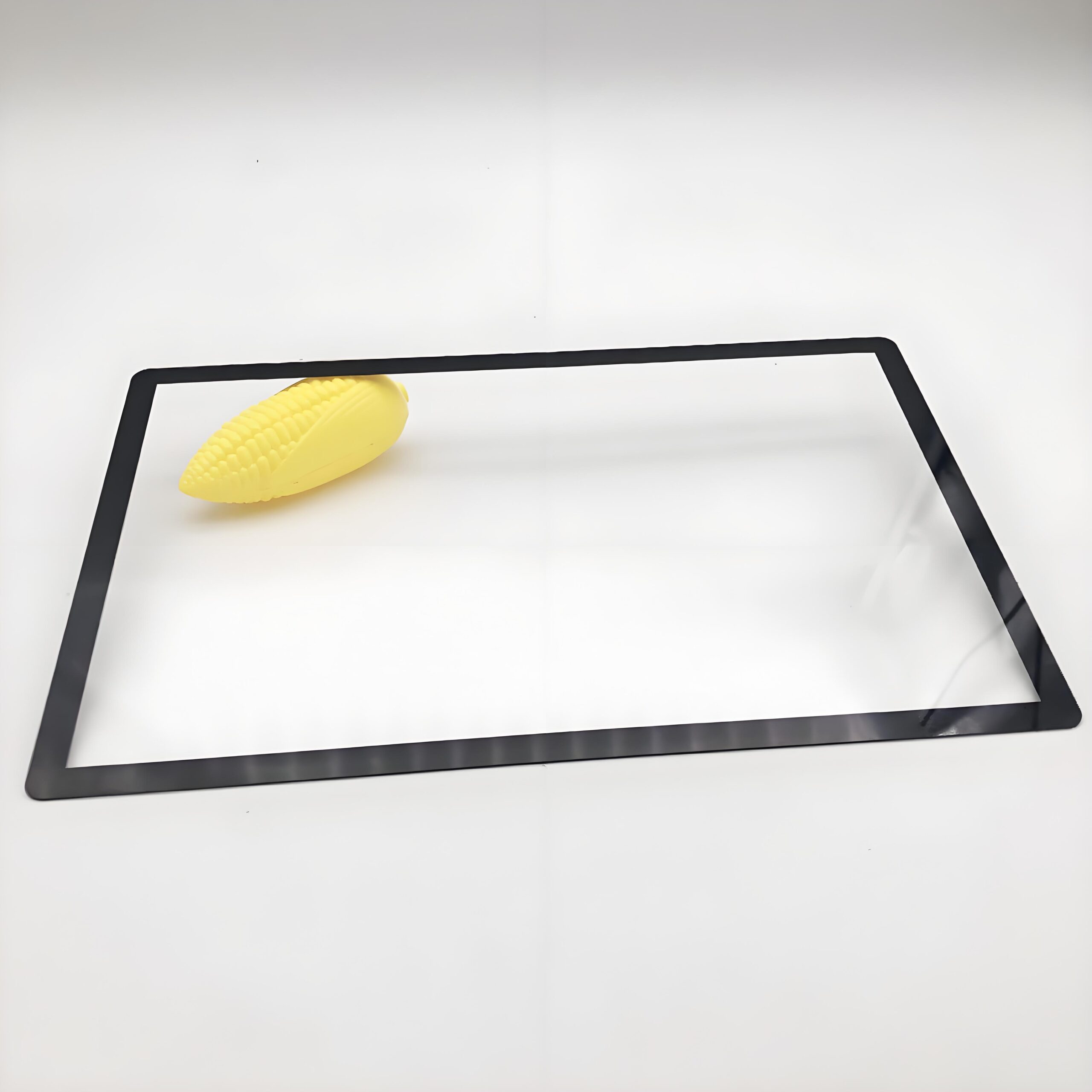

AGC Ultra-Thin Glass for Cover Glass

AGC ultra-thin glass delivers a premium cover glass solution, engineered for high-performance applications. We provide complete custom processing—precision cutting, chemical strengthening, and a range of durable, aesthetic PVD plating finishes like chrome and brushed metals. This combination of material excellence and advanced fabrication is ideal for creating distinctive, high-quality interfaces for consumer electronics, automotive displays, and smart home devices. Partner with us to integrate functionality and sophisticated design into your products.

Custom Processing and Production of AGC Ultra-Thin Glass for Cover Glass Applications

1. Introduction: The Role of Advanced Cover Glass in Modern Technology

In today’s high-tech landscape, the cover glass is far more than a passive protective layer. It is a critical component that influences optical clarity, touch sensitivity, durability, and the overall aesthetic appeal of a device. As products from smartphones and tablets to automotive displays and smart home interfaces become more integrated into our lives, the demand for superior cover glass has skyrocketed. Manufacturers and designers increasingly seek partners who can provide not just raw materials, but fully customized solutions that meet exacting specifications. This is where AGC (Asahi Glass Co.), a global leader in glass innovation, enters the picture with its exceptional ultra-thin glass, offering a canvas for high-performance and highly customized applications.

2. AGC Ultra-Thin Glass: A Premium Material Foundation

AGC’s ultra-thin glass, such as their renowned Dragontrail™ or other high-performance alkali-aluminosilicate sheets, provides an outstanding foundation for cover glass applications. This material is engineered for exceptional characteristics that are paramount for modern devices:

-

Exceptional Thinness and Lightness: AGC produces glass substrates that are remarkably thin—often below 0.5mm—enabling sleek, lightweight designs without compromising structural integrity. This is crucial for next-generation foldable devices and wearables.

-

High Mechanical Strength: Through advanced chemical strengthening processes, the glass achieves superior resistance to scratches, impacts, and drops. This translates directly into improved product durability and reduced failure rates.

-

Excellent Optical Properties: The glass offers high light transmittance and low haze, ensuring brilliant, clear images without distortion. This is non-negotiable for high-resolution displays and camera lens covers.

-

Superior Processability: Despite its strength, AGC’s ultra-thin glass is highly workable. It can be precisely cut, edged, drilled, and shaped using advanced CNC and laser machining techniques, allowing for complex geometries and tight tolerances required for custom designs.

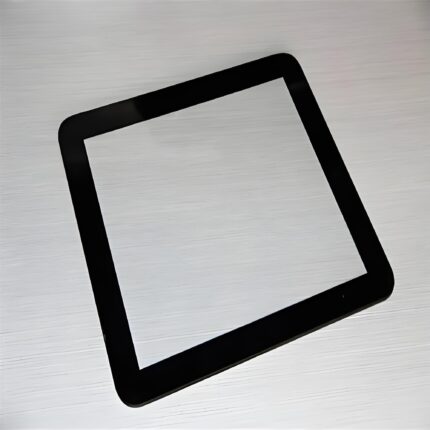

3. Advanced Custom Processing: Beyond the Basic Cut

The true value for OEMs comes from the custom processing that transforms raw glass sheets into finished, application-ready components. Specialized manufacturers offer a comprehensive suite of precision fabrication services tailored to AGC glass.

-

CNC Machining: Computer Numerical Control (CNC) grinding and cutting allow for the mass production of parts with complex shapes and precise cut-outs for buttons, sensors, and cameras. Tight radius edges and smooth, polished finishes are achieved consistently.

-

Precision Edging: The edges of the glass can be processed to various profiles—such as flat, round, or 2.5D—which affect both the feel and the visual appeal of the final product.

-

Tempering and Strengthening: While the base material is already strong, secondary chemical strengthening processes can be applied post-machining to ensure the edges and any drilled holes possess the same high surface compression as the rest of the panel, guaranteeing uniform durability.

-

Surface Treatments: Additional functional coatings can be applied, including Anti-Reflective (AR), Anti-Glare (AG), Anti-Fingerprint (AF), and Oleophobic layers. These coatings enhance usability, improve readability in various lighting conditions, and make devices easier to clean and maintain.

4. Enhancing Aesthetics and Function: Custom Plating Finishes

A significant differentiator in the market is the ability to apply sophisticated metallic finishes through advanced plating techniques. This process involves depositing a thin layer of metal onto the glass perimeter or specific areas, merging glass’s elegance with metal’s luxury.

-

Vacuum Metallization (PVD): Physical Vapor Deposition is a high-tech vacuum coating process used to create thin, ultra-adherent, and uniform metallic layers. It offers exceptional durability, corrosion resistance, and a brilliant aesthetic finish.

-

Available Finishes: The range of achievable effects is vast, allowing designers to perfectly match the glass to their product’s brand identity. Common options include:

-

Chrome: Delivers a bright, mirror-like, modern silver finish.

-

Brushed Nickel/Gold: Provides a subtle, linear textured look that reduces the visibility of fingerprints.

-

Satin and Matte Finishes: Offer a soft, non-reflective luxury feel.

-

Colorful PVD: Advanced processes can create vibrant gold, rose gold, black chrome, and even blue or gunmetal hues.

-

-

Functional Benefits: Beyond aesthetics, the metallic layer can serve as an electromagnetic interference (EMI) shield, grounding plane, or an antenna pathway, making it a key enabler for advanced electronic integration.

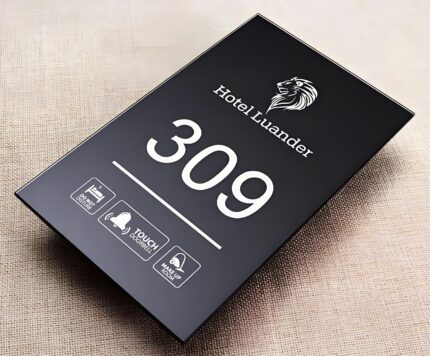

5. Application Scenarios: Where Custom Glass Excels

The combination of AGC’s material excellence and sophisticated custom processing opens doors across numerous high-value industries.

-

Consumer Electronics: This remains the core application. Custom-shaped, strengthened, and plated cover glass is used for smartphones, tablets, smartwatches, fitness trackers, and VR/AR headset lenses. The plating is often used on bezels or watch lugs to create a premium, jewelry-like appearance.

-

Automotive Interiors: Modern vehicles are rolling tech hubs. Custom glass is used for instrument clusters, center stack touchscreen displays, rear-seat entertainment systems, and control panels. The ability to create complex curved shapes and apply anti-glare coatings is critical here. Plated borders can integrate seamlessly with other metallic trim elements in the cabin.

-

Smart Home and IoT Devices: From smart thermostats and refrigerator doors to voice-controlled assistants and security system panels, these products benefit from durable, scratch-resistant glass that provides a high-end user interface. A subtle plated bezel can elevate the product’s perceived quality.

-

Medical and Industrial Equipment: These sectors require robust, easy-to-clean, and chemically resistant interfaces. Cover glass with anti-bacterial coatings and robust construction is essential for touchscreens in hospitals, factories, and laboratories.

6. Conclusion: Partnering for Innovation

Selecting AGC ultra-thin glass is a decisive first step toward creating a superior product. However, fully leveraging its potential requires a partnership with a expert manufacturing provider capable of executing the complex downstream processing and finishing. By integrating precision machining, functional enhancements, and aesthetic plating, brands can transcend the ordinary. They can deliver devices that are not only more reliable and functional but also possess a distinct tactile and visual identity that resonates with consumers. In a competitive market, this level of customization is not just an option—it is a strategic imperative for product differentiation and success.