Advanced Electronic Cover Glass Technologies for OLED and LCD Panels

Advanced Electronic Cover Glass Technologies for OLED and LCD Panels

Today’s high-performance displays require cover glass solutions engineered for specific panel technologies. For OLED applications, ultra-thin (<0.5mm) chemically strengthened glass with exceptional flexibility prevents image distortion while protecting delicate organic materials. LCD panels benefit from specialized cover glass featuring:

-

92%+ light transmission to maintain brightness

-

Low birefringence for accurate color reproduction

-

Thermal stability to withstand backlight heat

Advanced solutions now incorporate:

• Integrated polarizers for improved contrast

• UV-filtering layers to prevent OLED degradation

• Anti-glare treatments optimized for different lighting conditions

Manufacturers are pushing boundaries with hybrid glass-polymer composites that offer:

✓ 50% better impact resistance than standard glass

✓ Compatibility with in-cell touch technology

✓ Reduced weight for portable devices

Advanced Electronic Cover Glass: Next-Generation Protection for High-Tech Displays

The Critical Role of Cover Glass in Modern Display Technology

Today’s premium electronic devices demand cover glass that does more than just protect – it enhances performance. Advanced electronic cover glass serves as the crucial interface between users and their devices, combining:

-

Military-grade protection against drops and scratches

-

Optical clarity rivaling bare displays

-

Advanced functionality like anti-microbial properties

From smartphones to automotive displays, the right cover glass solution can mean the difference between a good device and a great one.

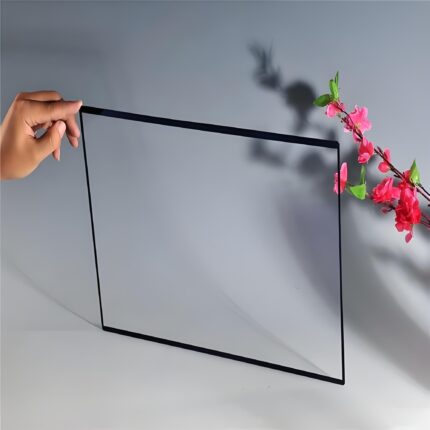

Material Innovations Driving the Industry

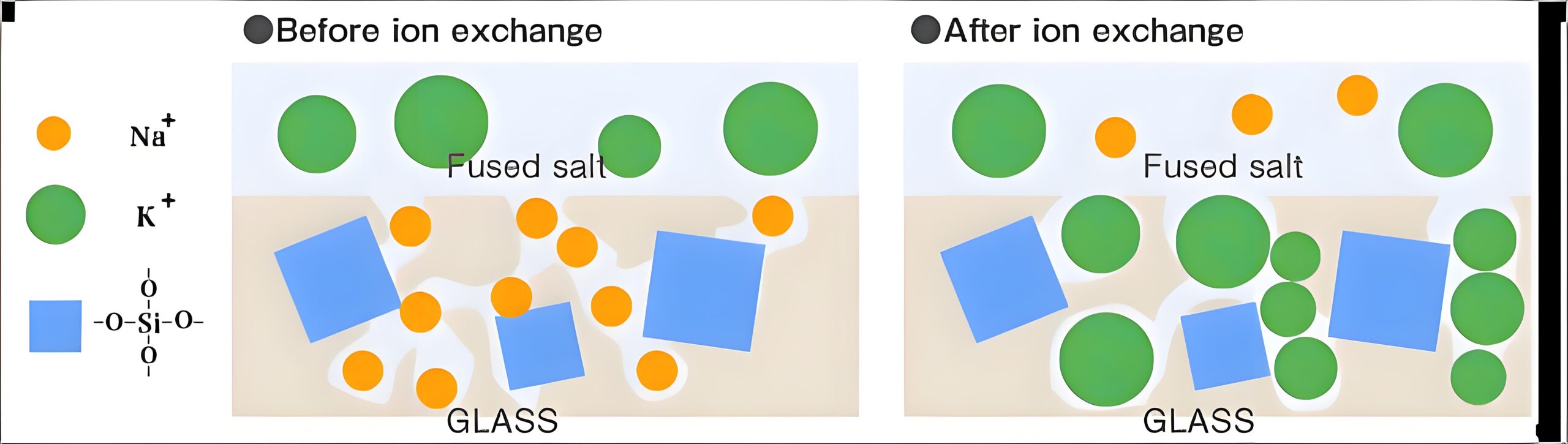

Chemically Strengthened Aluminosilicate Glass

The industry standard for high-end devices offers:

-

800+ MPa surface compression

-

0.3-1.1mm thickness options

-

92-95% light transmission

Hybrid Glass-Polymer Composites

Emerging solutions provide:

-

Enhanced flexibility for foldables

-

Superior impact absorption

-

Lighter weight (up to 30% reduction)

Specialty Formulations

Niche applications benefit from:

-

UV-blocking compositions for outdoor displays

-

Conductive-doped glass for integrated antennas

-

High-temperature variants for automotive use

Technical Specifications That Matter

Optical Performance

-

<0.5% haze for crystal-clear images

-

<1.5% reflectivity with AR coatings

-

Color neutrality (ΔE < 1.0)

Durability Benchmarks

-

6H-9H pencil hardness

-

1-3m drop survival depending on thickness

-

200,000+ bend cycles for flexible versions

Environmental Resistance

-

-40°C to 105°C operational range

-

UV stability (5000+ hours testing)

-

Chemical resistance to oils and cleaners

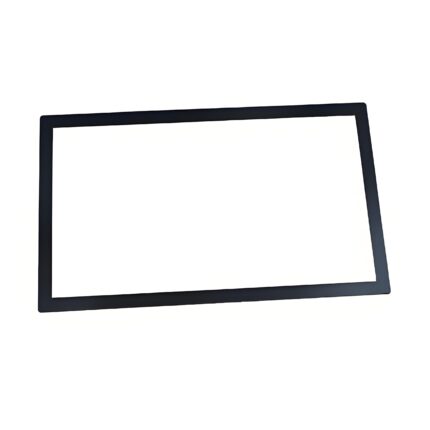

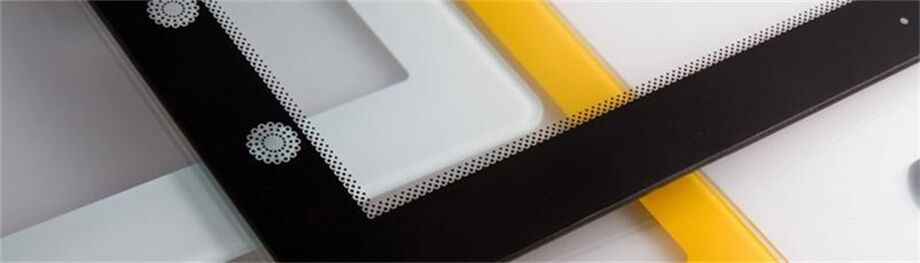

Application-Specific Solutions

Smartphone and Tablet Displays

-

0.5mm ultra-thin options

-

Edge-to-edge coverage

-

Under-display camera compatibility

Automotive Displays

-

Vibration-resistant formulations

-

Anti-glare and anti-fingerprint

-

Heated glass options

Industrial and Medical Equipment

-

Anti-microbial surfaces

-

Enhanced chemical resistance

-

EMI shielding capabilities

Selection Guide for Design Engineers

Key Considerations

-

Environmental factors (temperature, humidity, UV)

-

Optical requirements (transmission, clarity)

-

Durability needs (impact, scratch resistance)

-

Special features (conductivity, flexibility)

Specification Checklist

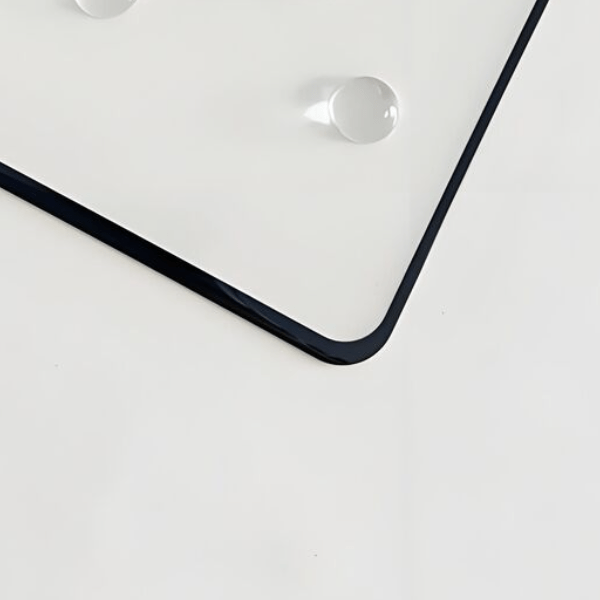

-

Thickness tolerance (±0.03mm)

-

Surface compression (minimum 700MPa)

-

Coating specifications (AR, AF, etc.)

-

Edge treatment requirements

The Future of Cover Glass Technology

Emerging Innovations

-

Self-healing surfaces for scratch repair

-

Dynamic privacy filters

-

Energy-harvesting glass

Market Trends

-

Growing demand for foldable displays

-

Increased automotive display real estate

-

Medical device applications