Choosing the Right Cover Glass for Touchscreen and Display Applications

Choosing the Right Cover Glass for Touchscreen and Display Applications

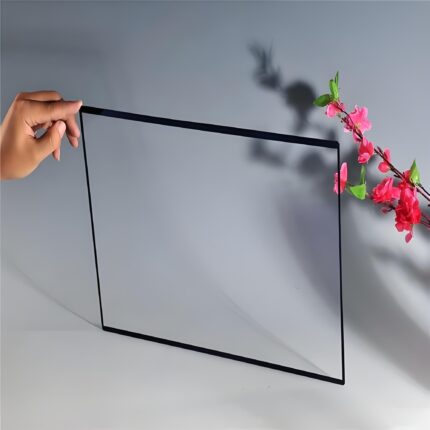

The perfect cover glass balances durability, clarity, and touch responsiveness for your specific device needs. For high-end smartphones, chemically strengthened aluminosilicate glass resists daily wear while maintaining razor-sharp visuals. Industrial displays often require thicker, tempered variants that withstand extreme conditions.

Consider these key factors: optical transparency (92%+ for premium displays), surface hardness (6H+ pencil hardness for scratch resistance), and compatibility with touch sensors. New innovations like anti-microbial coatings and self-healing surfaces are expanding possibilities across medical, automotive, and consumer electronics applications.

The Essential Guide to Selecting High-Performance Cover Glass for Modern Displays

Why Cover Glass Selection Matters More Than Ever

In today’s display-driven world, your choice of cover glass directly impacts:

-

User experience (touch sensitivity, visual clarity)

-

Product longevity (scratch and impact resistance)

-

Brand perception (premium feel and reliability)

From smartphones to industrial control panels, the right cover glass solution bridges the gap between protection and performance.

Cover Glass Materials: Choosing the Right Foundation

Premium Consumer Electronics Options

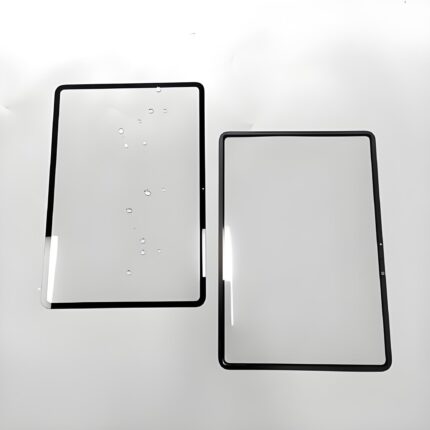

Chemically Strengthened Aluminosilicate Glass

-

Ideal for: Smartphones, tablets, wearables

-

Key benefits:

-

Maintains 92%+ optical clarity

-

Withstands 6H+ pencil hardness

-

Available in ultra-thin 0.3mm profiles

-

Sapphire Composite Solutions

-

Best for: Luxury watches, military displays

-

Advantages:

-

Near-diamond hardness (9H rating)

-

Superior chemical resistance

-

Long-term UV stability

-

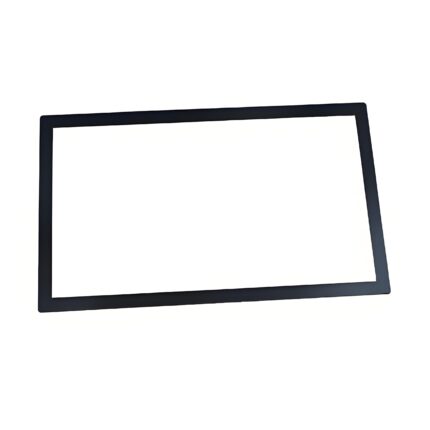

Industrial-Grade Solutions

Tempered Laminated Glass

-

Critical for: Automotive, medical, factory displays

-

Performance highlights:

-

5-10x thicker than consumer versions (2-5mm)

-

Built-in heating elements available

-

Impact-resistant interlayers

-

Technical Specifications You Can’t Compromise On

Optical Performance Benchmarks

-

Light transmission: 90-95% for most applications

-

Haze levels: <1% for premium displays

-

Reflectivity: <8% with AR coatings

Durability Standards

-

Drop test ratings: 1-3m survivability

-

Thermal cycling: -40°C to 85°C stability

-

Chemical resistance: Alcohol, cleaners, oils

Cutting-Edge Innovations Transforming Cover Glass

Surface Treatments Redefining Possibilities

Self-Healing Coatings

-

Microcapsule technology repairs minor scratches

-

Activated by heat or sunlight

-

Currently available in premium automotive displays

Anti-Microbial Solutions

-

Silver-ion infused surfaces

-

99% bacterial reduction

-

Medical and food industry applications

Structural Breakthroughs

3D Formed Glass

-

Enables true edge-to-edge displays

-

Allows for curved automotive dashboards

-

Reduces device bezels by up to 60%

Integrated Sensor Technology

-

Direct laser patterning of touch sensors

-

Eliminates separate touch layers

-

Improves optical performance

Practical Selection Guide for Engineers

Step 1: Define Your Application Requirements

-

Environmental conditions (indoor/outdoor)

-

Expected usage cycles

-

Safety certifications needed

Step 2: Material Shortlisting

-

Consumer vs. industrial grade

-

Flexibility requirements

-

Budget constraints

Step 3: Validate Performance

-

Request sample testing

-

Verify supplier certifications

-

Check real-world case studies

Installation and Maintenance Best Practices

Mounting Considerations

-

Adhesive selection: OCA vs. OCR

-

Stress management: Proper edge finishing

-

Alignment precision: <0.1mm tolerance

Long-Term Care

-

Recommended cleaning solutions

-

UV degradation monitoring

-

Scratch resistance over time

The Future of Cover Glass Technology

Emerging trends worth watching:

-

Electrochromic glass (adjustable transparency)

-

Energy-harvesting surfaces

-

AI-powered damage prediction