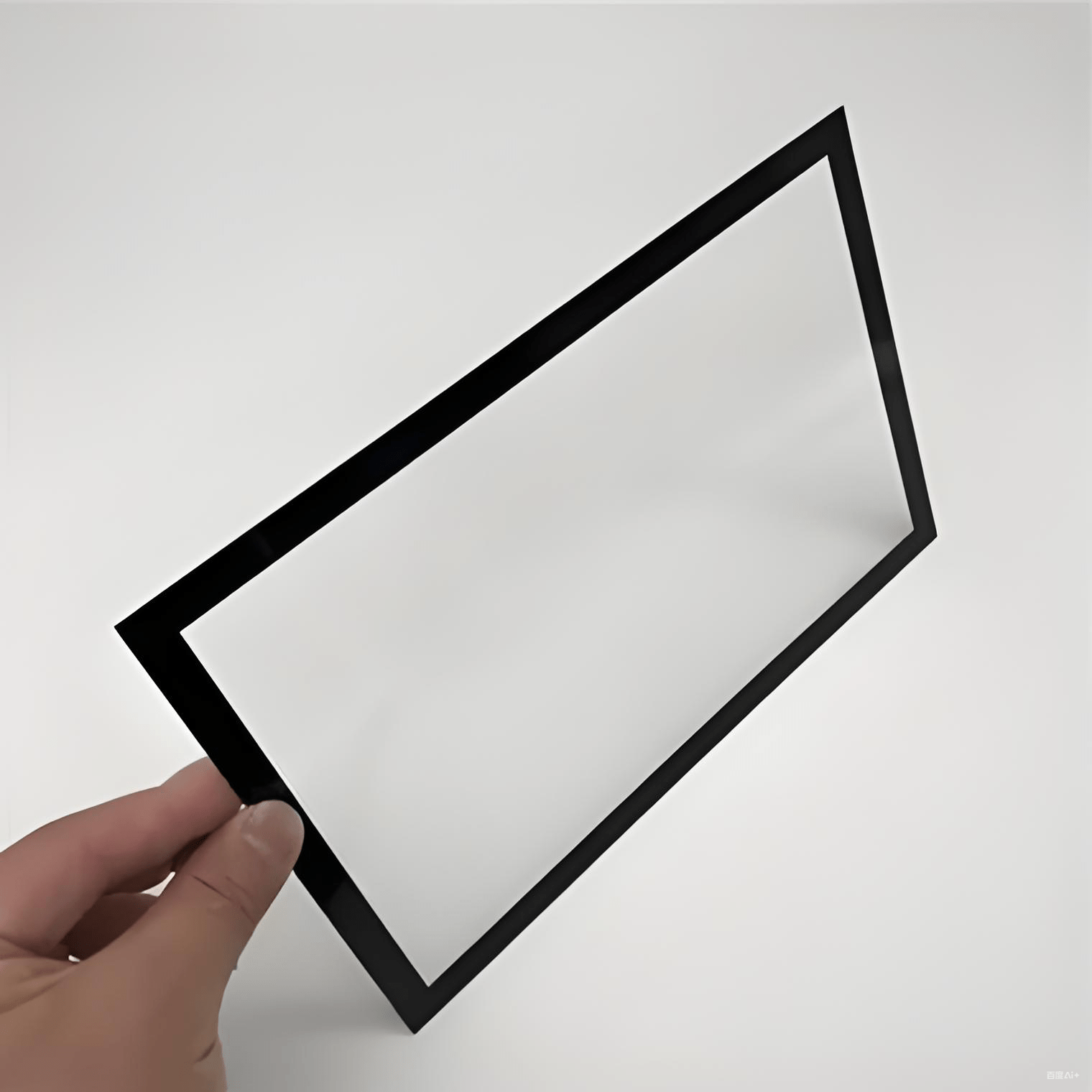

Your Design Our Glass – Custom Electronic Glass Made for Your Success

We make the custom electronic glass base on your exact specification. No matter you need unique shapes, specialize coatings or specific performance charachteristics, our glass can always fit to your application perfectly. For different industries, we deliver precision cutting, professionaly finish glass that meets your design requirements and quality.

Custom Electronic Glass Made for Your Success

We succeed what you design, we can make custom electronic glass to bring you unique product vision to real life. What you desire for special shapes, coatings, or specific perfomance features. We work with you to create the exact glass solution which product required and get pieces designed specifically success.

Custom Electronic Glass Applications

Medical Technology Applications

Patient monitoring device windows

Portable scanner display covers

Medical probe optical components

Industrial Automation Systems

Robotic sensor protection glass

Machine vision inspection windows

Control panel touch interfaces

Specialized Consumer Electronics

Wearable health monitor glass

Smart home control surfaces

Fitness tracker display protection

Automotive Technology

EV battery status indicators

Advanced driver assistance sensors

Vehicle connectivity interface panels

Aerospace & Defense Applications

Cockpit instrument covers

Military communication displays

Avionic system optical components

Research & Laboratory Equipment

Scientific instrument displays

Laboratory analyzer windows

Testing equipment viewing panels

Telecommunications Infrastructure

Network equipment status indicators

Fiber optic connection panels

Base station display interfaces

Marine Technology Applications

Navigation equipment displays

Underwater sensor protection

Ship control system interfaces

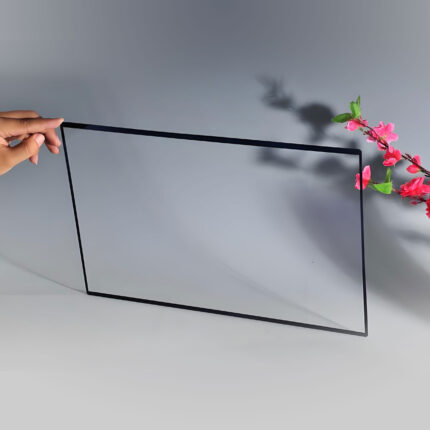

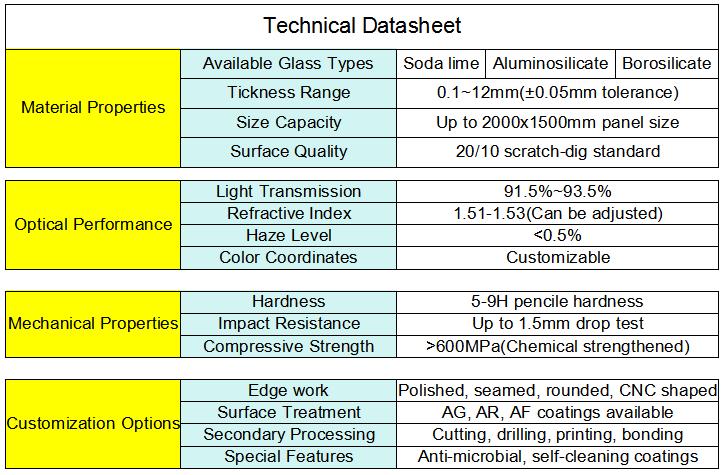

Parameters of custom electronic glass

Why choose Weiman as your custom electronic glass OEM?

At Weiman, we don’t just manufacture glass – we bring your vision to life. Our custom electronic glass solutions are tailored to your exact specifications, ensuring perfect integration with your product design. We work side-by-side with your team throughout the entire process, from initial concept to final production, developing innovative solutions that set your products apart in the marketplace.

Our comprehensive capabilities cover every aspect of glass customization, whether you need intricate shapes cut with precision or advanced functional coatings like anti-glare, anti-reflection, or anti-fingerprint treatments. As your dedicated partner, we ensure consistent quality and reliable performance for all your cover glass requirements.

What truly sets us apart is our commitment to engineering excellence. Every piece of glass we produce is meticulously crafted to enhance both the technical performance and visual appeal of your final product. We understand that great design requires perfect execution, and that’s exactly what we deliver – glass solutions that not only meet specifications but exceed expectations.

FAQ:

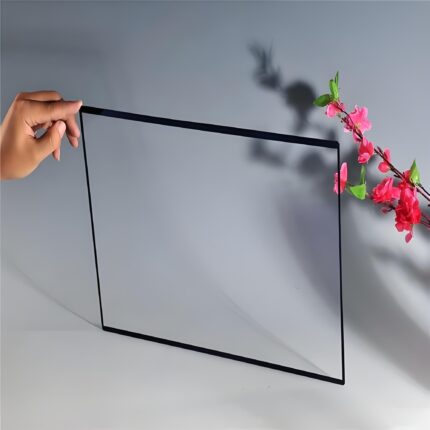

Q:What glass you will use?

A: It depends on customer’s need.

If hardness and quality not very high, we can choose domestic brand which commonly used.

If quality is required but hardness isn’t request high, we can consider some soda lime glass like AGC.

If both will be needed high, we can use gorilla glass, dragontail, Schott etc, but domestic brand in China like Panda will be a good but cheaper alternative.

Q:What kind of ink you will choose for silkscreen print?

A:For thickness less than 3mm, we usually use low temperature ink(resin), if there special requirement we can use UV resistance ink(a little higher cost).

For thickness more than 3mm, both low temperature ink(resin) and high temperature ink(ceramic) can be recommended, depends on actual application.

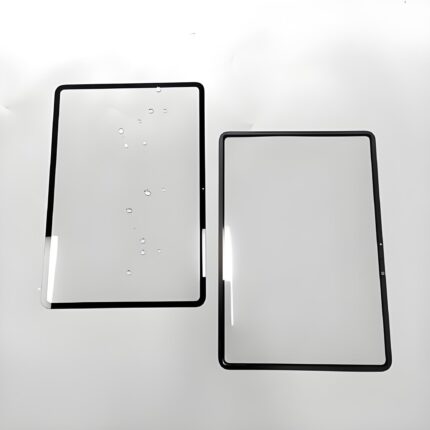

Q:Which kind of glass tempering applied?

A:For thickness lower than 3mm, we use chemical strengthened, it’s a kind of chemical reaction that glass surface makes hard.

For thickness more than 3mm, we recommend to use thermal tempered, which is safety glass that become particles when break.

Q:What kind of coating we can applied?

A:In market, usually AR(anti reflective), AG(anti glare) and AF(anti fingerprint) coatings but other requirement can also available depends on your demand.

Q:What’s the solutions of adhesive?

A:First, we can done with film lamination like anti explosive film, and we can done with 3M tape(or alternative), OCA glue or AB glue.