Custom Cover Glass Solutions for Your Unique Display Needs

Premium Custom Cover Glass for Precision Displays

Our Custom Cover Glass solutions are engineered to your exact specifications, delivering superior protection and clarity for industrial, medical, and consumer electronics.

Key Benefits:

✔ Precision-Cut – Laser-cut to ±0.1mm tolerances

✔ Extreme Durability – Chemically strengthened, scratch-resistant (9H hardness)

✔ Optimal Clarity – Anti-glare, anti-fingerprint, and high-transparency options

✔ Wide Compatibility – Fits touchscreens, HMIs, medical devices, and more

Available in soda-lime, aluminosilicate, or sapphire glass with custom coatings, edge treatments, and sensor integrations.

Custom Cover Glass Solutions for Your Unique Display Needs

Introduction to Custom Cover Glass

In today’s competitive electronics market, having the right Custom Cover Glass can make all the difference in product performance and durability. Whether you’re designing medical devices, industrial equipment, or consumer electronics, our Custom Cover Glass solutions are engineered to meet your exact specifications.

Unlike off-the-shelf solutions, our Custom Cover Glass is tailored to fit your display requirements perfectly—ensuring optimal clarity, protection, and functionality.

Why Choose Custom Cover Glass?

1. Precision Engineering for Perfect Fit

Every display has unique dimensions, and a one-size-fits-all approach simply doesn’t work. Our Custom Cover Glass is manufactured using advanced laser cutting and CNC machining to ensure:

-

Exact dimensions (tolerances as tight as ±0.1mm)

-

Seamless integration with touch panels and displays

-

Custom edge treatments (polished, beveled, or drilled)

2. Enhanced Durability for Demanding Environments

Standard glass may crack under stress, but our Custom Cover Glass is chemically strengthened or tempered for superior resistance against:

-

Scratches (up to 9H hardness)

-

Impact drops (tested to MIL-STD-810G standards)

-

Extreme temperatures (-30°C to 150°C operational range)

3. Optical Clarity & Anti-Glare Options

Poor visibility can ruin user experience. We offer:

-

High-transparency (>92% light transmission) glass

-

Anti-reflective (AR) coatings for sunlight readability

-

Matte finishes to reduce fingerprint smudges

Applications of Custom Cover Glass

Industrial Control Panels

Harsh factory environments demand rugged protection. Our Custom Cover Glass is used in:

-

Machine HMI interfaces

-

Outdoor kiosks

-

Oil & gas monitoring systems

Medical Devices

Sterilization and clarity are critical. We supply:

-

Autoclave-safe cover glass for surgical displays

-

Antimicrobial-coated glass for hygiene compliance

Consumer Electronics

From smartwatches to tablets, our Custom Cover Glass enhances:

-

Touch responsiveness

-

Aesthetic appeal (colored borders, logos)

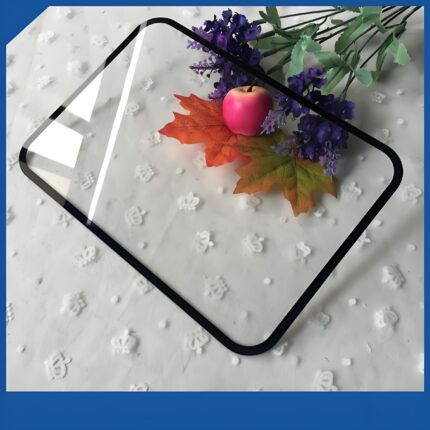

Customization Options

1. Material Choices

-

Soda-lime glass (cost-effective for indoor use)

-

Aluminosilicate glass (ultra-tough for mobile devices)

-

Sapphire glass (scratch-proof for luxury products)

2. Surface Treatments

-

Oleophobic coating (repels fingerprints)

-

Anti-fog layers (ideal for medical and automotive)

3. Special Features

-

Embedded sensors (force touch, temperature)

-

Privacy filters (narrow viewing angles)

Quality Assurance & Testing

Every Custom Cover Glass undergoes rigorous checks:

✔ Optical inspection (zero defects allowed)

✔ Drop testing (1.5m onto steel, 10x cycles)

✔ Chemical resistance tests (alcohol, disinfectants)

Get Your Custom Cover Glass Quote Today

Ready to upgrade your displays with precision-engineered Custom Cover Glass? Contact our engineers for:

📌 Free design consultation

📌 Prototyping in 10 days

📌 Volume production with competitive MOQs

Request a sample and see why leading brands trust our Custom Cover Glass solutions for their most demanding applications.