AGC (Asahi Glass) Electronic Display Glass: Premium Performance for Modern Screens

AGC Display Glass: The Smart Choice for Premium Screens

Upgrade your devices with AGC’s high-performance glass solutions. Our chemically strengthened glass offers unmatched durability (7H-9H hardness) and crystal-clear visuals (>92% light transmission). Choose from anti-glare, anti-reflective, or smudge-proof coatings to enhance user experience.

Perfect for:

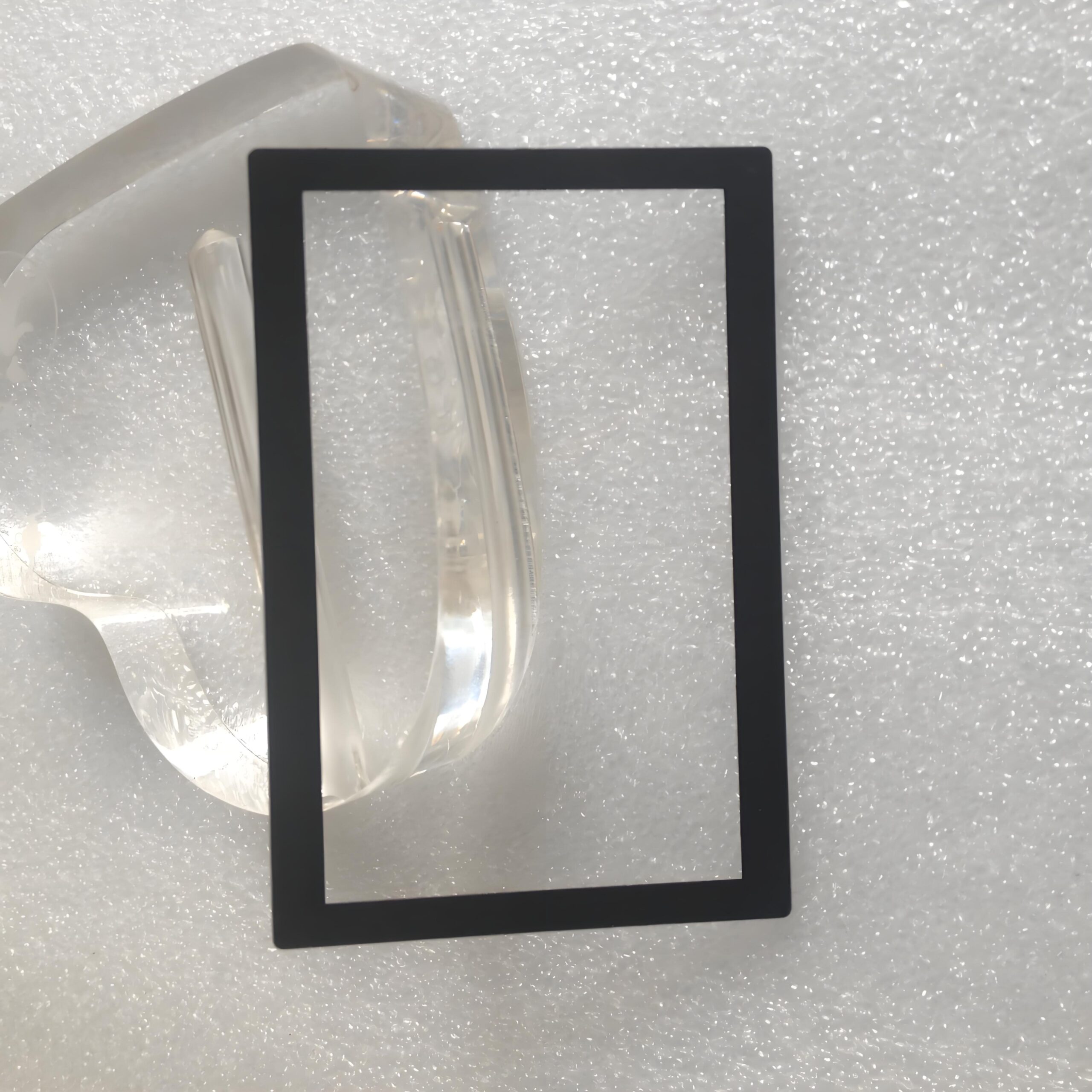

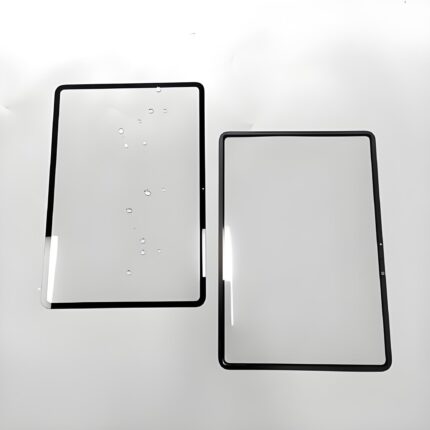

• Smartphones & tablets

• Car dash displays

• Medical equipment screens

• Industrial control panels

Customize with various printing options including ceramic and conductive inks. Backed by 40+ years of glass innovation, we deliver reliable solutions tailored to your needs.

Get in touch for samples and see the difference quality glass makes!

Introduction to AGC Electronic Display Glass Technology

AGC (Asahi Glass Company), a global leader in specialty glass manufacturing, produces high-performance display glass solutions for cutting-edge electronic devices. With over a century of glass innovation, AGC’s display glass combines exceptional durability, optical clarity, and advanced surface treatments to meet the demanding requirements of today’s touchscreen applications.

Key Advantages Over Conventional Glass

| Property | AGC Display Glass | Standard Soda-Lime Glass |

|---|---|---|

| Surface Hardness | 7H-9H pencil hardness | 4H-5H pencil hardness |

| Impact Resistance | 3-5x stronger | Prone to cracking |

| Thickness Tolerance | ±0.05mm | ±0.15mm |

| Light Transmission | >92% | 89-91% |

| Chemical Durability | Resists acids/alkalis | Vulnerable to corrosion |

Advanced Surface Treatment Options

1. Anti-Reflective (AR) Coating

-

Reflectance: <1.2% at 550nm wavelength

-

Haze: <0.3%

-

Durability: Withstands 10,000+ cleaning cycles

2. Anti-Glare (AG) Treatment

-

Glare Reduction: 70-85%

-

Surface Roughness: 0.08-0.25μm (adjustable)

-

Diffusion Control: 5°-20° light scattering

3. Anti-Fingerprint (AF) Coating

-

Contact Angle: >110° (water), >105° (oil)

-

Coefficient of Friction: 0.08-0.15

-

Abrasion Resistance: 7,500+ Taber cycles

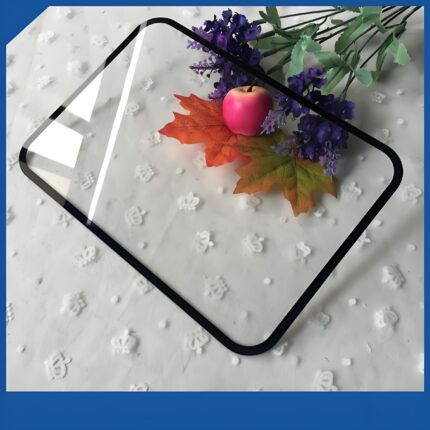

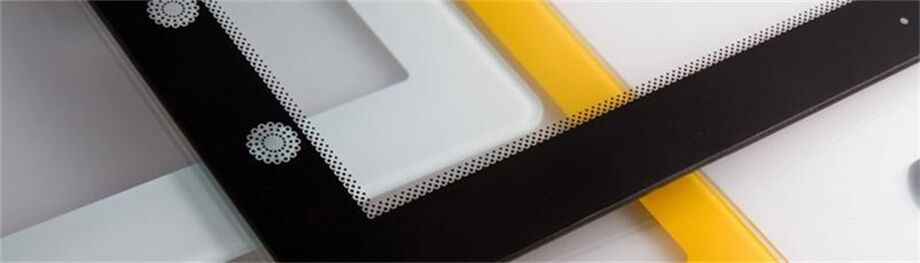

Screen Printing Ink Options

AGC glass supports various printing techniques for optimal customization:

| Ink Type | Features | Best For |

|---|---|---|

| Ceramic Ink | High opacity, UV resistant | Perimeter borders, logos |

| Transparent Ink | 85-95% light transmission | Decorative elements |

| Conductive Ink | Resistivity 10-100Ω/sq | EMI shielding, sensors |

| Elastic Ink | 200-300% stretchability | Flexible displays |

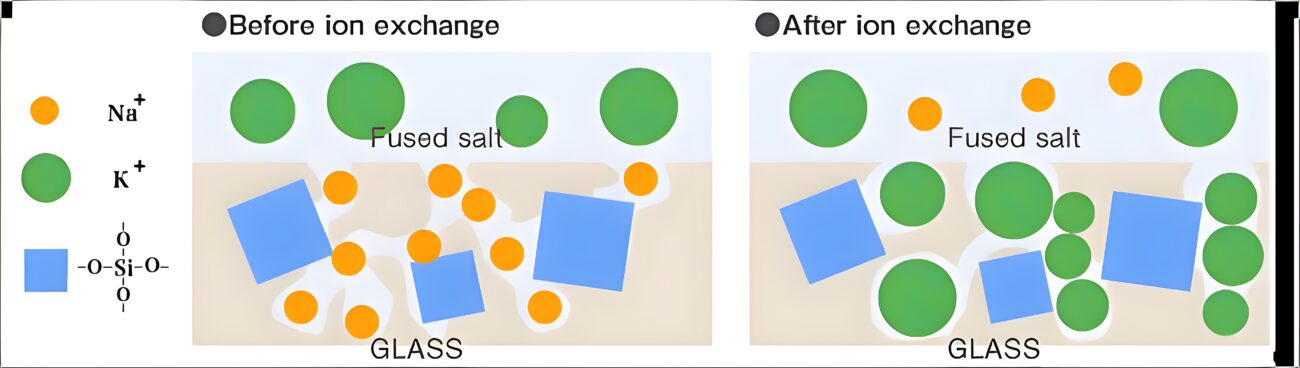

Chemical Strengthening Process

AGC’s proprietary ion-exchange technology delivers:

-

Surface Compression: 600-900MPa

-

Case Depth: 30-50μm

-

Flexural Strength: 2-3x improvement

-

Temperature Resistance: Up to 300°C

The process involves:

-

Pre-cleaning (ultrasonic + plasma)

-

Molten Salt Bath (400°C potassium nitrate)

-

Quenching for stress equilibrium

-

Post-treatment inspection

Application Scenarios

Consumer Electronics

-

Foldable Phones: Ultra-thin 0.3mm versions available

-

Tablets: Damage-resistant for education sector

-

Laptops: 15-17″ cover glass solutions

Automotive Displays

-

Center Stack: 10-15″ curved glass options

-

Instrument Clusters: Anti-glare variants

-

HUD Systems: High-transmission AR versions

Industrial & Medical

-

Factory HMIs: Chemical-resistant formulations

-

Medical Monitors: Antimicrobial coatings available

-

POS Systems: Scratch-proof for retail environments

Quality Assurance Standards

All AGC display glass undergoes:

-

Optical Inspection: Automated defect detection

-

Mechanical Testing: 4-point bend, drop tests

-

Environmental Testing: 85°C/85% RH, thermal shock

-

Chemical Resistance: ISO 9211-4 compliance

Why Choose AGC Display Glass?

-

Proven Reliability: 40+ years in display glass manufacturing

-

Custom Solutions: Tailored thickness, coatings, and printing

-

Global Support: Technical assistance worldwide

-

Sustainable Production: Eco-friendly manufacturing processes

Request samples or technical documentation: Our engineering team can help specify the ideal glass solution for your display requirements, whether you need ultra-thin flexible glass for foldables or ruggedized versions for industrial applications.