Impact resistance, scratch protection, flexibility

-

Special Features: Touch compatibility, integrated sensors, privacy filters

Specification Checklist

-

Material Composition: Aluminosilicate, soda lime, or hybrid

-

Thickness Profile: Standard or custom options

-

Surface Treatments: AR, AF, AG, or specialty coatings

-

Edge Work Specifications: Polished, ground, or laser-cut

-

Quality Certifications: Industry-standard testing results

Emerging Trends and Future Developments

Material Innovations

-

Self-Healing Glass: Microcapsule-based scratch repair

-

Dynamic Properties: Adjustable stiffness or opacity

-

Nanocomposite Blends: Enhanced strength-to-weight ratios

Manufacturing Advancements

-

Roll-to-Roll Processing: For flexible glass production

-

Digital Twin Integration: Real-time quality monitoring

-

AI-Optimized Cutting: Reduced material waste

Application Expansion

-

Foldable Displays: Ultra-thin flexible solutions

-

AR/VR Devices: Ultra-low reflectivity requirements

-

Smart Surfaces: Integrated touch and haptic feedback

Conclusion: Selecting the Optimal Cover Glass Solution

Choosing the right electronic cover glass requires careful consideration of both current needs and future requirements. By understanding the material properties, manufacturing processes, and application-specific demands, engineers can specify cover glass solutions that deliver:

-

Enhanced Device Performance: Through optimized optical and mechanical properties

-

Improved Durability: Extending product lifespan

-

Superior User Experience: With advanced functional features

As display technologies continue to evolve, cover glass innovations will play an increasingly vital role in enabling next-generation electronic devices.