Custom Silk Screen Printed Glass for OLED Displays & Smart Devices

Premium Silk Screen Printed Glass for High-End Electronics

Looking for durable, precision-printed glass for your OLED displays or smart devices? Our silk screen printed glass delivers crisp graphics and long-lasting performance.

Why manufacturers choose us:

✔ Ultra-fine details (down to 50µm resolution)

✔ Scratch-resistant ceramic & UV inks

✔ Custom designs for displays, touch panels & wearables

✔ Cost-effective for mass production

Used in:

-

Smartphone/tablet borders & logos

-

Automotive dash displays

-

Smartwatch faces & control panels

Get superior print quality without compromising durability – request your samples today!

Custom Silk Screen Printed Glass for OLED Displays & Smart Devices

1. Introduction

In today’s competitive electronics market, silk screen printed glass has become a critical component for high-performance OLED displays and smart devices. Whether you’re manufacturing smartphones, wearables, or automotive displays, custom silk screen printing ensures precise graphics, durable coatings, and enhanced functionality.

This guide explores why silk screen printed glass is the preferred choice for manufacturers, detailing its benefits, applications, and how it outperforms alternative printing methods.

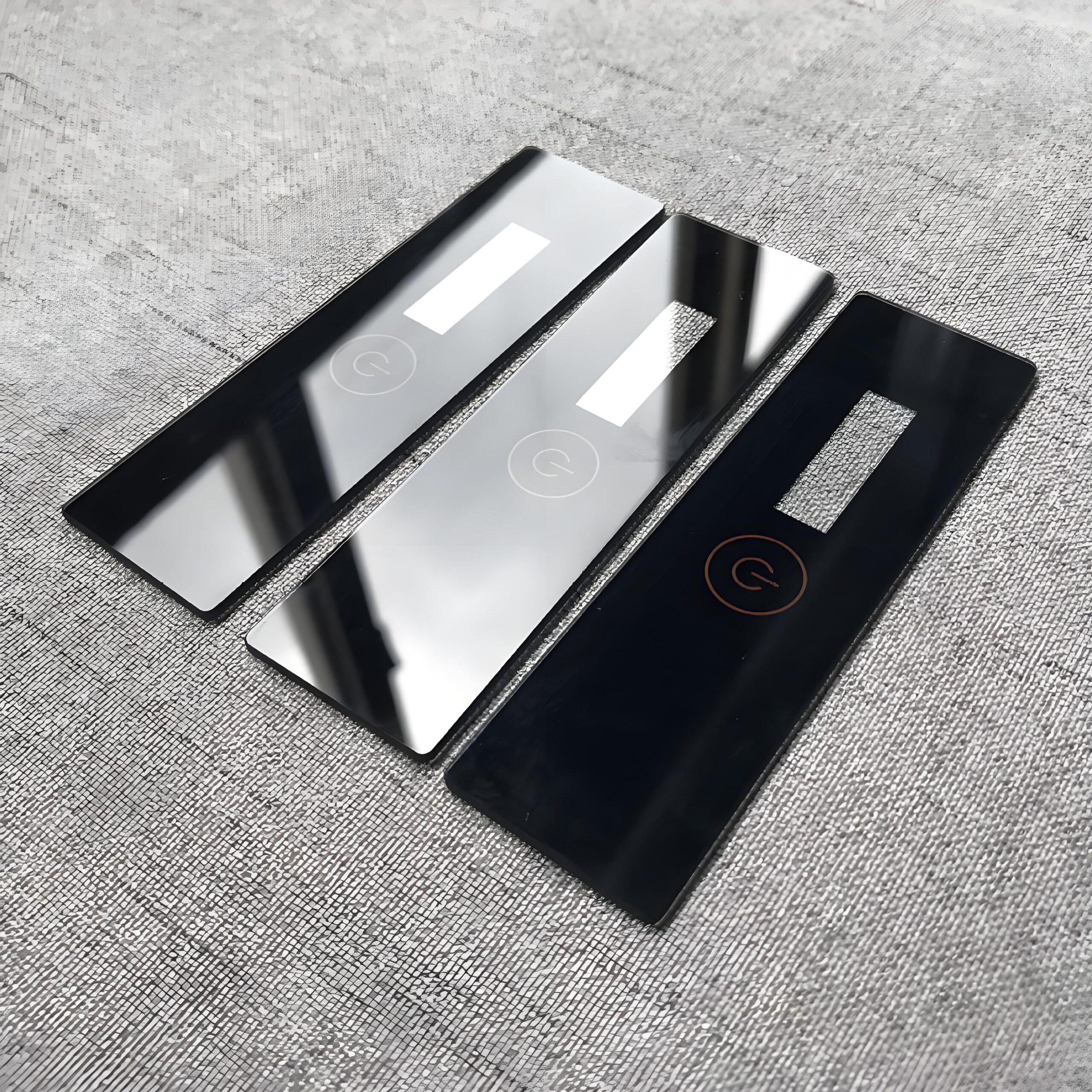

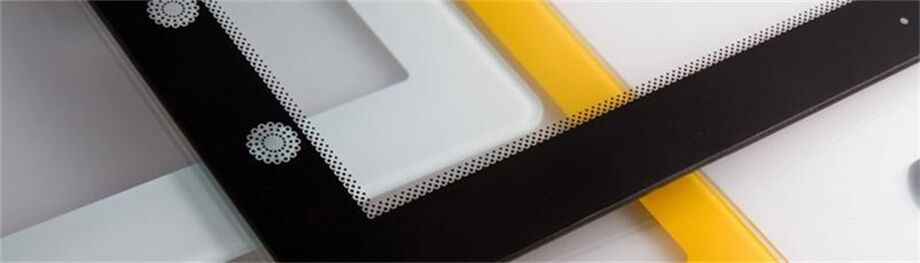

2. What is Silk Screen Printed Glass?

Silk screen printed glass is a specialized manufacturing process where ink or coatings are applied through a fine mesh stencil onto glass surfaces. This technique allows for:

-

High-resolution patterns (logos, borders, touch sensor lines)

-

Durable, scratch-resistant layers (UV-cured inks, ceramic frits)

-

Custom designs (branding, anti-glare borders, decorative elements)

Unlike digital printing, silk screen printing offers superior adhesion and longevity, making it ideal for OLED displays, smart mirrors, and touch panels.

3. Key Benefits of Silk Screen Printed Glass

3.1 Superior Durability

-

Withstands extreme temperatures, moisture, and UV exposure

-

Resistant to scratches and chemical wear (perfect for automotive displays)

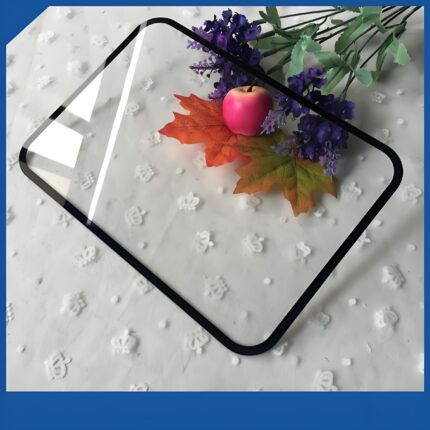

3.2 Precision & Customization

-

Supports fine details (down to 50µm line width)

-

Compatible with ITO-coated glass, tempered glass, and flexible substrates

3.3 Cost-Effective for Mass Production

-

Faster than laser etching or digital printing

-

Lower per-unit cost for large batches

4. Applications in OLED Displays & Smart Devices

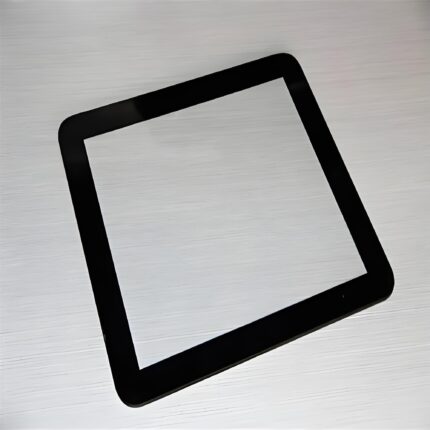

4.1 Smartphones & Tablets

-

Used for black borders, logos, and touch sensor lines

-

Improves aesthetics while reducing light leakage

4.2 Automotive Displays

-

Heat-resistant silk screen printed glass for dashboards and HUDs

-

Anti-glare coatings for better visibility

4.3 Wearable Technology

-

Custom designs for smartwatch faces and fitness trackers

-

Thin, lightweight printing that doesn’t affect flexibility

5. Why Choose Silk Screen Over Other Printing Methods?

| Feature | Silk Screen Printing | Digital Printing | Laser Etching |

|---|---|---|---|

| Durability | Excellent | Moderate | High |

| Cost (High Volume) | Low | High | Very High |

| Precision | 50µm+ | 20µm+ | 10µm+ |

| Material Compatibility | Glass, PET, Ceramic | Limited | Glass Only |

Conclusion: For high-volume, durable, and cost-effective printing, silk screen printed glass remains the top choice.

6. Future Trends in Silk Screen Printing for Electronics

As OLED and flexible displays evolve, silk screen printing is adapting with:

✔ Nano-inks for finer conductive traces

✔ Hybrid printing (combining silk screen with digital for complex designs)

✔ Eco-friendly UV inks for sustainable manufacturing

Get Your Custom Silk Screen Printed Glass Today!

Whether you need anti-reflective borders, branding, or functional coatings, our silk screen printed glass solutions meet the highest industry standards.

Contact us for samples and technical specifications!