Chemical Strengthening in Screen-Printed Electronic Cover Glass

Chemically Strengthened Screen-Printed Cover Glass

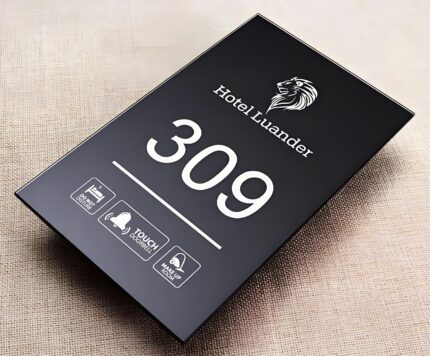

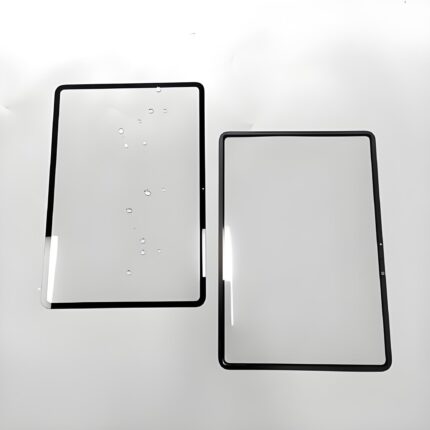

Aluminosilicate glass undergoes ion exchange in molten potassium nitrate, creating a deep compressive surface layer. This process significantly enhances impact and scratch resistance, maintaining optical clarity. Specially engineered for high-adhesion screen printing, it supports precise conductive and decorative inks while withstanding mechanical and thermal stresses. Ideal for consumer electronics, automotive displays, and industrial touch panels, it combines durability with design flexibility. Custom stress profiles (≥600 MPa compression, >40μm DOC) available to meet specific application requirements.

Chemical Strengthening in Screen-Printed Electronic Cover Glass: A Technical Overview

1 Introduction to Chemically Strengthened Cover Glass

If you’ve ever used a smartphone, you’ve interacted with cover glass. But not all glass is created equal. The journey from a fragile silica sheet to a damage-resistant component involves a fascinating process called chemical strengthening. For screen-printed electronic cover glass, this isn’t just an added bonus—it’s absolutely essential.

I remember visiting a manufacturing facility years ago and watching technicians handle pristine glass panels before they underwent strengthening. They treated each piece like a delicate artifact, which it was. Post-strengthening, that same glass could withstand pressures and impacts that would shatter ordinary glass. That transformation stuck with me.

Chemical strengthening through ion exchange doesn’t just make glass tougher; it enables the intricate screen-printing processes that apply conductive inks, decorative elements, and functional patterns onto the surface. Without this strength, the mechanical stresses during printing and everyday use would lead to micro-cracks and failure.

2 The Science Behind Chemical Strengthening

So how does it actually work? At its core, chemical strengthening is an ion exchange process. We submerge the glass—typically composed of aluminosilicate—into a molten salt bath, usually potassium nitrate (KNO₃), heated to around 400°C. Sodium ions (Na⁺) in the glass surface diffuse out, while larger potassium ions (K⁺) from the salt bath diffuse in.

This ion swap creates a compressive stress layer on the surface. The larger potassium ions cram themselves into spaces previously occupied by sodium ions, like trying to fit a bigger peg into a hole that’s just slightly too small. This crowding creates tremendous inward pressure, making it incredibly difficult for surface cracks to initiate or propagate.

The depth of this layer—what we call the depth of compression (DOC)—and the magnitude of the compressive stress are the two key parameters determining the final strength. For electronic cover glass, we typically aim for a compression stress of 600 MPa or higher and a DOC exceeding 40 micrometers. This isn’t just theoretical; I’ve seen stress measurements using surface stress meters show readings that would surprise anyone unfamiliar with the process.

3 Screen Printing on Strengthened Glass: A Delicate Dance

Screen printing on chemically strengthened glass isn’t as straightforward as printing on plastic or metal. The process demands careful consideration of the glass’s altered properties. I’ve worked with design engineers who initially struggled with adhesion issues until we optimized the process.

The compression layer, while fantastic for durability, presents a slightly different surface energy landscape. This affects how inks—especially conductive silver inks or dielectric inks—wet and adhere to the surface. We often need to adjust ink formulations with specific additives or employ surface treatments like plasma cleaning before printing to ensure optimal adhesion.

The thermal expansion mismatch between the glass substrate and the printed inks can’t be ignored either. During the curing process, which often involves heating to 120-150°C, different materials expand at different rates. If we don’t account for this, the resulting stresses can cause delamination or even micro-cracks in the worst cases. It’s a balancing act that requires experience and sometimes a bit of trial and error.

4 Performance Advantages in Real-World Applications

The marriage of chemical strengthening and screen printing creates cover glass that stands up to real-world abuse. I’ve seen testing labs where devices undergo repeated drops from specified heights onto rough surfaces. The difference between strengthened and non-strengthened glass isn’t subtle—it’s the difference between a functioning device and a shattered screen.

This durability isn’t just about drop resistance. For devices with touch functionality, the cover glass must withstand millions of touch interactions without degrading. The hardness imparted by chemical strengthening makes the surface highly resistant to scratching from everyday objects like keys or coins sitting in the same pocket.

Perhaps the most underappreciated advantage is how the strengthening process maintains the optical clarity essential for displays. Unlike tempering, which can cause slight distortions, chemical strengthening preserves the glass’s pristine optical properties. This is non-negotiable for high-resolution displays where every pixel needs to be perfectly clear.

5 Manufacturing Considerations and Challenges

Scaling up production of screen-printed strengthened glass presents unique challenges. The ion exchange process itself requires precise control of bath temperature, immersion time, and salt purity. Contamination in the salt bath—something I’ve seen happen from improper handling—can lead to inconsistent strengthening and even surface defects.

After strengthening, the glass becomes more challenging to cut or shape. While you can still use laser cutting or diamond scribing, these processes must be carefully controlled to avoid compromising the compressive stress layer. Any subsequent thermal processing must stay below the glass’s strain point to avoid relaxing those carefully introduced stresses.

The screen printing process itself must be adapted. Squeegee pressure, ink viscosity, and mesh selection all need optimization for strengthened glass. Too much pressure might not break the glass, but it can affect the registration of fine features, especially near the edges of the glass where the stress profile changes.

6 Future Directions and Innovations

The field isn’t standing still. Researchers are developing thinner yet stronger glass compositions that can undergo deeper compression layers. I’m particularly excited about some of the new alkali-free compositions that allow for even higher surface compression values.

There’s also growing interest in combining chemical strengthening with other functional treatments. For instance, applying oleophobic coatings that resist fingerprints directly over the strengthened surface, or integrating anti-glare treatments that don’t compromise the strength. The challenge is always ensuring these additional processes don’t interfere with the ion exchange or the screen printing.

Perhaps the most promising development is in the area of sustainability. Companies are working on closed-loop systems for the potassium nitrate baths, recovering and purifying the salt for repeated use. This not only reduces environmental impact but also lowers production costs—a win-win for manufacturers and the planet.

As devices continue to evolve—becoming foldable, rollable, or taking entirely new forms—the demand for stronger, more durable cover glass will only increase. The combination of chemical strengthening and precision screen printing will remain at the forefront of enabling these next-generation technologies.