FAQS

Here answers you will feel interest to see

Pre-inquiry issues

Sure, we offer OEM/ODM service for glass customization including Material / Size / Printing / Coating / Tape base on your requirements.

Samples:3-5 working days

Orders: 10-15 working days

The actual finish date base on different technologies and will be offered in 1 working day.

We don’t have requirement on MOQ, both sample order and bulk order are welcome.

(The bulk order price is more cost effective because screen / jig etc are fixed expense)

Sure, we could offer stock samples for your verify as free.

Customization samples incur charge and it can be returned in mass production.

Our packaging way first protective 1.Film lamination, 2.EVA, 3.Carton, 4.Plywood box(No need fumigation) , we have been shipped oversea for 10 years without accident happen.

A.During design stage:

*What’s the glass application.

*The treatment requirements / What effect to meet.

*What’s the samples & order quantities.

(We could design a drawing including all discussed requirements for your verification)

B.Existing design / product:

*The drawing in CAD/Editable PDF, glass brand, thickness, tolerance and other treatments like silk print, chamfer, thermal / chemical tempered etc.

*Customization service like AR(anti-reflective), AG(anti-glare), AF(anti-fingerprint), 3M tape, film lamination etc.

*Both samples and order quantities.

A.If the problem caused by us no matter wrong production / unsafety package, we will take up our responsibility to solve including free replacement / refund.

B.If the problem caused by customer side, we could give some discounts to remake them.

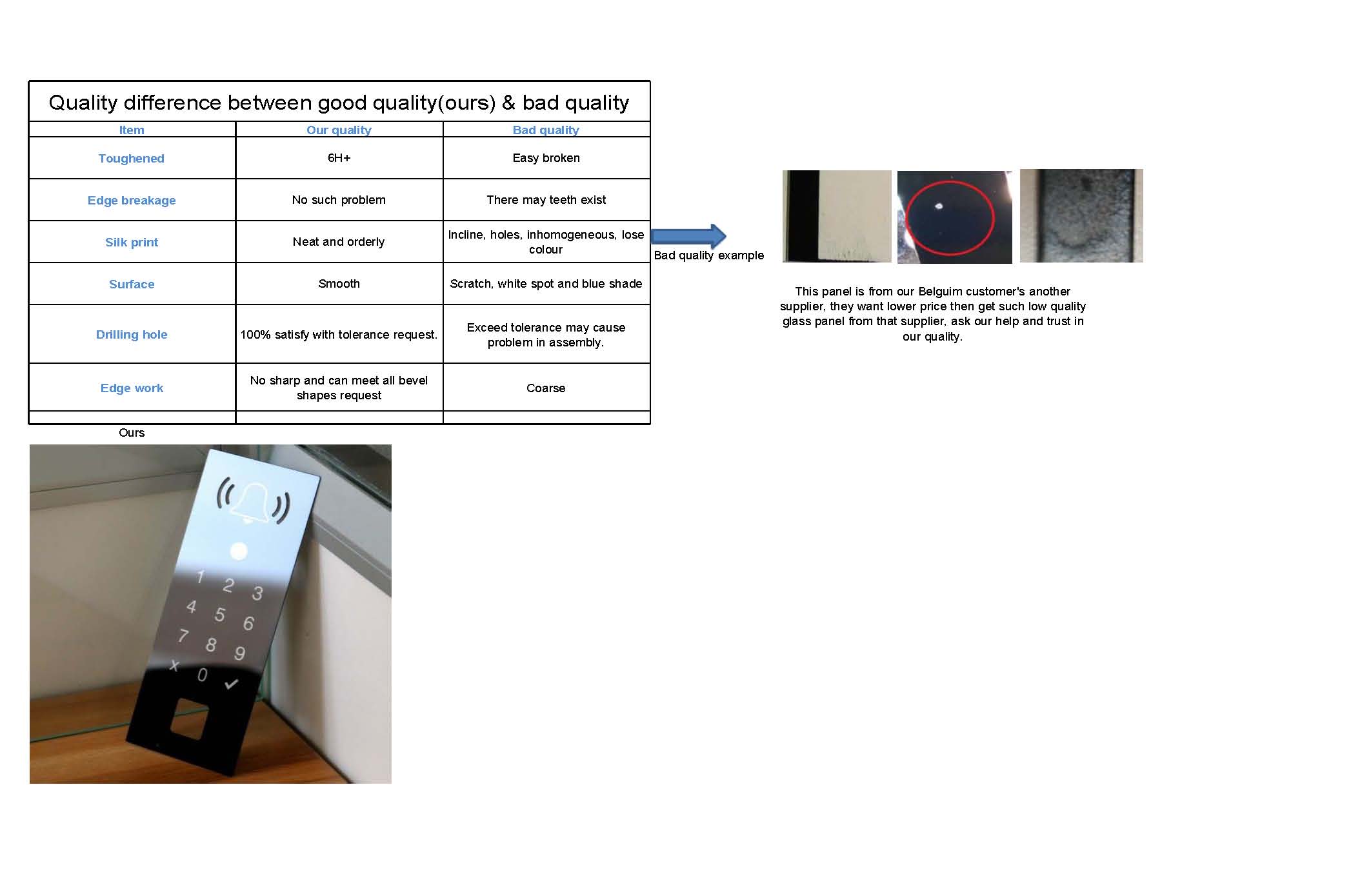

Weiman believes good quality, price and service not from speak out by ourselves but from other customers' true experiences.

Here are some comments from our customers.

1.This customer comes from US.

2.This customer comes from Italy.

3.This customer comes from US.

4.This customer comes from US.

5.This customer comes from Netherland.

We always believe customers' trust is the key factor to win long term cooperation.

Production service concern

Cutting → CNC(edge treatment/cut hole) → Tempering(thermal/chemical) → Silk print → tape adhesion → other surface treatment(AR/AF/AG etc).

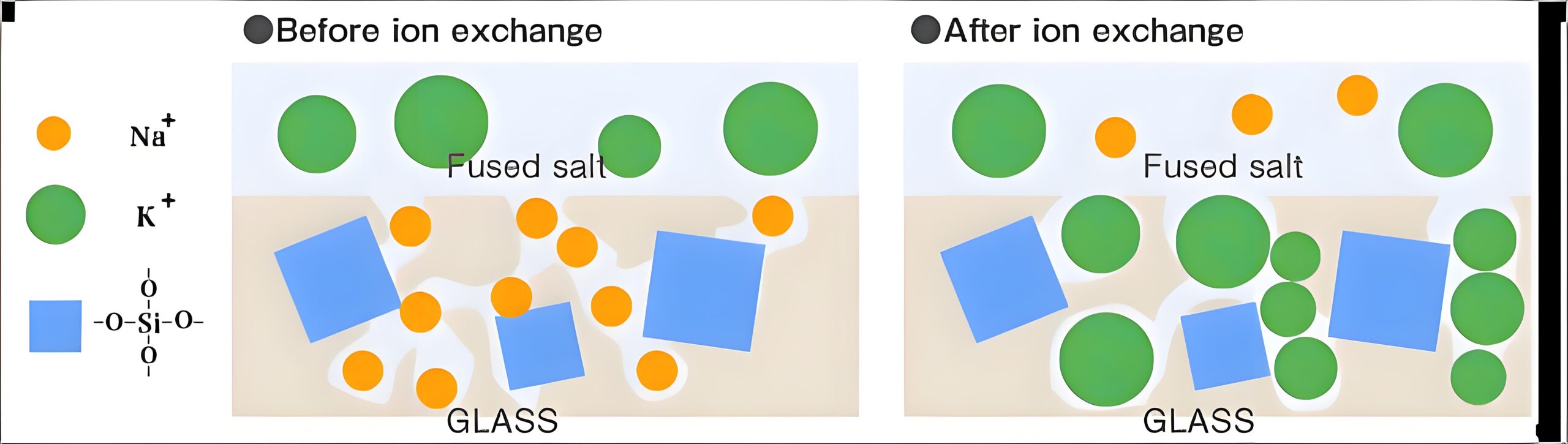

Thickness≤3.2mm, recommend chemical tempered(surface toughened meet 6~8H).

What's chemical toughened?(The picture tells)

Thickness≥3.2mm, recommend thermal tempered(safety glass, become particle when break)

What's the thermal tempered?(The picture tells you)

AR(Anti-reflective), can improve 3-4% light transmittance in single side.

AG(Anti-glare), different haze/transmittance optional.

AF(Anti-fingerprint), can improve the clean of glass, usually apply behind AR coating for protection layer purpose.

Tape, we offer different kinds of 3M or other brands tapes custom cut, adhesive to glass process to meet customer's need.

Also, we could offer anti-fog / anti-scratch treatments etc.

Payment & shipment

We could support T/T, Paypal, credit card, etc.

Samples:100% prepaid

Order: 30% deposit + balance before shipment.

Term:EXW, FOB, CIF

We have got our own agent cooperated for more than 15 years in sea / air / rail / express to guarantee the transportation safety, or your specify agent