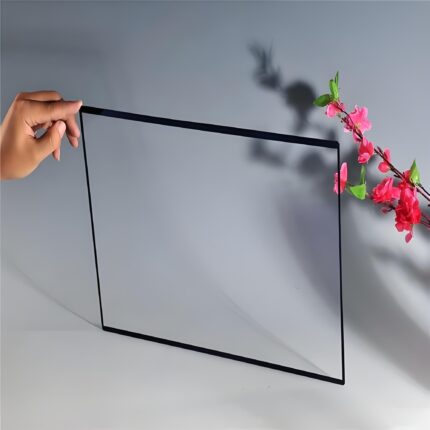

2mm Gorilla Glass: The Ultimate High-Performance Display Solution

2mm Gorilla Glass – Superior Strength & Clarity for Demanding Applications

Thinner yet tougher than standard glass, 2mm Gorilla Glass delivers exceptional scratch resistance (6H-8H hardness) and 2-3x better impact protection. With >92% light transmission and optional AR (anti-reflective), AG (anti-glare), and AF (anti-fingerprint) coatings, it enhances visibility and durability for smartphones, automotive displays, medical equipment, and industrial touchscreens. Compared to traditional glass, it’s 5% lighter, more shatter-resistant, and customizable for glare reduction or smudge-proof surfaces. Ideal for high-performance displays where durability and optical clarity matter.

Upgrade your project with Gorilla Glass—contact us for samples!

In an era where durability and optical clarity are non-negotiable, 2mm Gorilla Glass emerges as the superior choice for industries ranging from consumer electronics to automotive and industrial applications. Unlike traditional glass, Gorilla Glass undergoes a specialized chemical strengthening process, making it thinner, lighter, and significantly more resistant to scratches and impacts.

This guide explores its key advantages, technical comparisons with standard glass, available coatings (AR, AG, AF), and real-world applications—helping you determine if it’s the right fit for your project.

Gorilla Glass vs. Standard Glass: Key Differences

When comparing 2mm Gorilla Glass to conventional 2mm soda-lime glass, the differences in performance are striking:

| Property | 2mm Gorilla Glass | Standard 2mm Glass |

|---|---|---|

| Scratch Resistance | 6H-8H (harder than metal) | 4H-5H (easily scratched) |

| Impact Resistance | 2-3x stronger | Prone to cracking |

| Surface Hardness | ~700 Vickers | ~500 Vickers |

| Optical Clarity | >92% light transmission | ~90% light transmission |

| Weight | 5% lighter | Standard weight |

| Durability | Chemically strengthened | Annealed (weaker) |

Why These Differences Matter

-

Fewer cracks & breaks → Longer lifespan for devices.

-

Better touch sensitivity → Smoother user experience.

-

Higher clarity → More vibrant displays.

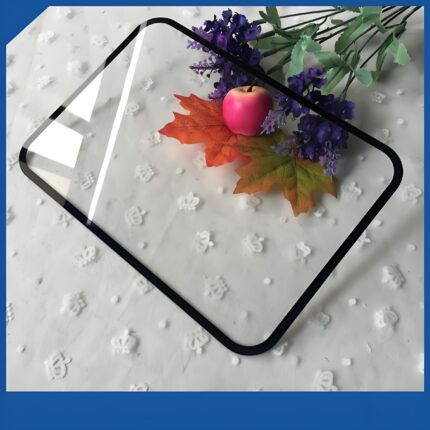

Advanced Coatings: AR, AG, and AF

To further enhance performance, Gorilla Glass can be treated with specialized coatings:

1. Anti-Reflective (AR) Coating

-

Reflectance: <1% (vs. 8% on bare glass).

-

Light Transmission: Up to 99% (minimal glare).

-

Best For: High-end displays, outdoor kiosks, VR lenses.

2. Anti-Glare (AG) Treatment

-

Haze Level: 10%-60% (customizable diffusion).

-

Glare Reduction: 70%+ compared to untreated glass.

-

Best For: Industrial control panels, medical monitors, automotive dashboards.

3. Anti-Fingerprint (AF) Coating

-

Contact Angle: >110° (strong oil repellency).

-

Smudge Resistance: 80%+ reduction in visible fingerprints.

-

Best For: Smartphones, tablets, touchscreen devices.

Combination Option: AR + AF coatings are popular for smartphones, while AG + AF is ideal for industrial touchscreens.

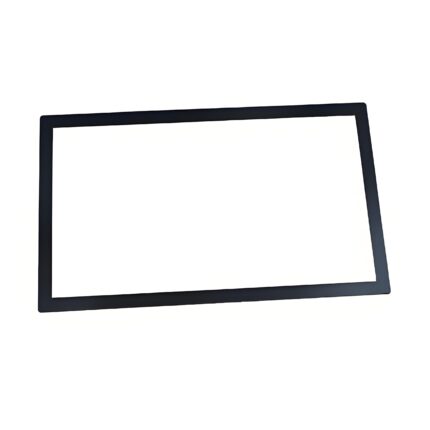

Top Applications of 2mm Gorilla Glass

1. Consumer Electronics

-

Smartphones & Tablets – Scratch-resistant screens with AF coating.

-

Laptops & Wearables – Lightweight yet durable cover glass.

2. Automotive & Aviation

-

Digital Dashboards – Resists vibrations and extreme temperatures.

-

Aircraft Displays – AG coating minimizes cockpit glare.

3. Industrial & Medical Devices

-

Factory Control Panels – Withstands harsh environments.

-

Surgical Monitors – Hygienic AF coating for easy cleaning.

4. Retail & Public Displays

-

Interactive Kiosks – AR coating improves sunlight readability.

-

Digital Signage – Vandal-resistant for high-traffic areas.

Conclusion: Is 2mm Gorilla Glass Right for You?

If your project demands a thinner, stronger, and more optically advanced glass, 2mm Gorilla Glass is the clear winner. With optional AR, AG, and AF coatings, it outperforms traditional glass in durability, clarity, and usability—making it ideal for high-end electronics, automotive, medical, and industrial applications.

Need a custom solution? Contact us today for samples and technical support!