Custom Camera Glass – Laser Cut & Silk Screen Printed to Spec

Precision Laser-Cut Camera Glass with Silk Screen Printing

Need custom camera protection that fits perfectly? Our camera glass combines laser precision with durable silk screen printing for OEM-quality results.

Key Features:

✔ Laser-cut to exact specs – ±0.05mm tolerance for perfect fit

✔ Crisp silk screen printing – logos, markings that won’t fade

✔ Multiple material options – from 0.3mm ultra-thin to 2.0mm rugged

✔ Specialty coatings available – anti-reflective, anti-fingerprint

Custom Camera Glass – Laser Cut & Silk Screen Printed to Your Exact Specifications

Precision-Engineered Camera Glass for Flawless Imaging

Our custom camera glass solutions combine laser cutting and silk screen printing to deliver optically superior protection tailored to your exact requirements. Whether for smartphones, security cameras, automotive sensors, or medical imaging devices, each piece of camera glass undergoes meticulous fabrication to ensure perfect fit, clarity, and durability.

Unlike mass-produced alternatives, our camera glass is:

✔ Laser-cut for micron-level precision (±0.05mm tolerance)

✔ Silk screen printed with permanent, high-resolution markings

✔ Chemically strengthened for 6-8x greater impact resistance

✔ Customizable in shape, thickness, and coatings

Why Choose Our Custom Camera Glass?

1. Laser-Cut Precision for Perfect Fit

-

CNC laser cutting ensures exact dimensions for:

-

Smartphone camera modules

-

Multi-lens array cutouts

-

Irregular-shaped sensor windows

-

-

Clean, chip-free edges prevent light refraction

-

Supports complex geometries (circles, rectangles, notches)

2. High-Durability Silk Screen Printing

-

Permanent markings that won’t fade or scratch off

-

Resolution down to 0.1mm line width for crisp logos/text

-

Available in multiple colors (black, white, metallic)

-

EMI-shielding ink options for sensor applications

3. Superior Optical Performance

-

92% light transmittance for minimal image distortion

-

Anti-reflective (AR) coating options

-

Oleophobic layers to repel fingerprints

Technical Specifications

| Parameter | Specifications |

|---|---|

| Material | Aluminosilicate/Soda Lime Glass |

| Thickness | 0.3mm – 2.0mm (±0.05mm) |

| Laser Cut Tolerance | ±0.05mm |

| Printing Resolution | 0.1mm minimum line width |

| Hardness | 7H-9H (Pencil Test) |

| Temperature Resistance | -30°C to 150°C |

Applications Across Industries

1. Smartphones & Consumer Electronics

-

Front/rear camera glass with brand logos

-

Under-display camera cutouts

-

IR filter windows for facial recognition

2. Automotive & Surveillance

-

Dashcam lens protection

-

ADAS sensor windows

-

License plate camera covers

3. Medical & Industrial Imaging

-

Endoscope lens covers

-

Barcode scanner windows

-

Machine vision camera ports

Customization Options

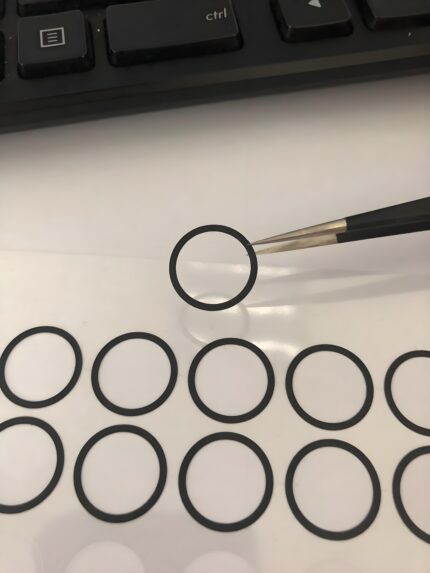

1. Laser Cutting Variations

-

Straight or curved edges

-

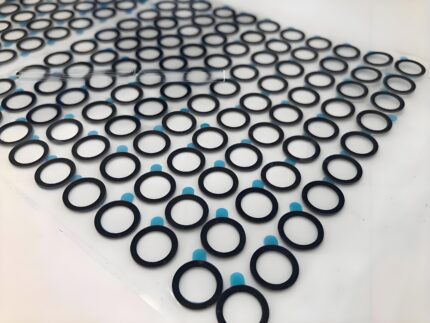

Round, rectangular, or custom shapes

-

Multi-hole patterns for array cameras

2. Silk Screen Printing Choices

-

Brand logos, alignment marks, or text

-

Matte/gloss finishes

-

Conductive traces for touch functionality

3. Additional Enhancements

-

Anti-glare/anti-fingerprint coatings

-

IR-cut filters for night vision

-

Black masking around edges

Manufacturing Process

1. Precision Laser Cutting

-

Computer-controlled CO₂ or UV lasers

-

No micro-cracks or thermal stress

-

Deburring/polishing for smooth edges

2. Silk Screen Printing

-

High-temp ceramic inks (up to 800°C resistant)

-

Multi-layer printing for opacity

-

UV-cured for instant drying

3. Quality Verification

-

Optical comparators verify dimensions

-

Microscopic print inspection

-

Sample testing to MIL-STD-810G

Frequently Asked Questions

Q: What’s the minimum order quantity?

A: Prototypes start at 10pcs; production MOQ 1,000pcs.

Q: Can you replicate existing camera glass designs?

A: Yes – send samples/blueprints for exact duplication.

Q: How durable is the silk screen printing?

A: Withstands 500+ wipe cycles and UV exposure.