Corning Gorilla Glass Cover Panels Scratch-Resistant, Durable Cover Glass for Touchscreens & Displays

Corning Gorilla Glass Cover Panels

Engineered for exceptional durability and clarity, Corning Gorilla Glass features ion-exchange strengthening to resist scratches, impacts, and daily wear. With optional AR coatings reducing reflectance to ≤1.5% and oleophobic protection against fingerprints, it ensures superior optical performance for smartphones, automotive displays, industrial HMIs, and medical devices. Custom sizes, thicknesses (0.4–2.0mm), and coatings available. Trusted by global brands for reliability and innovation. Contact us for technical support and samples.

Engineered for Resilience: Why Gorilla Glass Cover is the Industry Standard for Premium Cover Panels

In an era where sleek, durable, and responsive touch interfaces define user experiences, the choice of cover glass can make or break a product. Corning Gorilla Glass has long been the gold standard for high-performance electronic displays, and for good reason. Its unique combination of hardness, scratch resistance, and optical clarity makes it the ideal solution for devices subjected to daily wear and tear—from smartphones and tablets to automotive infotainment systems and industrial HMIs.

What sets Gorilla Glass apart is its ion-exchange manufacturing process. In this proprietary technique, glass substrates are immersed in a molten salt bath, where smaller sodium ions in the glass are replaced by larger potassium ions from the bath. This creates a deeply compressed surface layer, resulting in exceptional resistance to scratches, drops, and impacts. Whether you’re designing consumer electronics or mission-critical industrial equipment, Gorilla Glass ensures that your display remains intact, readable, and responsive under pressure.

Technical Specifications: Built for Performance and Reliability

Gorilla Glass is more than just tough—it’s a precision-engineered material designed to meet the demands of modern applications. Below, we break down its key technical attributes, including optional anti-reflective (AR) and oleophobic coating enhancements.

Table: Gorilla Glass Standard and Enhanced Performance Metrics

| Parameter | Standard Gorilla Glass | Gorilla Glass with AR/Oleophobic Coating | Test Method |

|---|---|---|---|

| Vickers Hardness | 600–650 HV | 600–650 HV (substrate) | ISO 6507 |

| Surface Compressive Stress | ≥ 690 MPa | ≥ 690 MPa | Polarimetric SCALP |

| Transmittance (550 nm) | ≥ 91% | ≥ 94% with AR coating | ASTM D1003 |

| Reflectance | ~8% (uncoated) | ≤ 1.5% per side with AR coating | Spectral reflectance meter |

| Drop Resistance | Survives drops from 1.0–1.6 meters | Similar with proper coating integration | Field simulation tests |

| Scratch Resistance | Resists scratches from keys, knives | Enhanced with hardened coatings | Mohs hardness test |

| Chemical Durability | Resists solvents, acids, and alkalis | Resists fingerprints, sweat, and cleaners | ISO 12844 |

| Thickness Range | 0.4–2.0 mm | 0.5–2.0 mm | Laser micrometer |

| Oleophobic Performance | Standard oil repellency | > 110° contact angle | ASTM D5946 |

Key Advantages of Gorilla Glass Cover Panels

1. Superior Damage Resistance

Gorilla Glass’s ion-exchange treatment creates a surface that is remarkably resistant to scratches, scuffs, and impact. This is critical not only for consumer devices like smartphones and laptops but also for industrial and automotive applications, where displays must withstand harsh environments, frequent contact, and potential mishandling.

2. Enhanced Optical Properties

While uncoated Gorilla Glass already offers high light transmittance, adding anti-reflective (AR) and anti-fingerprint (oleophobic) coatings takes performance to the next level. AR coatings reduce glare and reflections, making displays easier to read in bright sunlight or under strong indoor lighting. Oleophobic coatings repel oils and smudges, keeping screens cleaner with less frequent wiping.

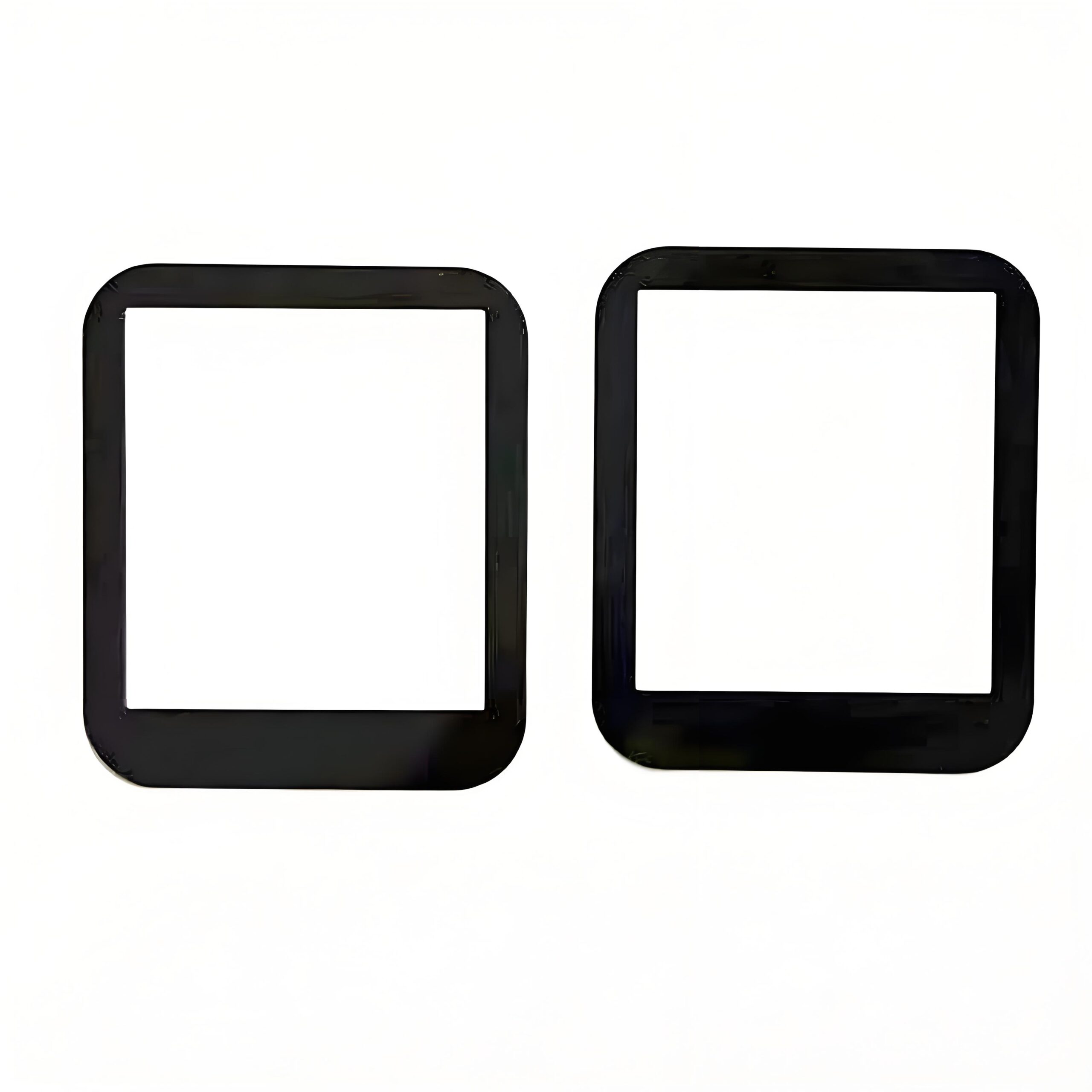

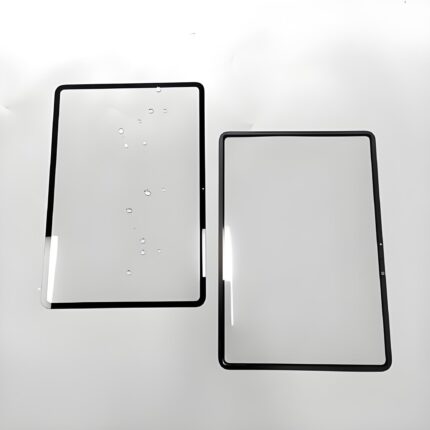

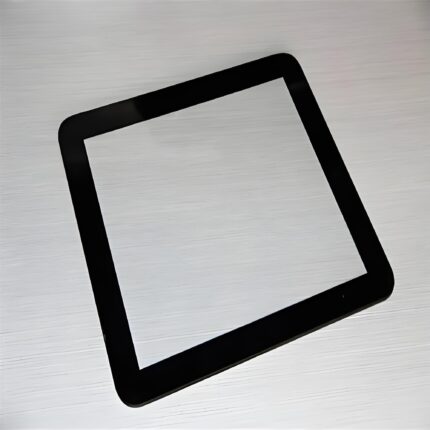

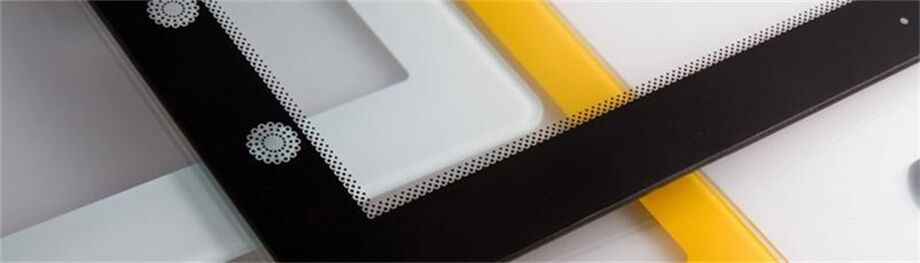

3. Design Flexibility

Gorilla Glass is available in a range of thicknesses and can be custom-cut, drilled, etched, and shaped to meet specific design requirements. It is also compatible with additional functional coatings, printing, and lamination processes, making it highly adaptable for innovative product designs.

4. Trusted Brand Recognition

Specifying Gorilla Glass isn’t just a technical decision—it’s a marketing advantage. End-users recognize and trust the Gorilla Glass name, associating it with quality, durability, and cutting-edge technology.

Applications Across Industries

-

Consumer Electronics: Smartphones, tablets, laptops, wearables

-

Automotive: Infotainment screens, instrument clusters, heads-up displays (HUDs)

-

Industrial: Human-machine interface (HMI) panels, kiosks, control systems

-

Medical: Diagnostic equipment, handheld devices, monitoring systems

-

Retail & Hospitality: POS systems, interactive signage, self-service terminals

Customization and Support

We work closely with clients to provide tailored Gorilla Glass solutions—whether you need custom geometries, specific coating stacks (AR, AG, AF), or additional strengthening. Our technical team supports you from prototyping to volume production, ensuring your displays are both high-performing and reliable.

Conclusion: A Material You Can Trust

When failure isn’t an option, Gorilla Glass delivers. It combines proven durability, optical excellence, and brand credibility—making it the clear choice for demanding cover glass applications.

Interested in testing Gorilla Glass for your project? Contact us for samples, technical data sheets, and design consultation.