Anti-UV Ink in Screen Printing for Cover Glass

Our anti-UV screen printing inks are built for endurance. Designed specifically for cover glass, they shield your product’s graphics from the sun’s harsh, fading rays. We use advanced stabilizers to ensure colors stay vibrant and sharp, even under prolonged outdoor exposure. The result is a superior, lasting finish that resists yellowing and wear. Perfect for automotive displays, outdoor kiosks, and consumer electronics. It’s the essential protection you need to maintain a flawless look and professional branding for the long haul.

Enhancing Durability: The Role of Anti-UV Ink in Screen Printing for Cover Glass

Introduction

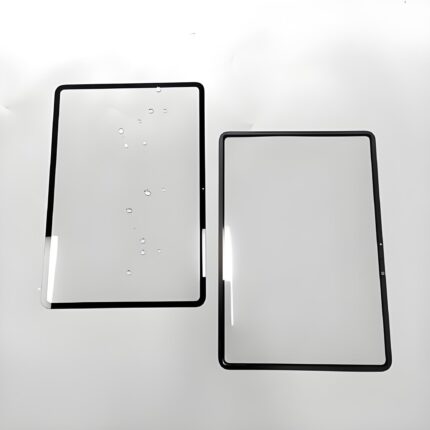

In today’s world, where electronic devices are ubiquitous, the demand for durable and visually appealing cover glass has skyrocketed. From smartphones and tablets to automotive displays and industrial control panels, cover glass protects sensitive screens while providing a sleek interface. One critical aspect of enhancing both the aesthetics and longevity of these glass surfaces is screen printing with anti-UV inks. This technology not only adds branding and decorative elements but also significantly improves the product’s resistance to environmental stressors, particularly ultraviolet (UV) light.

Screen printing, a technique that has been refined over decades, involves transferring ink onto a substrate through a mesh screen. When applied to cover glass, this process must meet high standards of precision and durability. The incorporation of anti-UV properties into these inks addresses a common yet often overlooked problem: the degrading effects of prolonged UV exposure. Without such protection, printed designs can fade, discolor, or peel, compromising the device’s appearance and functionality. This article delves into the specifics of anti-UV ink screen printing for cover glass, exploring its composition, application process, benefits, and future trends.

What is Anti-UV Ink?

Anti-UV ink is a specialized type of ink formulated to resist the harmful effects of ultraviolet radiation. Unlike standard inks, which may contain pigments and binders that break down under UV light, anti-UV inks include additives that absorb or reflect UV rays, preventing them from penetrating the printed layer. These inks are typically composed of four main elements: pigments for color, resins for adhesion and gloss, solvents for viscosity control, and UV stabilizers such as hindered amine light stabilizers (HALS) or UV absorbers like benzotriazoles.

The science behind these inks revolves around their ability to mitigate photodegradation. When UV light hits a printed surface, it can cause chemical bonds in the ink to break, leading to fading or chalking. UV stabilizers work by either absorbing the UV energy and converting it into harmless heat or by scavenging free radicals generated during the degradation process. This ensures that the ink maintains its color intensity and structural integrity over time, even when exposed to direct sunlight or other UV sources.

For cover glass applications, these inks are engineered to adhere firmly to glass surfaces, which are inherently non-porous and smooth. This requires careful selection of resins and additives to ensure excellent adhesion, flexibility, and resistance to abrasion. Additionally, anti-UV inks must be compatible with the high-temperature processes often used in glass manufacturing, such as tempering or annealing, without losing their protective properties.

The Screen Printing Process for Cover Glass

Screen printing on cover glass is a meticulous process that demands precision and expertise. It begins with the preparation of the glass substrate. The cover glass is thoroughly cleaned to remove any contaminants, such as dust, oils, or residues, that could impair ink adhesion. This step is crucial, as even minor impurities can lead to defects in the final print.

Next, the design is transferred to a screen, which is typically made of polyester or stainless steel mesh stretched over a frame. The mesh count (number of threads per inch) is chosen based on the detail of the design and the viscosity of the ink; finer meshes are used for detailed graphics, while coarser meshes are suitable for bold, solid areas. A stencil of the design is created on the screen using a photosensitive emulsion. When exposed to UV light through a film positive, the emulsion hardens except in the areas where the design allows light to pass, leaving open mesh patterns for ink transfer.

During printing, the screen is positioned over the glass, and ink is applied to the top of the screen. A squeegee is then used to push the ink across the screen, forcing it through the open mesh onto the glass surface. The viscosity of anti-UV ink must be carefully controlled to ensure even coverage without smudging or bleeding. After printing, the ink is cured to solidify the print and develop its protective properties. Curing methods vary; some inks are air-dried, but UV-curable inks are increasingly popular due to their rapid curing times and enhanced durability. These inks polymerize almost instantly when exposed to UV light, forming a tough, cross-linked film that is highly resistant to wear and environmental factors.

Benefits of Using Anti-UV Ink in Cover Glass Applications

The primary advantage of anti-UV ink is its ability to preserve the visual quality of printed designs over time. Products featuring such prints, like outdoor kiosks or automotive displays, are consistently exposed to sunlight. Without UV protection, the inks would degrade, causing logos to fade and instructions to become illegible. Anti-UV inks maintain color vibrancy and readability, ensuring that the product remains aesthetically pleasing throughout its lifespan.

Durability is another key benefit. Anti-UV inks are formulated to withstand not only UV radiation but also other environmental challenges, such as moisture, temperature fluctuations, and chemical exposure. This makes them ideal for applications in harsh environments, including industrial settings or outdoor installations. The enhanced adhesion to glass prevents peeling or cracking, which is essential for maintaining the integrity of the display and protecting underlying components.

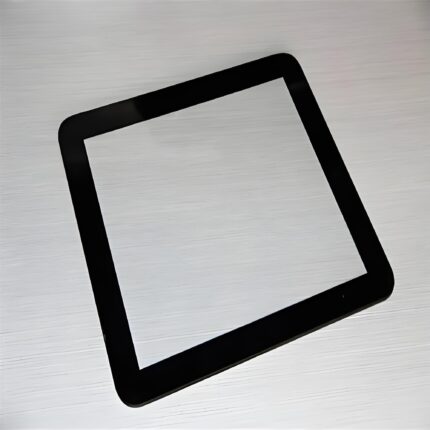

From a functional perspective, screen printing with anti-UV ink can also add value by enabling the creation of border designs that reduce light leakage in displays or hide internal components. This improves the overall user experience by providing a cleaner, more seamless look. Additionally, the use of UV-curable versions of these inks supports faster production cycles, as curing takes only seconds compared to minutes or hours for traditional inks. This efficiency boost can lead to cost savings and higher throughput in manufacturing.

Challenges and Considerations

Despite its benefits, screen printing with anti-UV ink on cover glass presents several challenges. One significant issue is ink adhesion. Glass is a difficult substrate due to its smooth, non-porous nature. To address this, manufacturers often treat the glass surface with primers or coatings that improve ink bonding. Alternatively, inks with specially formulated resins can enhance adhesion without additional steps.

Color matching and consistency can also be problematic. Anti-UV additives may slightly alter the ink’s color, requiring adjustments during formulation. Batch-to-batch consistency is critical for large production runs, so rigorous quality control measures are necessary to ensure that each batch meets color and performance standards.

Environmental and health considerations are increasingly important. Some traditional anti-UV inks contain volatile organic compounds (VOCs) that can be harmful during printing and curing. The industry is shifting towards water-based or UV-curable inks, which have lower VOC emissions and are safer for workers. However, these alternatives may require changes in equipment or processes, such as installing UV curing lamps or adjusting drying times.

Cost is another factor. Anti-UV inks are generally more expensive than standard inks due to their specialized additives. However, this higher initial cost is often offset by the longer lifespan of the product and reduced need for maintenance or replacements.

Future Trends and Innovations

The future of anti-UV ink in screen printing for cover glass is shaped by advancements in materials and technology. Nanotechnology is playing a growing role; nanoparticles can be incorporated into inks to enhance UV absorption without affecting color or transparency. These nano-enhanced inks offer superior protection while allowing for thinner print layers, which is advantageous for sleek, modern device designs.

Sustainability is a major driver of innovation. Researchers are developing bio-based UV stabilizers derived from natural sources, reducing reliance on synthetic chemicals. Additionally, the adoption of recycling-compatible inks is gaining traction, allowing printed glass to be recycled without harmful residues—a key consideration in the circular economy.

Digital integration is another trend. While screen printing remains dominant for large runs, digital printing technologies are emerging for shorter runs or highly customized designs. These methods can use anti-UV inks in a more precise, waste-minimizing manner, complementing traditional screen printing.

Finally, as devices become smarter, there is growing interest in functional prints beyond decoration. Anti-UV inks could be combined with conductive elements for integrated touch sensors or anti-glare properties, adding value while maintaining durability.

Conclusion

Anti-UV ink screen printing is a vital process in the manufacture of cover glass for modern electronic devices. It combines aesthetic appeal with robust protection against environmental damage, ensuring that products remain functional and visually attractive over time. While challenges such as adhesion and cost exist, ongoing innovations in ink formulation and printing technology are continuously addressing these issues. As demand for durable, high-quality cover glass grows, the role of anti-UV inks will only become more critical, driving further advancements in this essential field.