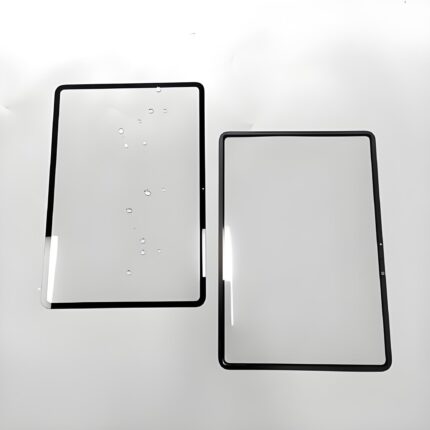

Custom UTG Cover Glass for Advanced Electronic Devices

Our custom UTG cover glass enables revolutionary flexible electronics with exceptional clarity and durability. Engineered for foldable phones, wearables, and innovative displays, it offers superior flexibility (2mm bend radius), hardness (6+ Mohs), and optical performance (>91% transmittance). Withstand 200,000+ folds. Custom coatings, cutouts, and shapes available. Partner with us for cutting-edge solutions.

The Future is Flexible: Transforming Electronics with Ultra-Thin UTG Cover Glass

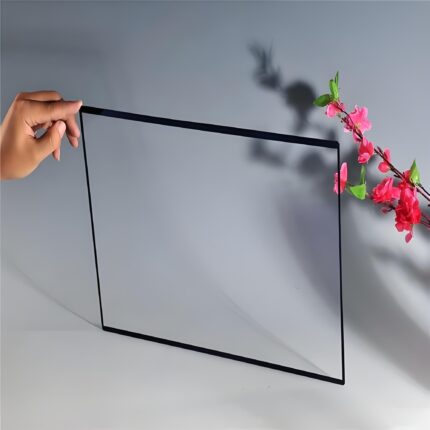

Remember when “flexible display” sounded like science fiction? Today, it’s not just reality – it’s revolutionizing how we interact with our devices. At the heart of this transformation lies Ultra-Thin Glass (UTG), a material that’s changing everything from smartphones to wearable technology. Our custom UTG cover glass represents the pinnacle of this innovation, offering manufacturers unprecedented opportunities to create devices that bend, fold, and flex without compromising on durability or clarity.

What makes our UTG different isn’t just its thinness – it’s our understanding of how this material behaves in real-world applications. We’ve spent years perfecting the art of working with glass thinner than human hair, developing specialized handling techniques and manufacturing processes that ensure every piece meets exacting standards. Our team doesn’t just produce glass; we create possibilities for product designers who want to push boundaries and create truly innovative electronic devices.

Precision Engineering for Exceptional Performance

Creating UTG that performs reliably in consumer electronics requires addressing unique challenges that simply don’t exist with traditional glass. The manufacturing process begins with specially formulated glass compositions that maintain their structural integrity even at minimal thicknesses. Our proprietary thinning process creates surfaces so smooth they require minimal additional processing, yet we still subject every sheet to precision polishing to ensure optimal optical performance.

The real magic happens in our chemical strengthening process, which we’ve optimized specifically for ultra-thin applications. Where conventional strengthening methods might cause distortion or warping at these thicknesses, our technique creates uniform compressive stress that provides remarkable durability without compromising flexibility. We’ve developed specialized testing equipment that simulates thousands of folding cycles under various environmental conditions, ensuring our UTG can withstand the rigors of daily use in foldable phones and other flexible devices.

Unmatched Customization Capabilities

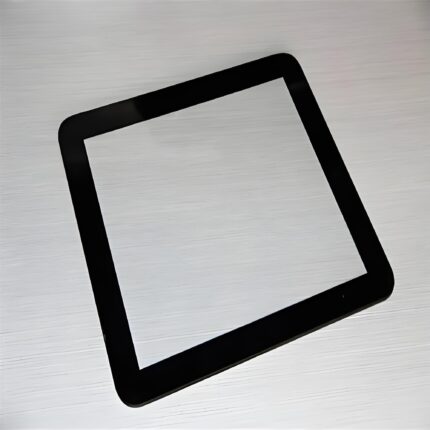

Your innovative device deserves cover glass that matches your vision perfectly. Our customization options extend far beyond simple cutting to shape. We work with you to develop solutions specific to your product’s requirements, whether you need custom cutouts for sensors and cameras, specialized edge treatments for seamless assembly, or unique surface treatments for enhanced functionality.

Our technical team excels at solving complex design challenges, such as integrating UTG with other materials or creating hybrid solutions that combine flexibility in some areas with rigidity in others. We can apply various functional coatings including anti-reflective treatments, anti-fingerprint coatings, and even transparent conductive layers for touch functionality. The bonding processes we’ve developed allow for seamless integration with displays and other components, ensuring perfect performance in the final product.

Technical Specifications and Performance Data

| Parameter | Specifications | Testing Method |

|---|---|---|

| Thickness Range | 30μm – 200μm | Laser measurement |

| Minimum Bend Radius | < 2mm | Mandrel test |

| Folding Endurance | > 200,000 cycles (2mm radius) | Industry-fold test |

| Surface Hardness | ≥ 6 Mohs | Scratch test |

| Optical Transmittance | > 91% (@550nm) | Spectrophotometer |

| Roughness (Ra) | < 0.5nm | AFM measurement |

| Thermal Stability | -40°C to 150°C | Environmental chamber |

| Chemical Strength | Resists acids and alkalis | Chemical exposure test |

| Compression Stress | > 800 MPa | Surface stress measurement |

Application-Specific Solutions

Foldable Smartphones: Our UTG provides the perfect combination of flexibility and durability for hinge mechanisms and folding displays. We’ve developed specialized edge deletion techniques that prevent cracking in high-stress areas and coatings that reduce visible creasing in the folded state.

Wearable Technology: For smartwatches and fitness trackers, our ultra-thin glass reduces weight and improves comfort while maintaining the premium feel of glass. We can create curved solutions that conform to wrist contours and special coatings that enhance visibility in various lighting conditions.

Flexible Tablets and E-Readers: Larger format UTG requires even more precise manufacturing control. Our processes maintain perfect flatness across large surfaces while still allowing the flexibility needed for innovative form factors and usage scenarios.

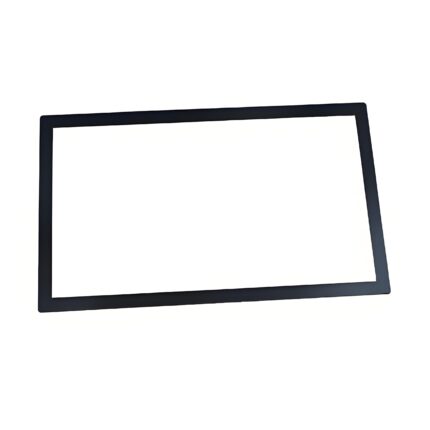

Automotive Displays: For curved automotive displays, our UTG offers excellent optical properties and durability while enabling designs that integrate seamlessly into modern vehicle interiors. We develop solutions that meet automotive temperature and reliability standards.

Partnering for Success

Developing successful UTG-based products requires more than just supplying materials – it requires technical partnership throughout the development process. Our engineers work closely with your team from concept through production, providing design guidance, prototyping support, and manufacturing expertise. We understand the unique challenges of working with UTG and can help you avoid common pitfalls while optimizing your design for manufacturability and performance.

We maintain strict confidentiality protocols to protect your intellectual property and offer flexible engagement models from basic supply to full co-development partnerships. Our quality systems ensure consistent performance across production runs, with comprehensive documentation and traceability for every batch produced.

Experience the Difference

The true test of UTG quality isn’t in laboratory measurements – it’s in how it performs in your customers’ hands. That’s why we invite you to test our materials in your specific application. Contact us today to discuss your requirements and receive samples tailored to your needs. Our technical team will work with you to develop the perfect UTG solution for your next groundbreaking electronic device.

Discover why leading electronics manufacturers choose our custom UTG cover glass for their most innovative products. Let’s create the future of flexible electronics together.