Blog

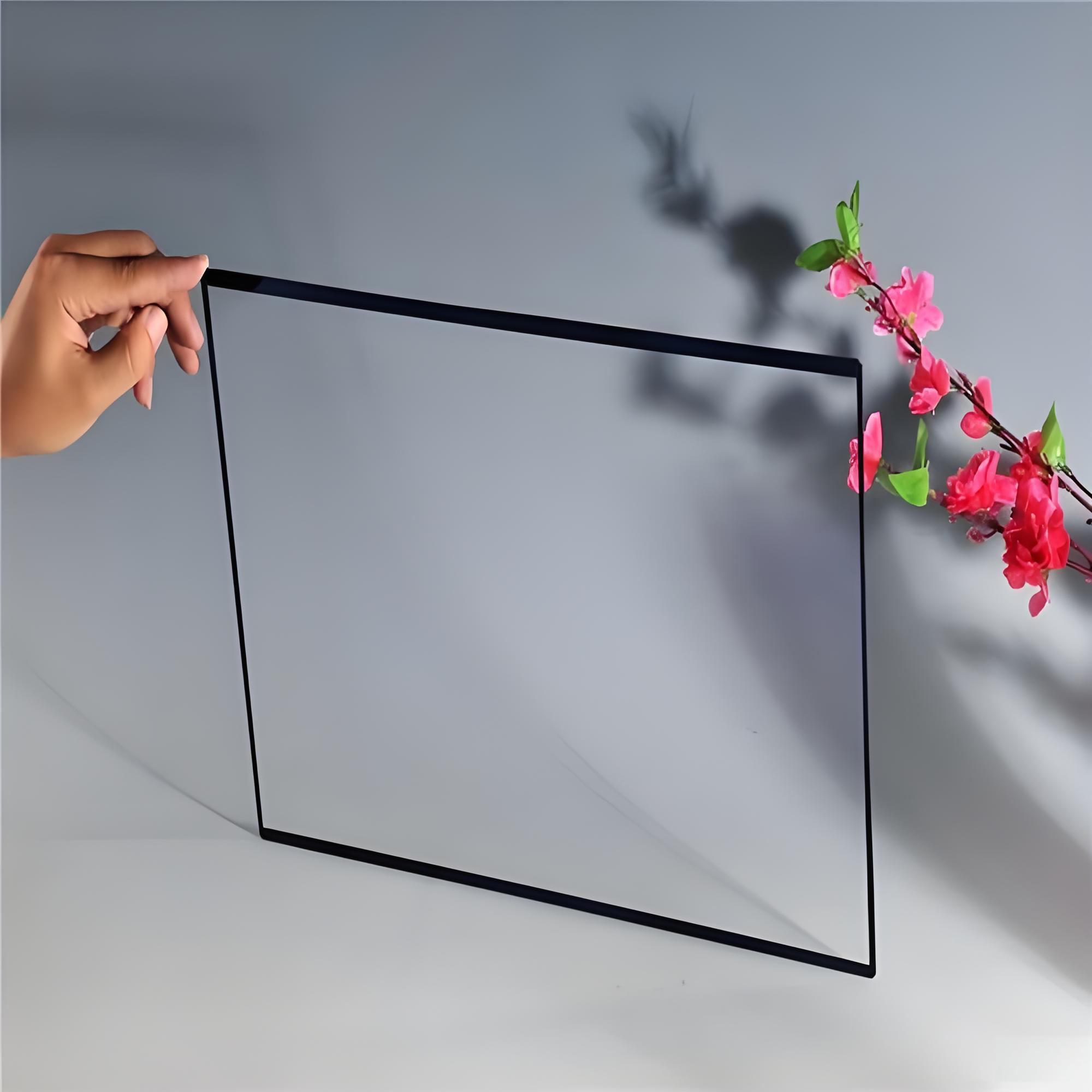

AF Glass and Its Role in Reducing Fingerprint Marks

In the digital age, the demand for pristine, smudge-free glass surfaces continues to rise. Whether it’s the display of a premium smartphone, the lens of a high-end camera, or the cover of a smart wearable device, maintaining clarity and cleanliness is paramount. DONGGUAN WEIMAN TECHNOLOGY CO.,LTD (abbreviated as WEIMAN TECHNOLOGY) stands at the forefront of this innovation with advanced AF (Anti-Fingerprint) glass solutions. This article explores the significance of AF glass, its impact on reducing fingerprint marks, and the broader implications for industries such as glass lens factories and display glass factories.

What Is AF Glass?

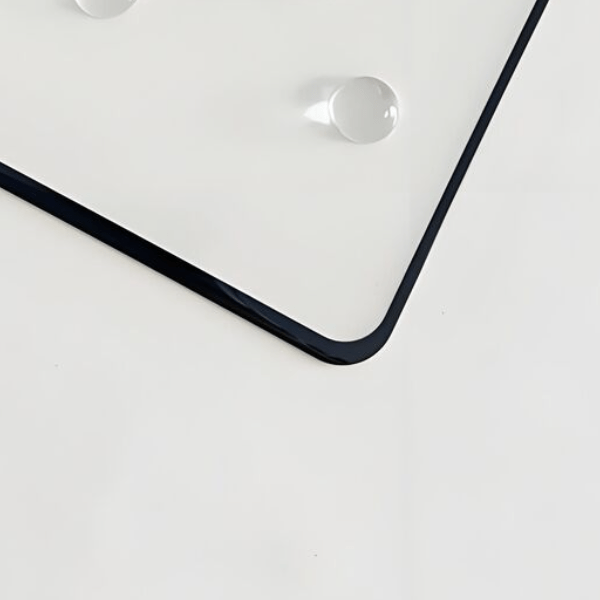

AF glass, short for Anti-Fingerprint glass, is a type of glass that features a special surface coating designed to minimize the appearance and adhesion of fingerprint marks. The coating, often based on oleophobic or hydrophobic materials, repels oils from human skin, making it easier to wipe away smudges and maintain a clear, clean surface.

For companies like WEIMAN TECHNOLOGY, the development and refinement of AF glass are essential in meeting the evolving needs of consumers who expect not only visual clarity but also effortless maintenance from their electronic devices.

How Does AF Glass Work?

The secret behind AF glass lies in its surface chemistry. The oleophobic coating creates a low-surface-energy layer that resists oil and water. When a finger touches the glass, oils are less likely to adhere, resulting in fewer visible fingerprints. Additionally, any marks that do appear can be wiped away with minimal effort, maintaining the glass’s pristine look.

This technology is now a standard requirement for many products manufactured by leading glass lens factories and display glass factories. These facilities, including those partnered with WEIMAN TECHNOLOGY, integrate AF coatings into their production lines to deliver superior end-user experiences.

Advantages of AF Glass in Everyday Devices

- Enhanced Visual Clarity: AF glass ensures that screens and lenses remain clear, free from distracting smudges and fingerprints, which is critical for devices like smartphones, tablets, and cameras.

- Ease of Cleaning: The oleophobic layer allows users to clean their devices quickly and efficiently, reducing the need for harsh cleaning agents or frequent wiping.

- Improved Durability: AF coatings often add an extra layer of protection to the glass surface, making it more resistant to scratches and minor abrasions.

- Better User Experience: Clean screens and lenses translate to better touch sensitivity, accurate image capture, and a more premium feel overall.

These benefits are not just limited to consumer electronics. AF glass is also widely used in automotive displays, medical equipment, and industrial control panels, where cleanliness and visibility are critical.

WEIMAN TECHNOLOGY: Pioneering AF Glass Solutions

As a leading innovator in the glass processing industry, WEIMAN TECHNOLOGY has invested heavily in research and development to perfect AF glass coatings. The company’s state-of-the-art facilities employ advanced deposition techniques to ensure uniform, durable, and highly effective anti-fingerprint layers on every glass product.

WEIMAN TECHNOLOGY collaborates closely with glass lens factories to supply high-performance AF glass for camera modules, optical devices, and precision instruments. At the same time, its partnerships with display glass factories enable the mass production of fingerprint-resistant screens for smartphones, tablets, and automotive displays.

Quality Control and Industry Standards

To maintain its reputation for excellence, WEIMAN TECHNOLOGY adheres to stringent quality control protocols. Each batch of AF glass undergoes rigorous testing for adhesion, durability, and optical clarity. The company also stays up-to-date with international standards, ensuring compatibility with the latest manufacturing processes used by glass lens and display glass factories worldwide.

Industry Trends: The Growing Importance of AF Glass

The global shift towards touch-based interfaces and high-resolution displays has put pressure on manufacturers to deliver glass surfaces that remain clean and responsive. As a result, demand for AF glass is surging across multiple sectors.

- Consumer Electronics: Modern smartphones and tablets almost universally feature AF glass, enhancing user satisfaction and device longevity.

- Automotive: Touchscreen dashboards and infotainment systems benefit from AF coatings that reduce glare and smudges, improving safety and aesthetics.

- Wearable Devices: Smartwatches and fitness trackers require durable, easy-to-clean surfaces due to frequent handling and exposure to sweat and oils.

- Optical Instruments: Camera lenses and medical imaging devices rely on AF glass to maintain clarity and accuracy in demanding environments.

Glass lens factories and display glass factories are rapidly scaling up their capabilities to meet this demand, often turning to trusted partners like WEIMAN TECHNOLOGY for advanced materials and coatings.

Challenges and Future Directions

While AF glass technology has made significant strides, challenges remain. Ensuring long-term durability of the coating, maintaining optical clarity, and developing eco-friendly manufacturing processes are ongoing areas of research. WEIMAN TECHNOLOGY is actively exploring new materials and deposition techniques to address these challenges, keeping the company at the cutting edge of the industry.

Additionally, as sustainability becomes a core concern, glass manufacturers are seeking ways to reduce waste and energy consumption during production. AF glass, with its low-maintenance properties, can contribute to longer product lifespans and reduced cleaning needs, aligning with broader environmental goals.

Conclusion: The Future of Clean, Clear Glass

AF glass has transformed the way we interact with everyday technology, offering a solution to the persistent problem of fingerprint marks and smudges. Companies like WEIMAN TECHNOLOGY are driving this evolution by supplying high-quality AF glass to glass lens factories and display glass factories worldwide. As the industry continues to innovate, users can look forward to even cleaner, more durable, and more sustainable glass surfaces in the years ahead.

For businesses seeking reliable AF glass solutions, WEIMAN TECHNOLOGY remains a trusted partner, delivering excellence through innovation and a commitment to quality.