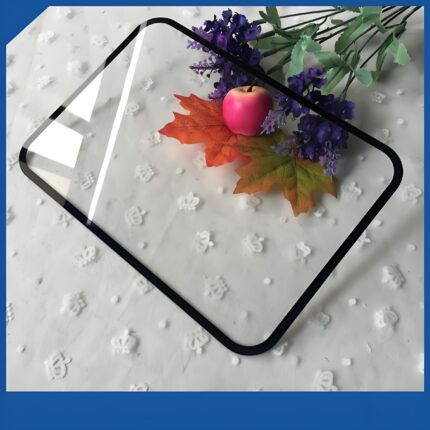

Custom UTG Cover Glass: Revolutionizing Flexible Display Technology

Our custom UTG cover glass transforms flexible device possibilities. We engineer ultra-thin glass that bends without breaking, maintains crystal clarity, and withstands 200,000+ folds. Perfect for foldable phones, wearables, and innovative displays. Choose from thicknesses 30-200μm with custom coatings and precise cutouts. Let’s create your revolutionary display solution together.

The Art and Science of Ultra-Thin UTG Cover Glass Innovation

When we first started experimenting with ultra-thin glass (UTG), we quickly realized we weren’t just working with another material – we were handling something that behaves more like a delicate fabric than traditional glass. Our journey with UTG began seven years ago, and what we’ve learned since then has completely transformed how we approach flexible display solutions. The magic isn’t just in making glass thin; it’s in maintaining its essential glass-like properties while achieving unprecedented flexibility.

I remember our first breakthrough moment – watching a 100-micron sheet of glass bend to a 3mm radius without fracturing. That was when we knew we were onto something special. Since then, we’ve refined our processes to achieve even more remarkable results, developing handling techniques that prevent the micro-cracks and edge defects that often plague UTG production. Our team has become so adept at working with this material that we can now consistently produce glass that’s thinner than a human hair yet stronger than many metals pound for pound.

Precision Engineering for Real-World Applications

Creating UTG that actually performs in consumer devices requires solving problems that don’t exist with conventional glass. The manufacturing process demands completely different thinking – from specialized handling systems that prevent surface damage to custom-designed strengthening processes that work at microscopic scales. We’ve developed proprietary equipment that gently guides the glass through production without compromising its structural integrity.

The chemical strengthening process presented particular challenges at these thicknesses. Traditional methods simply didn’t work, so we had to reinvent the process from the ground up. What we developed is a modified ion-exchange technique that creates deeper compression layers relative to the material thickness, resulting in glass that can withstand repeated folding while maintaining its scratch resistance and optical clarity. Our testing shows that our UTG can survive over 200,000 folding cycles at a 2mm radius – far exceeding most industry requirements.

Unmatched Customization Capabilities

What really sets our UTG apart is how we tailor it to specific applications. We don’t just make thin glass – we engineer solutions for particular devices and use cases. For a recent foldable smartphone project, we developed a specialized edge treatment that prevents cracking in the hinge area. For a wearable medical device, we created a UTG variant with enhanced chemical resistance to withstand sterilization procedures.

Our coating capabilities include anti-reflective treatments that maintain effectiveness even when the glass is flexed, oleophobic coatings that survive repeated cleaning, and even transparent conductive layers for touch functionality. We can work with thicknesses from 30 to 200 microns, creating solutions that balance flexibility with durability based on your specific needs. The cutting process uses laser systems that create clean edges without micro-cracks, ensuring the glass maintains its strength throughout its lifetime.

Technical Specifications

| Parameter | Specifications | Testing Method |

|---|---|---|

| Thickness Range | 30-200 μm | Laser measurement |

| Minimum Bend Radius | < 2 mm | Mandrel test |

| Folding Endurance | > 200,000 cycles | Industry-fold test |

| Surface Hardness | ≥ 6 Mohs | Scratch test |

| Optical Transmittance | > 91% (@550nm) | Spectrophotometer |

| Surface Roughness | < 0.5 nm | AFM measurement |

| Thermal Stability | -40°C to 150°C | Environmental testing |

| Chemical Resistance | Class 5 (acid/alkali) | Chemical exposure test |

| Compression Stress | > 800 MPa | Surface stress measurement |

| Density | 2.38 g/cm³ | Gravimetric analysis |

Application-Specific Solutions

Foldable Smartphones: Our UTG provides the perfect combination of flexibility and durability for modern foldable devices. We’ve developed specialized solutions that reduce visible creasing and prevent damage in the hinge area, extending the device’s lifespan while maintaining premium aesthetics.

Wearable Technology: For smartwatches and fitness trackers, we create UTG that’s thin enough for comfort yet durable enough for daily wear. Our solutions include curved variants that conform to wrist contours and special coatings that enhance visibility in various lighting conditions.

Flexible Displays: We’re working with display manufacturers to develop UTG that serves as both cover material and substrate for flexible OLEDs. Our glass provides superior barrier properties compared to polymer solutions, extending display lifespan while maintaining flexibility.

Automotive Interfaces: For curved automotive displays, our UTG offers excellent optical properties and durability while enabling designs that integrate seamlessly into modern vehicle interiors. We develop solutions that meet automotive temperature and reliability standards.

Why Choose Our UTG Solutions?

The difference comes down to experience and approach. We’ve been working with UTG since it was just a laboratory curiosity, and we’ve solved the practical problems that come with manufacturing it at scale. Our team understands not just how to make UTG, but how to make it work in real devices under real-world conditions.

We maintain strict quality controls throughout the manufacturing process, with multiple inspection points that ensure every piece meets our exacting standards. Our statistical process control systems monitor critical parameters in real-time, allowing us to maintain consistency across production runs. Whether you need prototypes for concept validation or high-volume production, we have the expertise and capacity to meet your requirements.

Partner With Us

Developing successful UTG-based products requires more than just a supplier – it requires a technical partner who understands both the material and its applications. Our engineering team works closely with clients throughout the development process, providing design guidance, prototyping support, and manufacturing expertise. We understand the unique challenges of working with UTG and can help you avoid common pitfalls while optimizing your design for manufacturability and performance.

Contact us today to discuss your UTG needs and receive samples tailored to your specific application. Let’s work together to create the next generation of flexible devices.