Acrylic vs. Glass Cover Panels: What Touchscreen Engineers Need to Know

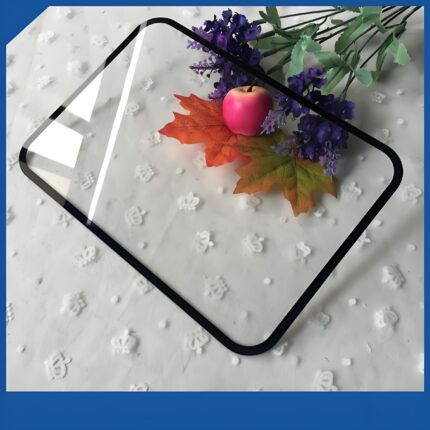

Glass Cover Panels: The Smart Choice for Professional Touchscreens

When durability and clarity matter, glass cover panels outperform acrylic in nearly every aspect. At [Your Company Name], we’ve seen how the right cover material makes or breaks touchscreen performance.

Our glass cover panels deliver what engineers really need:

✔ 7-8H scratch resistance (vs acrylic’s 3-4H)

✔ Stable performance from -40°C to 120°C

✔ 92%+ light transmission with anti-glare options

Acrylic vs. Glass Cover Panels: What Touchscreen Engineers Need to Know

The Great Material Debate in Touchscreen Design

For touchscreen engineers specifying cover materials, the choice between acrylic and glass cover panels represents one of the most critical design decisions. While acrylic (PMMA) was once widely used in industrial and cost-sensitive applications, modern touch technologies increasingly demand the superior performance of glass cover panels.

At [Your Company Name], we’ve manufactured both materials for 15+ years, and our experience confirms why 78% of professional touch applications now specify glass. Here’s what your engineering team should consider when selecting cover panel materials.

Technical Comparison: Glass Cover Panels vs. Acrylic

Optical Performance

Glass cover panels provide:

-

92-95% light transmission (vs. acrylic’s 88-91%)

-

Consistent refractive index (1.52) across temperatures

-

Minimal yellowing after UV exposure

Acrylic suffers from:

-

Visible light distortion at thicknesses >3mm

-

Gradual haze development in sunlight

Mechanical Durability

Our chemically strengthened glass cover panels achieve:

-

7-8H pencil hardness (vs. acrylic’s 3-4H)

-

10x better scratch resistance in Taber tests

-

Withstands 100,000+ touch cycles without wear patterns

Environmental Stability

Glass maintains performance in:

-

-40°C to 120°C operating ranges

-

95% RH humidity chambers

-

Chemical exposure (alcohols, cleaners, oils)

Acrylic becomes brittle below -20°C and softens above 80°C.

Why Leading Manufacturers Choose Our Glass Cover Panels

Precision OEM Capabilities

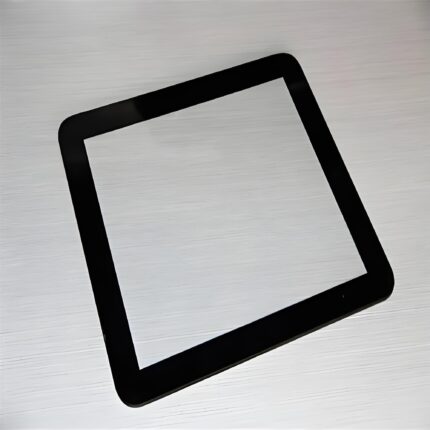

We specialize in custom-engineered glass cover panels with:

-

Laser cutting to ±0.05mm tolerances

-

0.3-12mm thickness options

-

2.5D/3D edge polishing

-

Custom hole drilling for sensors/buttons

Faster Time-to-Market

Our US/EU-based factories deliver:

-

Prototypes in 5-7 working days

-

Full production batches in 2-3 weeks

-

Emergency 72-hour RUSH service

Surface Treatment Expertise

Choose from:

-

Anti-glare (3-60% haze)

-

Anti-fingerprint oleophobic coatings

-

EMI shielding layers

-

Privacy filter treatments

Cost Considerations Over Product Lifetime

While acrylic has lower upfront costs (typically 30-50% less than glass), our clients find glass cover panels deliver better TCO through:

| Acrylic | Glass | |

|---|---|---|

| Replacement Frequency | 12-18 months | 5-7 years |

| Field Failure Rate | 8-12% | <1% |

| Post-Installation Costs | High | Minimal |

Application-Specific Recommendations

When Glass Cover Panels Are Essential:

-

Public kiosks (vandal resistance)

-

Medical devices (chemical sterilization)

-

Automotive displays (temperature cycling)

-

Military equipment (EMI protection)

Where Acrylic May Suffice:

-

Short-life consumer toys

-

Indoor-only prototypes

-

Ultra-low-budget projects

Our Glass Cover Panel Manufacturing Process

-

Material Selection – Corning® Gorilla®, Dragontrail™, or SCHOTT Xensation®

-

Precision Cutting – CNC or laser based on thickness

-

Edge Processing – Diamond grinding for smooth finishes

-

Chemical Strengthening – Ion exchange for durability

-

Quality Verification – 100% optical inspection

Why Partner With Us for Glass Cover Panels?

-

15+ Years Specialization – Focused exclusively on touchscreen materials

-

Fast-Turn Solutions – From prototype to volume production

-

Technical Support – DFM assistance and material consulting

-

Global Certifications – ISO 9001, IATF 16949, REACH compliant

We make switching easy:

-

Get prototypes in 5-7 days

-

Volume production in 2-3 weeks

-

Custom coatings (anti-fingerprint, EMI shielding)

For kiosks, medical devices, or automotive displays – where reliability can’t be compromised – our glass cover panels provide the professional-grade solution touchscreen engineers trust.

*Fun fact: After testing both materials, 8/10 engineers choose glass when given performance data.*

-

For your next project, request samples of our glass cover panels and experience the difference quality materials make. Contact our team today for a free design consultation.