Blog

AR Advance Coating Technology for Glass: Enhancing Performance and Applications

Introduction

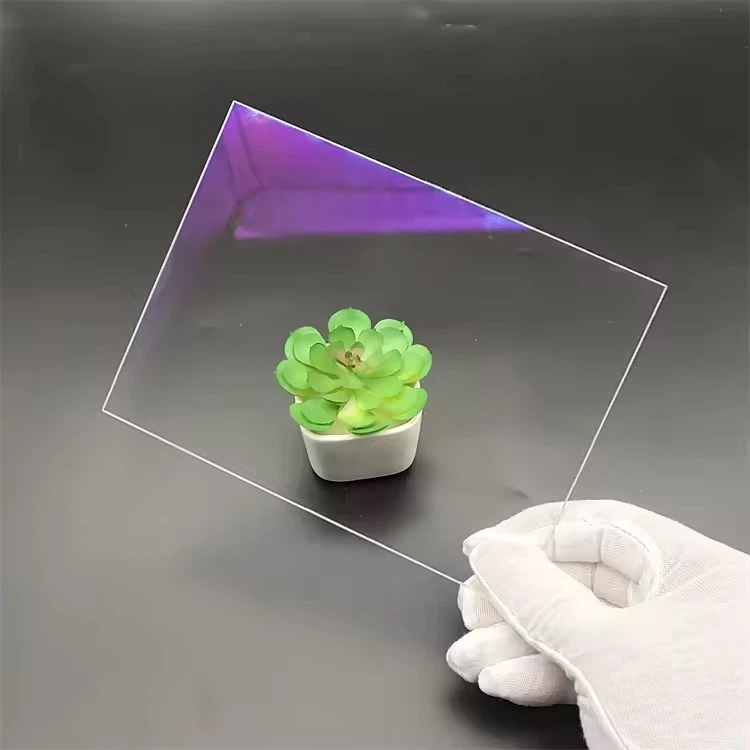

Anti-reflective (AR) coating is a critical optical technology that minimizes light reflection on glass surfaces, improving light transmission and reducing glare.

AR coatings are widely used in eyewear, camera lenses, smartphone screens, solar panels, and automotive displays.

Among various AR coating techniques, glass AR electroplating (AR coating via electrodeposition) has emerged as an efficient and cost-effective method for producing high-performance optical coatings.

1. What is Glass AR Electroplating?

AR electroplating is a deposition process where a thin, anti-reflective layer is applied to glass surfaces using electrochemical methods.

Unlike traditional vacuum-based AR coatings (e.g., magnetron sputtering or evaporation), electroplating offers a scalable, low-cost, and energy-efficient alternative.

Key Steps in AR Electroplating:

Surface Preparation – The glass is cleaned to remove contaminants.

Electrolyte Bath Immersion – The glass substrate is submerged in a solution containing metal ions (e.g., SiO₂, TiO₂, or ZrO₂).

Electrodeposition – An electric current facilitates the deposition of thin-film layers.

Post-Treatment – The coated glass undergoes curing and quality inspection.

2. Advantages of AR Electroplating on Glass

Compared to conventional AR coating methods, electroplating offers several benefits:

① Cost-Effectiveness

Eliminates the need for expensive vacuum deposition systems.

Suitable for large-scale production.

② Enhanced Optical Performance

Reduces reflectivity to <1% (compared to ~4% for uncoated glass).

Improves light transmission to >99%, ideal for high-precision optics.

③ Durability & Scratch Resistance

Electroplated AR coatings exhibit strong adhesion and wear resistance.

Can be combined with hydrophobic layers for easy cleaning.

④ Flexibility in Design

Allows multi-layer coatings for customized refractive index profiles.

Compatible with curved and complex glass geometries.

3. Applications of AR-Coated Glass

AR electroplating is used across multiple industries:

① Consumer Electronics

Smartphone & Tablet Screens – Reduces glare and improves sunlight readability.

Camera Lenses – Enhances image clarity by minimizing light loss.

② Solar Energy

Photovoltaic Panels – Increases light absorption, boosting energy efficiency.

③ Automotive & Aerospace

Windshields & Head-Up Displays (HUDs) – Improves visibility and reduces driver distraction.

Aircraft Windows – Enhances optical performance under varying light conditions.

④ Medical & Scientific Instruments

Microscope Lenses & Lab Equipment – Ensures high-precision light transmission.

4. Future Trends in AR Electroplating

The AR coating industry is evolving with advancements in:

Nanostructured Coatings – Further reducing reflectivity via nanoimprinting.

Self-Cleaning AR Layers – Combining anti-reflective and hydrophobic properties.

Sustainable Electroplating – Eco-friendly electrolytes and reduced chemical waste.

Conclusion

Glass AR electroplating is a highly efficient, durable, and cost-effective solution for anti-reflective applications. With its superior optical performance and versatility, it is poised to play a key role in next-generation displays, solar panels, and advanced optics.

By adopting innovative electroplating techniques, manufacturers can achieve higher performance at lower costs, making AR-coated glass more accessible across industries.